Table 1 — physical data – Carrier 48MA User Manual

Page 2

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

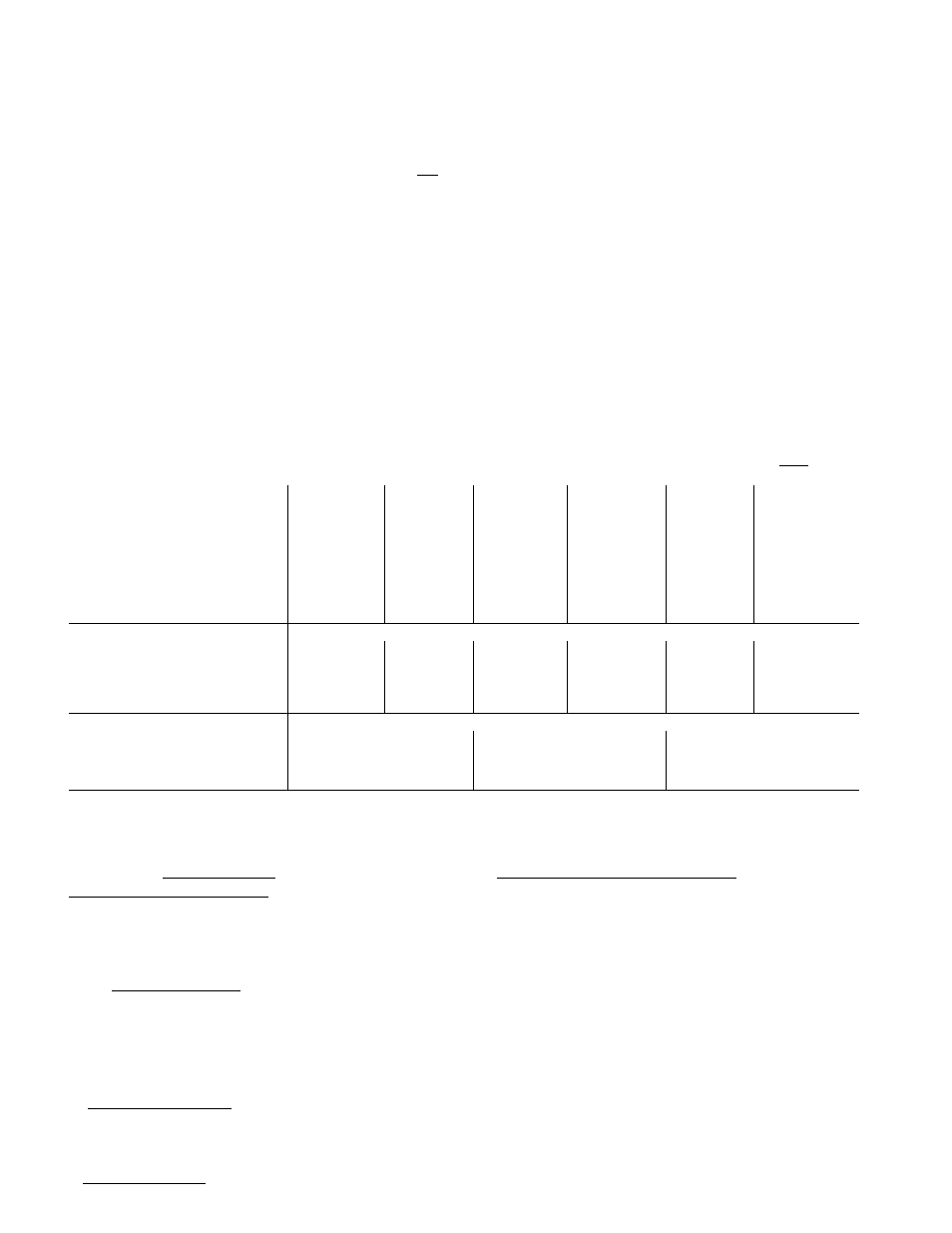

Table 1 — Physical Data

UNIT 48MA OR SOME

Zone Modules

OPERATING WT (lb)

Bose Unit 48MA

Bose Unit SOME (with heat)

Roof Curb

REFRIG CHARGE (lb, R-22)

COMPRESSOR

No. 1 Type

Cylinders ... Unloaders

No. 2 Type

Cylinders (has no unloaders)

System Oil Charge (pts)

Unlaader Settings (psig)

Left Bank

Right Bank

Loads

Unloads

Loads

Unloads

Capacity Steps (%)

OUTDOOR AIR FANS

Mtr Hp ... Rpm ... Frame (NEMA)

No. 1

No. 2

No. 3

0T6

8

3385

2985

_506

28 "

024

8

3805

3405

506

~~32

028

10

4075

3665

506

43

030

10

4080

3670

506

43

034

12

4800

4400

630

040

12

57

5700

5250

630

"65 “■

Reciprocating Hermetic, 1725 Rpm

06DE537

6 2

06 DE 824

6 .. 2

06DA824

6

22

06DE537

6

.

