Miscellaneous – Carrier 48MA User Manual

Page 21

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Again, 2 jumper wires have to be removed from

the back of the remote panel to isolate the

day/night switch.

MORNING START-UP — To conserve energy and

lower total operating costs, the outdoor dampers

may be closed when starting the system in the

morning. During a warm-up period, when the

system is operated for one or two hours before

occupancy, only building return air should be

heated. The extra load of cold outdoor air intro

duced uses extra heat energy. Ventilation is

unnecessary until space is occupied, so the air

introduced produces unnecessary heat waste.

The same principle holds true on a cooling day,

when outside air transmits heat and moisture to

the evaporator coil. This extra load above the

return air only load is an unnecessary expense.

This can be offset by wiring a heating or

cooling thermostat across the “Short To Close

Dampers” terminals on the zone control board.

The thermostat senses return air temperature and

the outdoor air damper does not open until the

building is at the required temperature.

A time clock can also be used and set as

follows:

1. Occupied cycle: 8 a.m. to 6 p.m. Outdoor air

damper is open and the system is controlled by

individual zone thermostats.

2. Night setback cycle: 6 p.m. to 6 a.m. Individual

zone thermostats are on night setback (NS)

cycle. The outdoor air damper is closed, the

unit is reset down and controlled by NS

thermostat.

3. Warm-up (or cool-down) cycle: 6 a.m. to 8 a.m.

Outside air damper is closed by time clock and

the system is controlled by indoor zone

thermostats.

Using any method, increased economy is

achieved and building requirements are satisfied.

MISCELLANEOUS

Sound and Vibration

— All roof mounted air

conditioning equipment produces sound and vibra

tion. On light types of roof construction, sound

and vibration may be transmitted directly to the

occupied space. Accordingly, sound attenuation

and vibration isolation are important design con

siderations on any rooftop application.

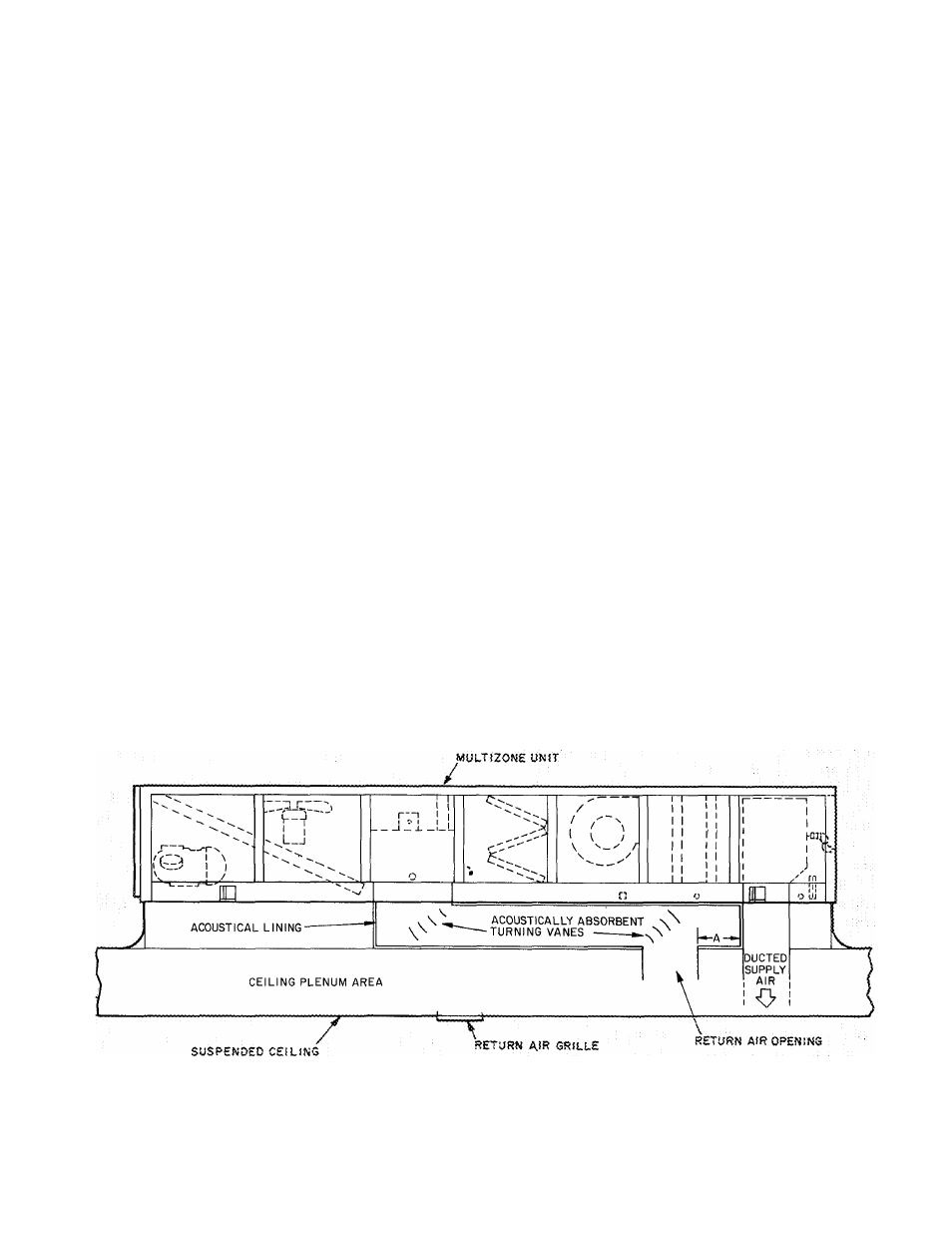

Sound attenuation can be accomplished in

many ways depending on the specific design

construction of the building. Roof mounted units

can be located over unoccupied space (i.e. storage

areas, utility rooms, corridors) where slightly

higher sound levels are not objectionable. Supply

and return duct systems can be acoustically lined

to prevent sound transmission into occupied space.

If open plenum return air systems are used, an

acoustical trap or fiberglass-lined chamber can be

used to attenuate the sound. Simple return duct

elbows and tees with 5-ft minimum fiberglass lined

legs and low static pressure drop should be

considered when using open plenum return air

systems. Figure 23 illustrates a procedure for

forming an acoustical trap using the roof curb area

under a 48MA unit.

NOTES:

1 Dimension A is approximately 7 in for optimum performance

2 Acoustical lining is 1-in 1-lb density, neoprene-coated fiberglass

3 Return air grille should be located at least 15 ft from return air opening

Fig. 23 — Acoustical Trap Installation

19