Motor support channel – Carrier 50BA User Manual

Page 9

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

#

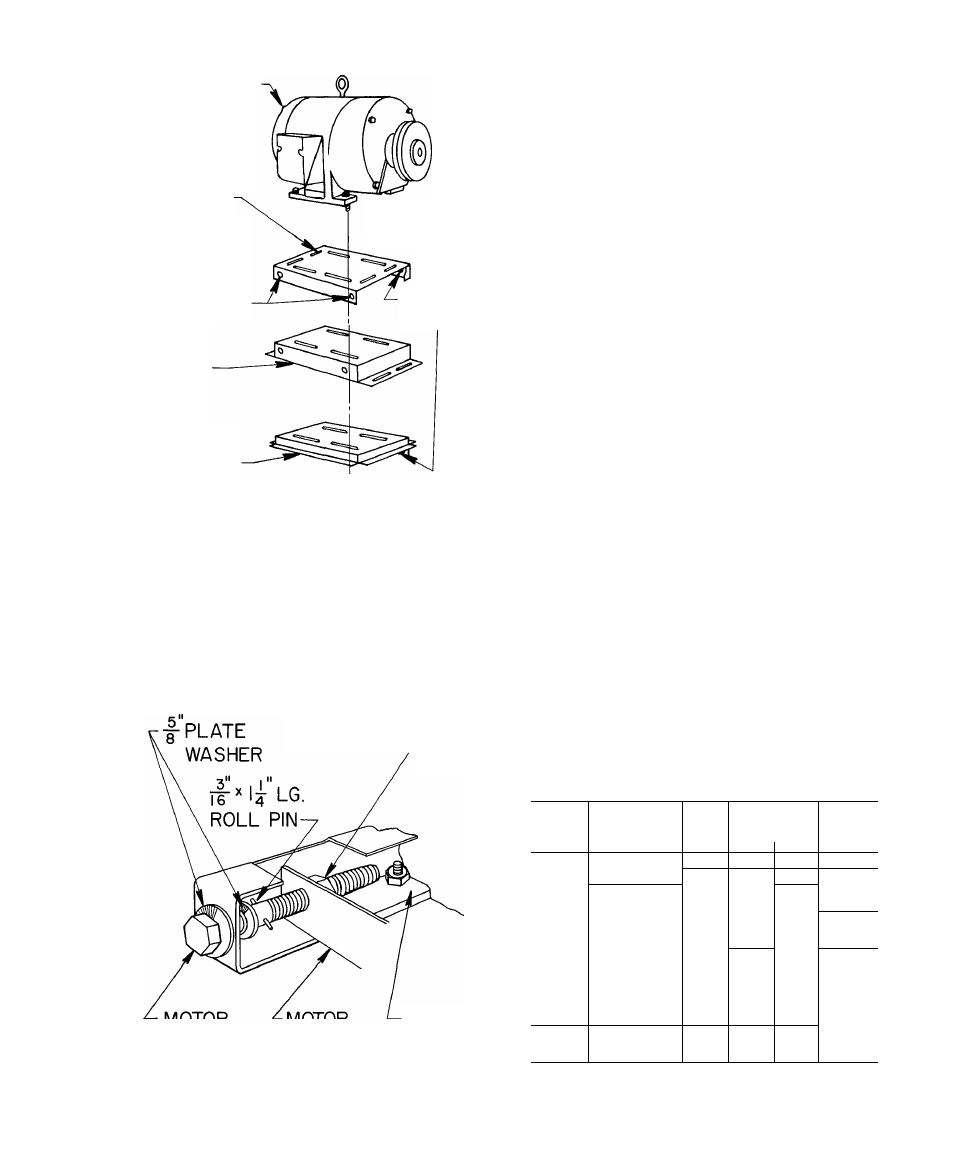

MOUNTING

PLATES

WELD

NUT

FAN MOTOR

50BA,BB

028,034

HOLES

FOR

ADJUSTING

SCREWS

50BA,

BB044

50BA,BB

054,064

Fig. 9 — Motor Mounting

NOTE: On 044 units, motor mounting plate and

channels are factory installed within fan section. No

angle frame plates or fasteners are necessary. In this

position, motor is on right side of fan section.

5. Adjust the following per Installation Step 8:

a. Fan wheel alignment.

b. Shaft alignment.

c. Pulleys.

d. Fan belts.

SUPPORT CHANNEL

WELD NUT-

MOTOR

ADJUSTING

SCREW

MOTOR

SUPPORT

ANGLE

Fig. 10 — Assembled Fan Motor

Adjusting Screw

MOTOR

SUPPORT

CHANNEL

6. Replace panels as follows:

a. Rear coil-section panels, front and rear fan-

section panels.

b. All end panels.

Step 7 — Install fan motor.

This step applies to unit Sizes 50BA,BB028, 034,

054 and 064. Install items after fan-section frame

has'been placed in position on coil section.

NOTE: Place plywood over evaporator coil to pre

vent damage while installing motor and mounts.

To install motor:

1. Fasten motor mounting angle bracket to fan sec

tion. Use Fig. 4 or 5 for position reference and

Fig. 6, 7 and 8 for assembly guidance. Be sure

that lips of angle brackets are around fan-section

frame and that slots for motor mounting plate

face each other.

On Sizes 50BA,BB054 and 064, align bearing

support bracket holes with holes in motor

mounting bracket. Fasten with bolts, flat

washers, lock washers and nuts as shown in

Fig. 8.

2. Position motor on motor plate (Fig. 9) and fasten

with fasteners provided.

3. Fift motor-plate assembly and slide into motor

mounting angles as shown in Fig. 6. Plate fits into

angle slots. On vertical mounts, the motor-frame

assembly may be lowered to the bottom of the

support angle channels.

4. Assemble and install motor adjusting screws as

shown in Fig. 10. Drive roll pins into screws to

prevent screws from backing out during motor

position adjustment.

5. Adjust motor position. Fasten motor mounting

plate to mounting angles.

Table 2 — Alternate Fan Motors and Drives

UNIT

50BA,

BB

NEMA

FRAME

SIZE*

CENTER LINE

FAfVI

HP

DIST>

___ (ir

XNCE

D..„„

SHAFT

DIAM

Max

Min

(in )

004

56

3/4

17.5

15.7

1/2

006

56

1

17 1

15.4

5/8

008,

184, 56, 145T

2

102

6 8

3/4

012

182T, 213

3

102

6 8

016,

024

184, 56, 145T

2

11 8

94

213, 182T

3

11 8

8 4

1

184T, 215

5

11.8

8.4

182T, 213

3

34 4

28 8

028,

184T, 215

5

34 4

28 8

1-3/16

034

254U, 213T

7-1/2

33 3

29 8

256U, 21 5T

10

33 3

29 8

044

213T

21 5T

7-1/2

10

14 3

14.3

10 1

10.1

1-7/16

054,

064

21 3T

7-1/2

33 5

29 0

21 5T

10

33 5

29 0

1-7/16

254T

15

33.5

29.0

•Range of motor sizes unit will accept

NOTE Motors and drives other than those furnished with unit

must be purchased locally