Table 4 — maximum water-side working pressure – Carrier 50BA User Manual

Page 12

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

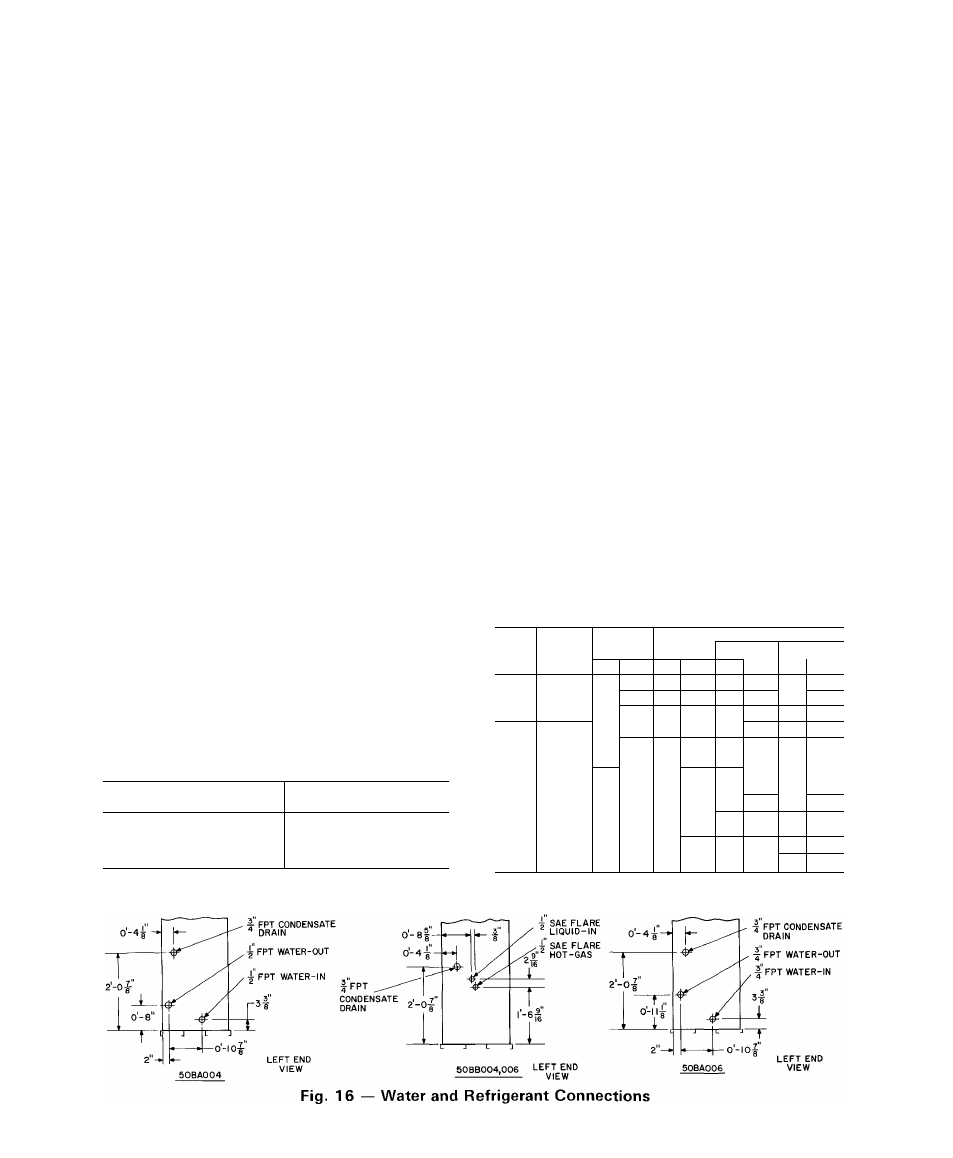

WATER-COOLED

UNITS,

SIZE

50BA004

THRU 012 — Connect condenser water supply and

return lines as indicated in Fig. 16 and 17. When

connecting water lines, hold the condenser inlet and

outlet stubs firmly with a wrench at the FPT hex

fitting to prevent twisting. Do not use water lines

smaller than connection sizes shown in Fig. 17.

Observe all applicable plumbing and sanitary codes.

To assemble Carrier Compatible Fittings:

1. Cut tubing to length with tube cutter and remove

burrs.

