Carrier 48MA User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

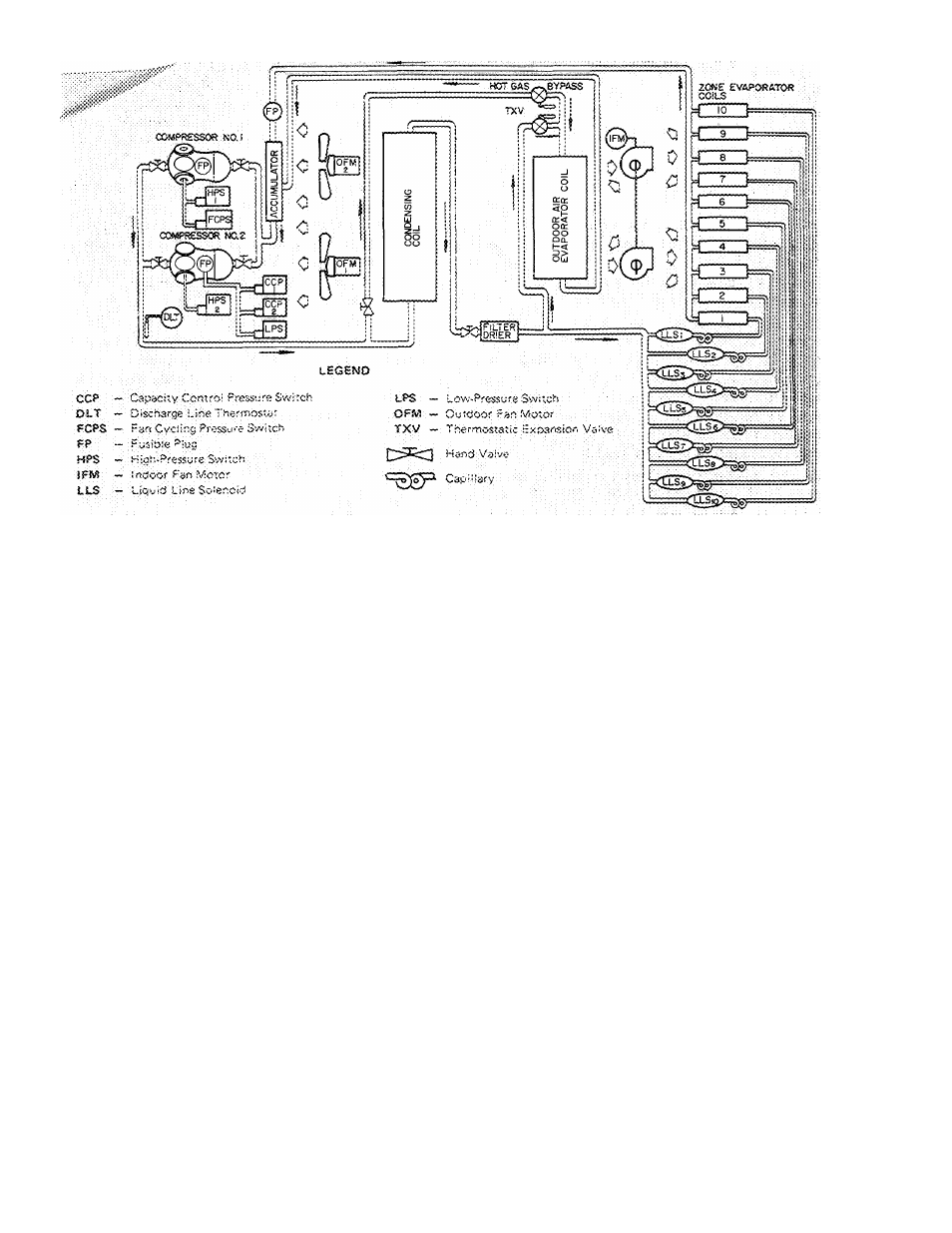

Fig. 1 — Refrigerant Piping Schematic (10-Zone Units Shown, 8- and 12-Zone Units Similar)

partial load operation, difficulties arise in conven

tional hot deck/cold deck units. When some zones

are at full heat, some at partial heat, some at

partial cooling, conventional multizones must

operate the hot and cold decks simultaneously at

high energy cost. The Carrier Modular design

satisfies each zone’s demand by a discrete

module(s). There are no hot decks, cold decks or

zone air mixing dampers to waste energy. The only

energy expended is that required to heat or cool

the individual zone. Since there is no mixing,

energy is saved and operating costs are significantly

lowered. In addition, the control system provides

excellent humidity and temperature control. Multi

stage cooling is available on larger zones where 2 or

more modules are used for efficient control of

zone space requirements.

The following features and safety devices are

provided on the refrigerant cycle:

1. Suction line accumulator

2. Crankcase heaters

3. High- and low-pressure switches

4. Discharge line thermostat

5. Time Guard® circuit

6. Airflow switch for indoor fan motor

7. Internal motor protection thermostats em

bedded in compressor motor windings

8. Hot gas bypass capability

9. Compressor unloading capability

10. Filter-driers

PSYCHROMETRICS ^ The 48MA/50ME units

differ psychrometrically from the conventional

multizones due to the operation of the outdoor air

coil. The coil in the Carrier units cools and

dehumidifies the outdoor air entering the unit thus

assuring that raw outdoor air is not passed along to

the zones. This air treatment by the outdoor air

coil (and also by the zone module evaporator coils)

provides excellent low load performance and

precise temperature control to the conditioned

space. The only large load variation occurs on the

outdoor air coil where a thermal expansion valve is

used. This allows the use of simple capillary tube

expansion devices on the zone coils. The zone coils

cool and dehumidify a mixture of return air and

outdoor air — outdoor air at the approximate dew

point temperature of the return air.

The psychrometric chart (Figure 2) illustrates

this air treatment for a typical set of conditions. As

an example: 1000 cfm of outdoor air at 95 F/75 F

having 99 grains moisture content enters the

outdoor air coil and is cooled and treated so that

the air leaving the coil has 68 grains of moisture

content. The outdoor air coil under these con

ditions has a capacity of 60,000 Btuh of which

39,000 Btuh is sensible. This is a coil sensible heat

factor of 0.65. By examining the room conditions,

it is evident that the outdoor air coil is very

effective in removing the latent load. At 75 F/50%,

the room content is 64 grains of moisture. The

percent moisture removed with respect to room

conditions is: