Adjustments to compensate for wear, Adjustments to conipensate for wear – Sears 113.19771 User Manual

Page 28

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

adjustments to compensate for wear

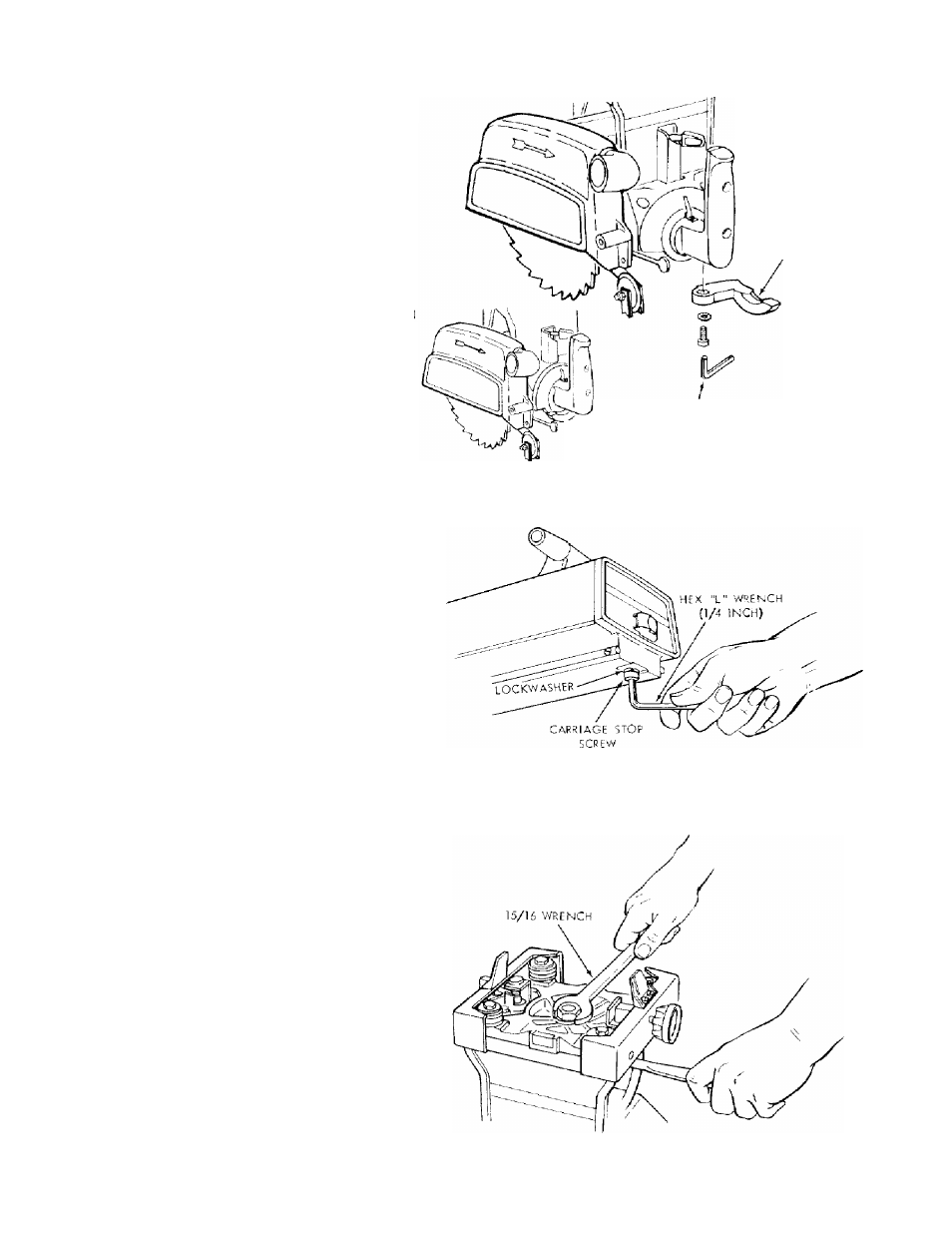

ADJUSTING BEVEL LOCK LEVER

1.

The purpose of this lever s to lock the motor at any

angle To adjust, remove the set screw with wrencli as

shown. Use the bevel lock lever as a wrench to tighten

The clamp bolt. Do Not Over Tighten. Replace bevel

lock lever in locked position and tighten the set screw.

NOTE: The clamp bolt has a left handed thread. Therefore,

to increase the clamping effect, rotate the bevel lock lever

— when used as a wrench — from right to left, or clockwise

when viewed from above. If you accidentally rotate it the

wrong way and disengage the bolt from the matching stee

nut, it will be necessary to remove the Handle Trim, Yoke

Handle, and Bevel Scale, in order to reinstall the bolt in the

nut.

BEVrL LOCK

LEVER

1/3 HEX 'L" WRENCH

BEVEL LOCK LEVER

IN LOCKED POSITION

YOKE LOCK HANDLE ADJUSTMENT.

2

.

3.

4.

This handle provides a friction lock between the upper

*ace of tfie yoke and the bottom face of the carriage.

It should eliminate any play or rotation between these

two

parts

when

locked.

Its

proper

position

for

saw

operation

is

approximately

midway

between

the

two

sides of the yoke.

When sufficient wear has occured to pernnit the handle

to move considerably to the rear, or strike the yoke

before locking, the handle must be adjusted as follows:

Remove carriage stop screw and lockwasher with a 1/4

inch hex-L wrench.

Grasp the carriage assembly, move it carefully off the

end of radial arm, holding it parallel to the radial arm

until all carriage bearings are tree of their tracks.

Rest the motor and carriage assembly on saw work

table and re install carriage stop screw and lockwasher.

To Readjust

5.

Set yoke lock handle at unlocked position. Tighten nut

with

15/16

wrench,

until

lock

handle

locks

mid-way

between the two sides of the yoke. Remove carriage

stop screw and lockwasher.

6.

Hold the motor and carriage assembly parallel to radial

arm

and

start

the

rear

bearings

onto

the

tracks.

Continue to hold the assembly parallel to the tracks

until the forward bearings are on the tracks.

7.

Slide the carriage rearward on the radial arm and

INSTALL

THE

CARRIAGE

STOP

SCREW

AND

LOCKWASHER.

28