Water piping – Carrier 50BA User Manual

Page 14

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

ALL 50BB (AIR-COOLED) UNITS — Install air

cooled condenser in accordance with the installation

instructions provided with condenser. Connection

locations for liquid and hot gas service lines are

shown in Fig. 16. Recommended line sizes are given

in Table 5. Refer to Carrier System Design Manual,

Part 3, for standard refrigerant piping techniques.

Condenserless (50BB) units are shipped with a

holding charge. After refrigerant connections are

made, evacuate, leak test and charge system as

REFRIGERANT IN

50BA004

1/2-in. FPT Conn,

50BA006

3/4-in. FPT Conn.

50BA008.012

1 -in FPT Conn

WATER

OUT

WATER

IN

-—c

CONNECT TO

LIQUID SERVICE

VALVE GAGE PORT'

WATER / /'WATER

SHUTOFF^ ^ REGULATING

VALVE

VALVE

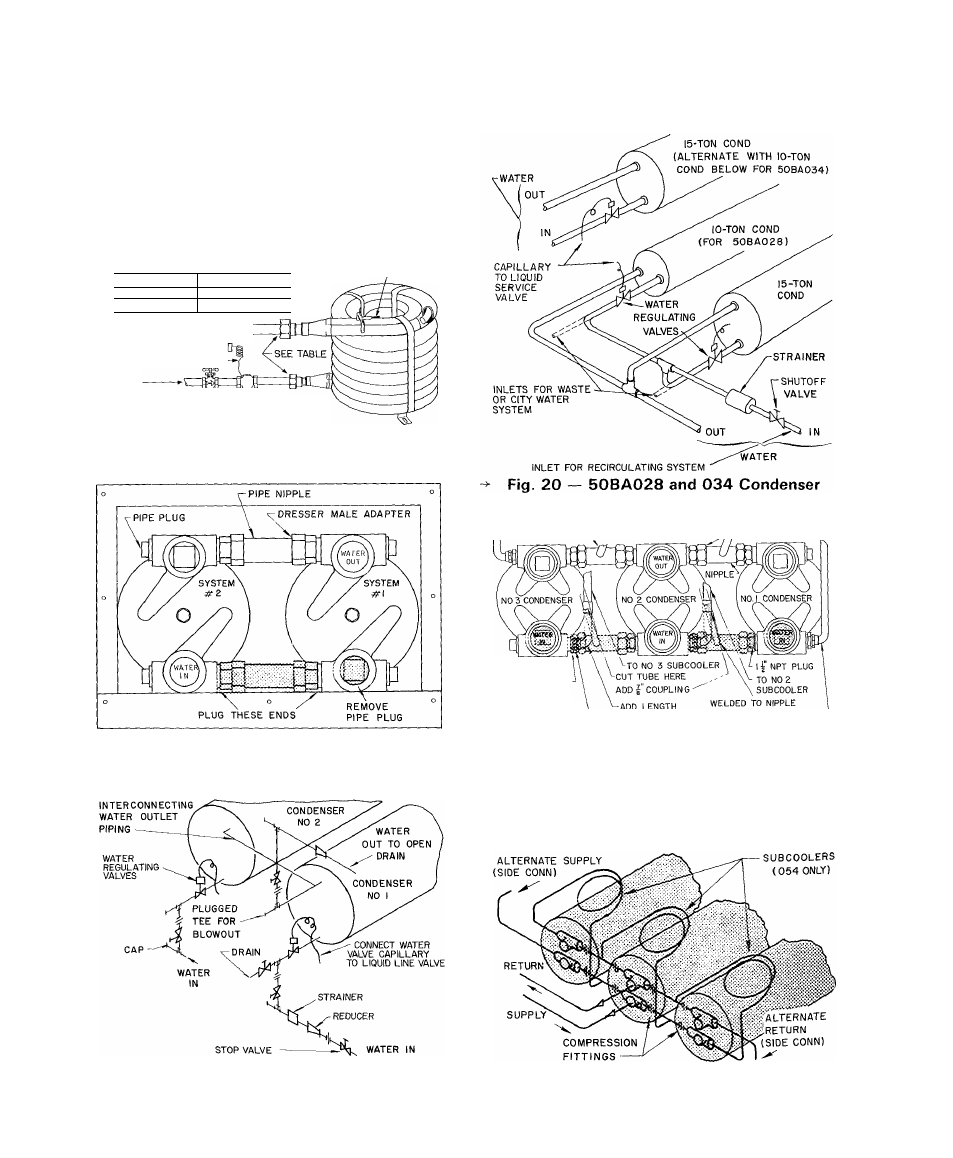

Fig. 17 — Condenser Water Piping

(50BA004-012)

REMOVE SHADED FITTINGS

Fig. 18 — 50BA024 Condenser City Water

Piping Conversion

Fig. 19 — 50BA024 Typical Waste or

City Water Piping

described in the Service section entitled. Charging

the System. Unit refrigerant operating charge is

listed in Table 1.

Water Piping

/-FROM N0.3

SUBCOOLER

^FROM N0 2

\SUBCOOLER

’’DRESSER”

a

FROM NO.I

adaptersn

/

v

subcooler

T'

npt

to

}"

npt

bushing

COUPLING

|"

n

PT-J"

t

UBE---------------- ' O

f

T

u

BE’

to

no

I

subcooler

(EXISTING)'

A Remove shaded fittings

-^NOTE 50BA044 units same less subcoolers

1 Use one outlet for water discharge

2 Remove interconnecting nipples and "dresser” adapters on

inlet side of condensers

3 Remove 3-in plugs from no 1 and 3 condenser inlet headers

Fig. 21 — Field Conversion to City or

Waste Water System (50BA044 and 054)

Fig. 22 — Recirculating Water System Piping

(50BA044 and 054)

i

\ A