Carrier 50BA User Manual

Page 21

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

«

->NOTE: Water regulating valve (water-cooled

condenser)

or

condenser

airflow

(air-cooled

condenser) must he properly set before checking

system charge.

UNIT SIZE 50BA004 AND 006 - Units are

shipped with full operating charge. If recharging is

necessary:

1

.

2

.

3.

4.

6

.

Insert thermometer bulb in insulating rubber

sleeve on liquid line near filter-drier.

Add pressure gage to discharge line near

compressor.

After unit conditions have stabilized, read head

pressure on discharge line gage.

From standard Pressure-Temperature chart for

R-22, find equivalent saturated condensing

temperature.

Read liquid line temperature on thermometer;

then subtract from saturated condensing tem

perature. The difference equals subcooling

temperature.

Compare the subcooling temperature with the

normal temperature listed in the following table.

If subcooling is low, add charge; if high, remove

charge.

UNIT

50BВ0ПП4

50BA006

^B^COOLING*

25

22 + 2 F

^Saturated condensing temperature at compressor minus

liquid line temperature

EXAMPLE;

Head pressure (from gage)

= 220 psig

Saturated cond temp (from chart) =

108 F

Liquid line temp (from thermometer) =

96 F

Subcooling (by subtraction)

=

12 F

(add charge)

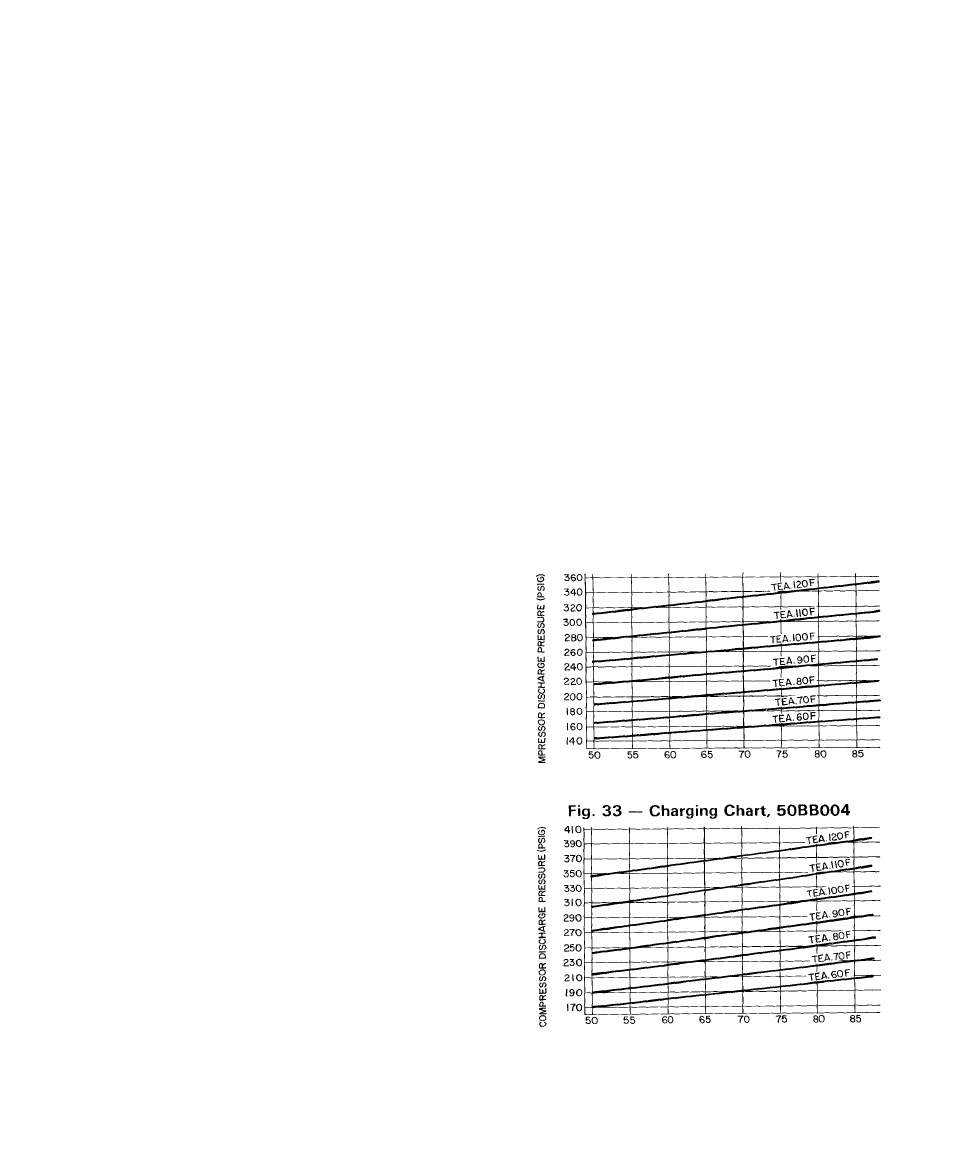

UNIT SIZE 50BB004 AND 006 — Units are

shipped with a holding charge only. To charge;

1. Open suction and discharge line service valves.

2. Blow holding charge, evacuate and leakiest

system.

3. Using standard refrigerant charging techniques

and the charts which follow (Fig. 33 and 34), add

refrigerant as required to maintain proper

operating conditions.

UNIT SIZE 50BA008 THRU 064 — These units,

with water-cooled condensers, are shipped with a

full operating charge. If recharging is necessary

(complete charge lost), weigh in amount of refrig

erant indicated on unit nameplate and Table 1.

If unit has partial charge, it may be charged with

sight glass using standard charging techniques. Ad

just the water regulating valve to maintain proper

saturated condensing temperature (168 - 226 psig).

Refrigerant can be added to 50BA008 and 012

units after sight glass is cleared to take advantage

of the condenser subcooling feature. Add refrigerant

as follows;

50BA008 — 2.6 lb

50BA0I2 — 0.5 lb

On 50BA064 units, adding liquid refrigerant to

the level of condenser test cock will provide 12 to

15 F subcooling.

UNIT SIZE 50BB008 THRU 064 — These units,

with remote air-cooled condensers, are shipped with

a holding charge only. To charge;

1. Open suction and discharge line service valves.

2. Blow holding charge, evacuate and leakiest

system.

3. Add sufficient refrigerant vapor to permit con

tinuous operation after starting unit.

Start unit per Start-Up Section; then, using

standard charging techniques, add refrigerant as

required

to

maintain

normal

operating

conditions.

Use charging chart supplied with condenser. If

information is not available, block off enough of

condenser coil to maintain 220 psig discharge

pressure and charge to a clear sight glass.

Return-Air Grille Removal

(50BA,BB004-012) —

Loosen 2 screws visible thru grille at upper and

lower corner of one side. Slide grille side frame off

unit; then slide grille sideways and pull it away from

unit. To reassemble, reverse procedure.

4.

TEA

COMPRESSOR SUCTION PRESSURE (PSIG)

Temperature, Entering Air

COMPRESSOR SUCTION PRESSURE (PSIG)

TEA — Temperature, Entering Air

Fig. 34 — Charging Chart, 50BB006

21