2

06DA824

6

22

06DE537

6

. .

2

06DA537

6

22

06DE537

6

. . .

2

06DA537

6

21

06EE250

4 . . 1

06EA250

4

31

Compressor No. 1 Only

71.0 ± 1 5

57.5

±25

76 0 + 1 5

62 5 ± 2.5

75.5 ± 1 5

58.0 ±25

100,67,33

100,83,67

50,33,17

100,80,60

40,20

100,80,60

40,20

100,83,67

50,33,17

100,75,

50,25

Propeller, Direct Drive

INDOOR AIR FANS

HEATING SECTION (48MA)

Rise Range

Input (1000 Btuh) Min-Max Total

Each Module

Bonnet Cap. (1000 Btuh) Total

Stage 1/Stoge 1 ± 2

1 . 1075

1 ... 1140

56 (1-phase)

56 (3-phase)

I 1

1140 . 56 (3-ph)

No. ... Size (in.)

2 ... 15x15

2 . 15x15

2

. 15x15

2 . 15x15

3 ... 15x9

3 . 15x9

Cfm (Norn)

6000

8000

10,000

10,000

12,000

12,000

Motor Hp ... Rpm Std

5 . . 1725

7/2

... 1725

10 ... 1725

10 ... 1725

15 ... 1725

15 ... 1725

Opt

-

-

-

-

20 ... 1725

20 ... 1725

Fan Pulley

Outside Diameter (in.)

10.6

10.6

8 0

8 0

8 0

8.0

Bore (in..)

Р/!б

P

/16

1“/б

1‘Мб

Fan Belt No. ... Size w/Std Mtr

1 3V630

1 ... 3V630

2 ... 3VS60

2 . 3V560

2 3V630

2 ... 3V630

w/Opt Mtr

-

-

-

-

3 . 3V670

3 . . 3V670

Motor Pulley A

Factory Instai led

Outside Diam (in.) w/Std Mtr

5.3

6.0

5 0

'5 0

5 0

5.0

w/Opt Mtr

_

-

-

-

6.0

6.0

Bore (in.)

iVe

1%

1

%

1%

1%

1%

Resulting Fan Rpm w/Std Mtr

880

995

1095

1095

1095

1095

w/Opt Mtr

-

-

-

-

1320

1320

Motor Pulley B

Shippec With Unit

Outside Diam (in.) w/Std Mtr

6.0

6 9

5.6

5 6

5 6

5.6

w/Opt Mtr

—

-

6.5

6.5

Resulting Fan Rpm w/Std Mtr

995

1145

1230

1230

1230

1230

w/Opt Mtr

-

-

1425

1 1425

2-Stage Furnace Assembly in Each Zone Module

HEATING SECTION (SOME ELEC)

HEATING SECTION (SOME, GLY.)

Max allowable inlet temperature

Max allowable flow, each coil

Solution mixture

Max allowable working pressure

Total internol volume (gals)

PRESSURE SWITCHES

,

_

Cutout

Low-Pressure

r. ^ .

Cut-in

High-Pressure

^ul^n

Indoor Air Flow Switch (AFS 1)

Factory Setting (cfm)

Adjustment Range (cfm)

INDOOR AIR FILTERS

Std No. ... Size (in.)

High Efficiency (optional)

No. ... Size (in.)

Roll Media (optionol)

240-480

60

360

22.5/45.0

240-480

60

360

22.5/45.0

25 F to 55 F at 0 75 in. v^g ESP

300-600

I

300-600

I

360-720

60

60

60

450

450

540

22.5/45.0

I

22.5/45.0

j

22.5/45.0

360-720

60

540

22.5/45.0

See Electrical Data Table for Electric Heat Data

2.61

2.61

1 Heating Coil in each Zone Module

ZOO F

6 gpm

20% glycol

30 psig

3.15

]

3.15

1

3 76

3.76

29 ± 5 psig

39 ± 5 psig

400 ± 5 psig

300 ± 5 psig

6000

4000-6000

9000

6000-9000

12 ... 20x25x2

Same but with 36.5% efficiency (NBS Dust Spot Test)

65 ft of 2-in. media

О