2. Mark required insertion depth on tube (1-1/4 in.

for 5/8- and 3/4-in. OD tubing).

3. Remove plug from fitting and loosen nut one

turn.

4. Position and insert tube into fitting. Bottom

tube past depth mark.

5. Leave nuts on condenser end of tubing. Loosen

and purge one line at a time, using holding

charge in base unit.

6. Tighten nuts to stop on unit fitting collar.

7. Open all service valves.

Make sweat connections as follows:

1. Clean tube; then remove plug and nut from

fitting.

2. Remove O-ring from inside fitting with bent pin.

3. Wrap entire valve with wet rag.

4. Bottom tube in fitting and apply low temperature

solder, such as Allstate 430.

If specified, install field-supplied water-regulating

valve in water supply line outside cabinet as

follows:

1. Route the regulating valve capillary with its flare

nut to the fitting on refrigerant liquid line (Fig. 2),

using any convenient unused opening on side of

unit. Use a grommet in unit panel to prevent

chafing of capillary.

Table 4 — Maximum Water-Side

Working Pressure

UNIT SIZE 50BA

MAXIMUM WORKING

PRESSURE

004,006,008,012

450 psig

016

550 psig

024,028,034,044,054,

150 psig*

064

250 psig

2. Remove cap from liquid line fitting.

3. Remove cotter pin taped to liquid line near

fitting. Insert pin, split end first, into water

regulating valve flare nut.

4. Connect flare nut to fitting. Round end of cotter

pin will depress core of fitting. The opened

fitting allows refrigerant pressure to act on water

regulating valve. Tighten flare nut to prevent

leakage.

The fitting automatically seals (closes) when flare

nut is removed; a slight amount of refrigerant is lost

each time, however. Do not lose cotter pin.

WATER-COOLED UNITS, SIZE 016 THRU 064

— Connect condenser water supply and return lines

as indicated in Fig. 16. Unit Size 50BA024, 044, 054

and 064 require field modification to condenser

piping when used on city or waste water. Refer to

Fig. 18, 21 and 24.

Install a water regulating valve on the inlet of each

condenser with any size unit used on waste or city

water (Fig. 19,20,22,23 and 24). Connect regulating

valve capillary to a back-seated liquid service valve.

Arrow on valve body must point in direction of

liquid flow. After connecting capillary, open

regulating valve one turn from back-seated position.

Adjust valve to maintain proper condensing

temperature.

Install a full size gate valve and strainer in water

supply line. Valve and strainer must be accessible.

See Table 4.

Table 5 — Recommended Line Sizes (in.)

(Condenserless Models)

*550 psig if factory-installed dresser adapters are removed and

field-fabricated manifold is installed

UNIT

50BB

CONN

LENGTH OF LINE

SYSTEM

SIZES*

20

40

60-80

L

HG

L

HG

L

HG

L

HG

004

—

1/2

1/2

1/2

1/2

1/2

5/8

1/2

7/8

006

—

1/2

1/2

1/2

7/8^

1/2

7/8

5/8

7/8

008

—

1/2

7/8

1/2

7/8

1/2

7/8

1/2

7/8

012

-

5/8

7/8

5/8

7/8

5/8

1-1/8

3/4

1-1/8

016

—

5/8

1-1/8

5/8

1-1/8

7/8

1-1/8

7/8

1-3/8

024

1 & 2

5/8

7/8

5/8

7/8

5/8

ï-i/8

7/8

1-1/8

028

1

5/8

1-1/8

5/8

1-1/8

7/8

1-1/8

7/8

1-3/8

2

5/8

7/8

5/8

7/8

5/8

1-1/8

7/8

1-1/8

034

1 & 2

5/8

1-1/8

5/8

1-1/8

7/8

1-1/8

7/8

1-3/8

044

1 & 2

5/8

1-1/8

5/8

1-1/8

7/8

1-1/8

7/8

1-3/8

3

5/8

7/8

5/8

7/8

5/8

1-1/8

7/8

1-1/8

054

1,2,3

5/8

1-1/8

5/8

1-1/8

7/8

1-1/8

7/8

1-3/8

064

1 & 2

7/8

1-3/8

7/8

1-3/8

7/8

1-5/8

7/8

1-5/8

HG — Hot Gas Line (OD

L — Liquid Line (OD in

in )

)

*Sweat connections

12