Trouble-shooting and maintenance – Sears 831.159341 User Manual

Page 26

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

TROUBLE-SHOOTING AND MAINTENANCE

Inspect and fighlen alt parts each time you use rfie CROSS TRAINER e. Replace ony worn parts immediately. Outside

surfaces of the CROSS TRAINER e con be cleaned using a damp cloth and mild detergent. Keep all liquids away from

the stepper console and the PERSC^

n

IAL TRAINER computer. Most CROSS TRAINER e [Hx>blems can be solved by h>llow-

Ing the steps below. Find the applicable symptom and follow the step(s) listed. If further assistance is needed, call our

Customer Service Department toll-free ot 1-800-999-3756, Monday through Fridoy, 6 a.m. until‘6 p.m. Mountain

Time (excluding holidays).

1. SYMPTOM: THE PERSONAL TRAINER COMPLTTER DISPLAYS AN ERROR CODE ("EEE")

a. While the weight setting is changing, the motor will be heard and the SETS and REPS displays will show a rapidly

rotating indicator. To prevent damoge to the weight system, do not put any pressure on the leg developer, arms

or cobles while the weight setting is changing. If the lot bar or rower bar is attached to the high pulley station, rest It

in the rock neor rfie high pulley stotlon. Wait for.the sound of the motor to stop before you continue. If the comput

er senses pressure on the weight system while the weight setting is changing, the WEIGHT display will show on

error code ("EEE") for two seconds, and the weight setting vnTI stop changing. The WEIGHT display will then show

the current weight setting. Make sure that there is no pressure on the leg developer, arms or cables. Press the

increase or decrease button beneath the WEIGHT display to chonge the weight setting as desired.

2. SYMPTOM: THE MAIN CABLE DOES NOT MOVE SMOOTHLY, OR THERE IS SLACK IN THE MAIN CABLE

a. Inspect the routing the cables and moke sure thot they are In the grooves in all of the pulleys. If they are not,

correct the problem. If the cables are not properly routed, they will be danxiged when us^..

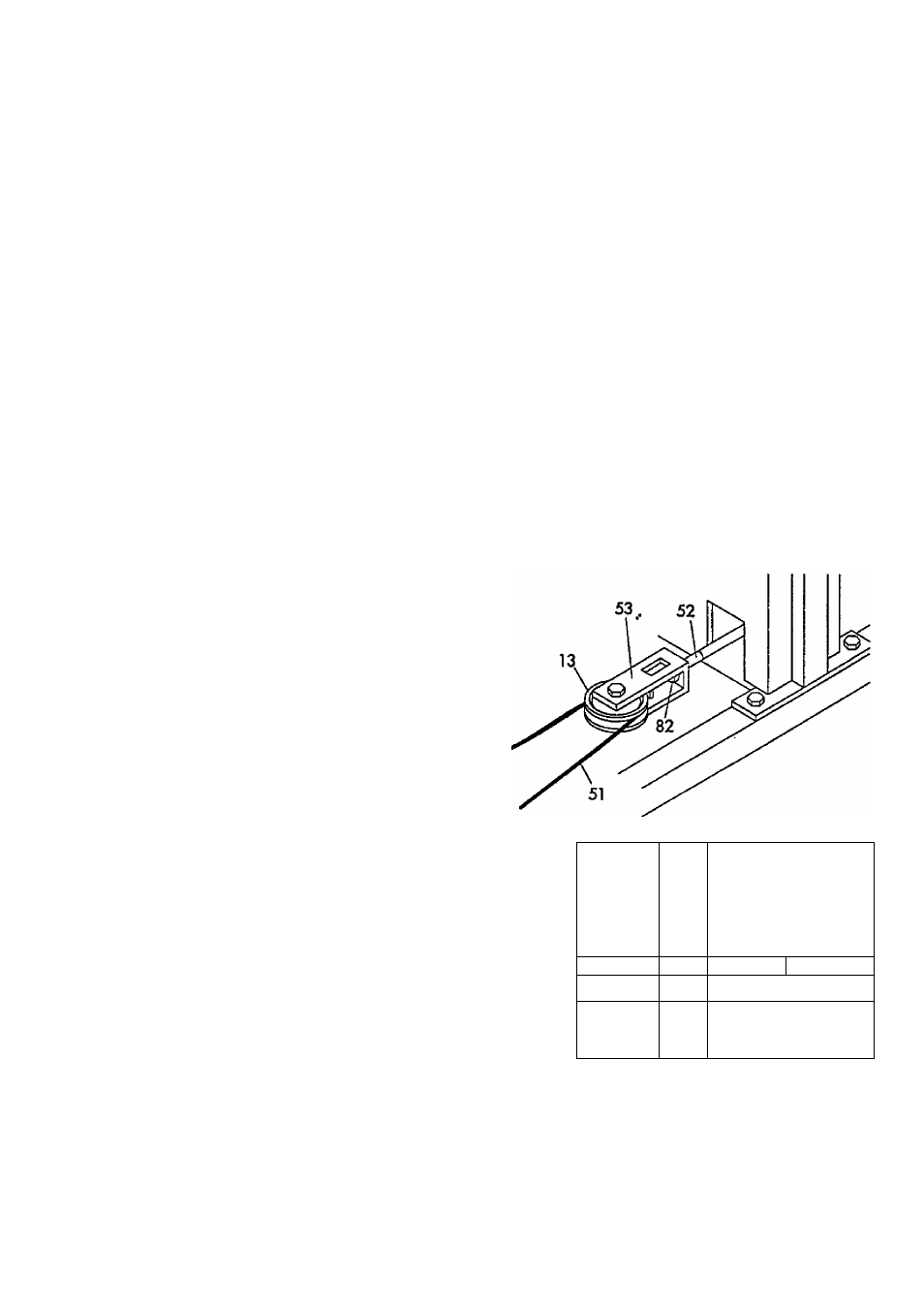

b. If there Is slack in the Main Cable (51), locate the

Adjustment Brocket (53) neor the bottom of the

. right side shield. Hold the end of the Weight Cable

-

(52) firmly, and slide the Adjustment Bracket for-

ther onto the Weight Cable. Tighten the 5/16" Nut

(82) ogainst the Adjustment Bracket. Test the Main

Cable. If the motor stalls or hesitates, loosen the

5/16* Nut slightly. If the 5/16" Nut is tightened as

for as possible and there is still slock, the Main

Coble should be replaced. See ORDERING

REPLACEMENT PARTS on the back cover of this

owner's nrtanual.

3. SYMPTOM: THE STEPPER CONSOLE DOES NOT

FUNCnON PROPERLY

o. As you step, move the stepper pedals vertically at

least 8 inches. If your steps ore too shallow, the

movement of the stepper pedals will not be detect

ed. If the stepper console still does not function

properly, the Reed Switch (99) can be adjusted by

slidir^ the barrel of the Reed Switch up and down

slightly. Repeat until the stepper console displays

correct feedback. If necessory, the 3/4' Screw

(119) attaching the Reed Switch Bracket (120) can

be loosened ond the position of the Brocket con be

adjusted.

120^

99

/

LL. _1

n/'

\

Mounting

Sleeve

25