Economizer and exhaust performance — an, Economizer and exhaust performance – Carrier 48MA User Manual

Page 14

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

OA

damper

adjust

MIXED AIR THERMOSTAT

MOTOR POT

LEGEND

CHR

— Crankcase Heater Relay

ECR

— Economizer Relay

LAT

— Low Ambient Thermostat

OA

— Outside Air

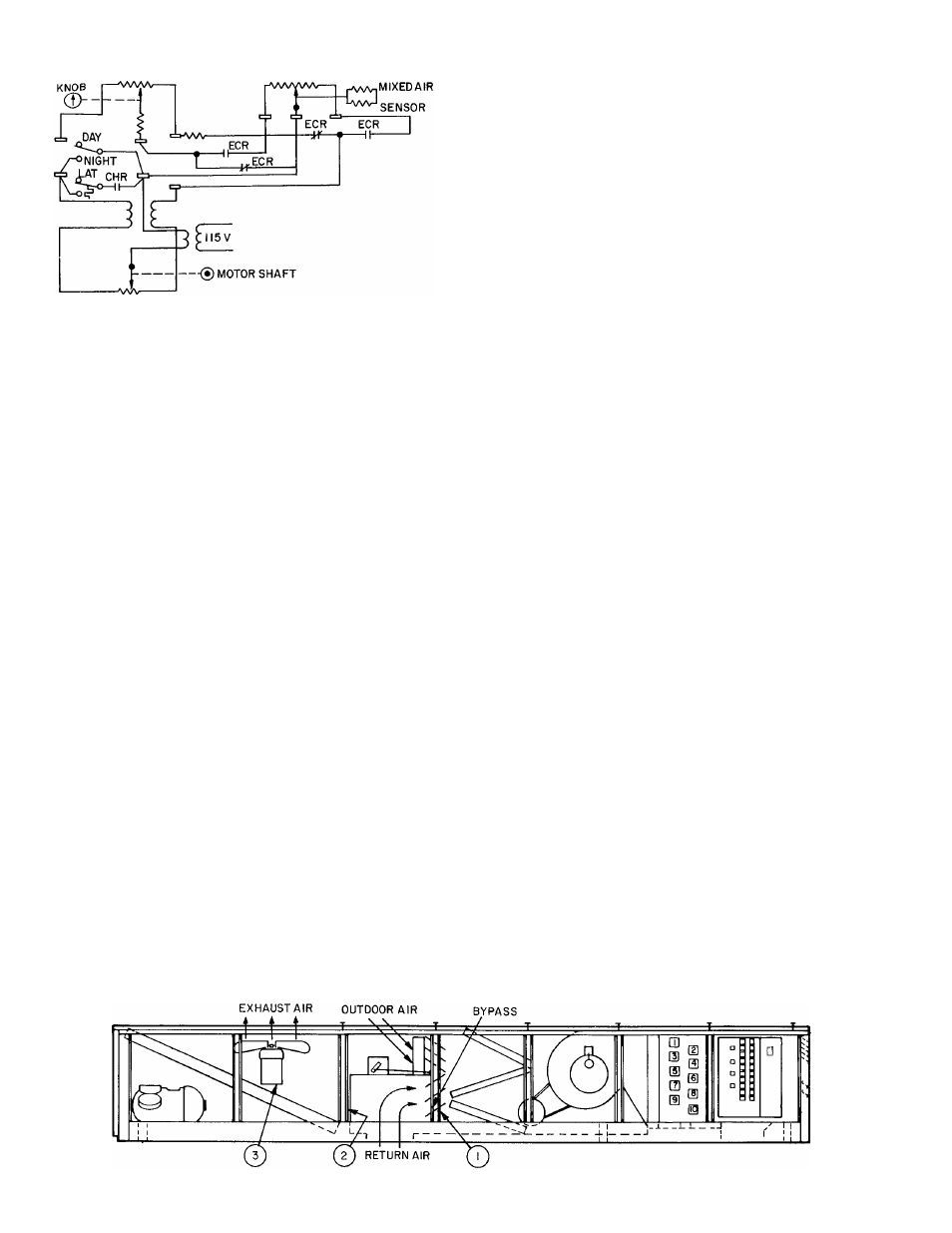

Fig. 15 — Economizer Damper Control Schematic

Economizer And Exhaust Performance

— An

economizer can be readily factory installed on the

48MA/50ME since the damper motor and outdoor

air damper are standard equipment. The econo

mizer package consists of a return air damper,

linkage, plug-in relays, MAT. wiring, and mixed air

thermostat.

When the 48MA/50ME unit is on full econo

mizer control, the supply cfm to the space drops

off slightly since the resistance of the outdoor air

intake is generally greater than that of the return

air ductwork. To partially offset this, the return air

dampers have a built-in bypass.

With the outdoor air dampers fully open and

the return air dampers fully closed, the total cfm

drops 15%. The total cfm consists of 70% outdoor

air and 30% return air thru the built-in bypass. If,

for example, the unit normally operates at

10,000 cfm supply air, the minimum supply cfm

when the economizer is operational is 8500. This

8500 cfm consists of 6000 cfm outdoor air and

2500 cfm return air. As the ambient temperature

drops from 48 F (recommended economizer set-

point), the proportion of outdoor air to the supply

air required to maintain mixed air temperature is

less, the outdoor air damper begins to close, and

return air damper begins to open (see Fig. 13). As

this happens, total supply cfm progressively

increases from 8500 cfm to 10,000 cfm (design).

An exhaust damper option is also available for

use with the economizer. It is located between the

return air plenum and the condenser fans. The

option consists of a TPDT plug-in relay (EXR), an

exhaust damper, and a plug-in jumper. The damper

provides a forced exhaust of indoor air during the

economizer operation. The exhaust damper opens

when the return air damper is 25% closed. With the

damper installed, ECR and EXR are energized

simultaneously. The EXR locks out outdoor fan

motor (OFM) controls (32LT on OFMl and FCPS

on OFM2 and OFM3) and outdoor (condensing)

fan motors operate at full speed, discharging excess

return air to the atmosphere thru the open exhaust

damper (see Fig. 16).

The 48MA/50ME exhaust operation is similar

in performance to a relief damper except that the

exhaust dampers are mechanically linked to the

return air dampers and the condenser fans operate

to produce a pressure differential which aids the

exhaust cycle. At approximately 0 in. wg at the

return air opening, the 48MA/50ME units exhaust

between 150 to 200 cfm/ton. With positive return

static, more air is exhausted. At -0.40 in. wg

(.25 in. wg on the 016 unit) return air static,

exhaust capabilities of the units drop to zero.

In the example, the 4000 cfm exhausted at

0 in. return static accounts for all but 1100 cfm

outdoor air introduced by the economizer outside

air section. In practice, this excess cfm is con

sidered a nominal ventilation rate, slightly pres

surizing a building to eliminate drafts and

unwanted air seepage. This excess air filters out of

the building thru doors and window spaces. The

^slight positive pressurization of the building aids

the exhaust fans in removing air. If, however, the

balance between the building static and exhaust

system leaves the building with unacceptably high

positive static pressures, a relief ventilator or roof

power exhauster may be used. For extensive or

SEQUENCE:

1

— Return damper closes 25%.

2 — The exhaust damper opens

3 — The OFM (condensing fans) speed controls are bypassed and

fans run full speed, exhausting return air to atmosphere

Fig. 16 — Exhaust Damper Operation

14