Table 1 — physical data, Step 3 — provide unit support, Step 4 — rig and place unit – Carrier 50BA User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

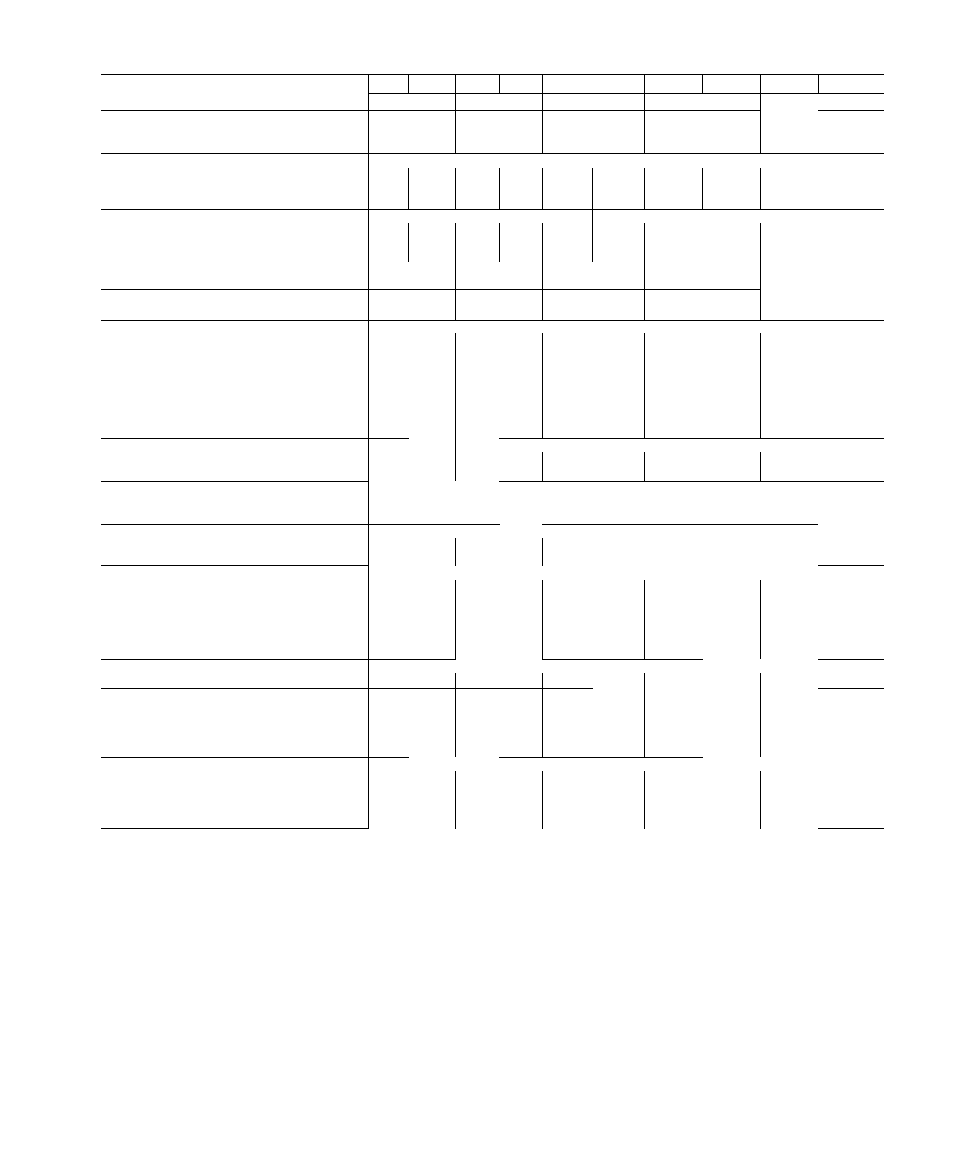

Table 1 — Physical Data

MODEL 50

BA

BB

BA

BB

BA

BB

BA

BB

BA

BB

004

006

008

012

016

OPERATING WEIGHT (lbs)

Base Unit

390

330

427

360

770

710

950

890

1414

1221

Discharge Plenum

25

25

140

140

140

OPERATING CHARGE (lbs)

Refrigerant 22

System 1

3 5

2

46

2 5

10

7

10

8

24

15

System 2

—

—

—

__

—

—

—

—

—

— -

System 3

—

—

—

—

—

—

—

—

-

COMPRESSOR — TYPE 06

Welded Hermetic, 3450 Rpm

Serviceable Hermetic, 1750 Rpm

System 1

M34

M34

P53

P67

P77

DA818

DB724

DB824

DD337

DD537

System 2

—

—

—

—

—

—

—

—

System 3

—

—

—

__

—

—

—

—

No of Unloading Cylinders

0

0

0

2

2

No of Capacity Steps

1

1

2

2

CONDENSER (BA Only)

No. . Type

1

TT

1

TT

1

TT

1

TT

1

SC

INDOOR FAN

Adjustable, Belt-Driven Centrifugal; 1750 Rpm Motor

Nominal Cfm

1200

2000

3000

4000

6000

Standard Fan Speed Range (Rpm)

512-782

647-915

495-700

600-850

568-720

Maximum Allowable Rpm

1100

1100

1100

1100

1100

No. of Belts . Fan Pulley PD (in )

1

64

1

64

1

8 5

1

70

1

11 4

Motor Pulley PDR (in )

1 9-2 9

2 4-3 4

2 4-3 4

2 4-3 4

3 7-4 7

Nom Hp Std...Frame Size

1/3 48

3/4 56

1

56

2

45T

2

145T

Alt...Frame Size

3/4 56

1

56

2

145T

3 182T

3

182T

Alt.. Frame Size

3

182T

5

184T

INDOOR COIL

Copper Tubes, Aluminum Fins

No of Rows . Fins/in

2

13 9

3

13 9

3

12 1

3

12 1

3

106

Total Face Area (sq ft)

50

50

7 3

8 5

16 9

RETURN AIR FILTERS

Factory-Supplied Throwaway Type

4 16x20x1

3 16x25x2

No. ...Size (in.)

2 16x25x1

....... i.......

(See Note 4)

3 20x25x2

CONDENSER CONNECTIONS (BA Only)

Size (in ) . Type

Water Inlet — Manifolded

1/2

FPT

3/4

FPT

1

FPT

1

FPT

2

FPT

Water Outlet — Manifolded

1/2

FPT

3/4

FPT

1

FPT

.... .J...

FPT

FPT

REFRIGERANT CONNECTIONS (BB Only)

Size (in.)...Type

„ ^ - Hot Gas Line

1/2 FI

1/2 FI

3/4

ODF

3/4

ODF

1-1/8 ODM

System 1 Liquid Line

1/2 FI

1/2 FI

5/8

ODF

5/8

ODF

5/8

ODM

_ _ Hot Gas Line

_

System 2 Liquid Line

—

_ ^ _ Hot Gas Line

_

—

Systems Liquid Line

—

CONDENSATE CONNECTION

Size (in ) Type

Condensate Drain

3/4

FPT

3/4

FPT

3/4 FPT

3/4

FPT

1

FPT

ACCESSORY HEATING COIL

Rows ..Fins/in

1

1~5

1

1 5

2

14

2

14

2

11 3

Hot Water

t

, r-

a

/

Total Face Area (sq ft)

5 0

50

60

60

15 7

„ Rows...Fins/in

—

—

1

14

1

14

1

14

Total Face Area (sq ft)

—

—

6 9

6 9

144

HEATING COILS CONNECTIONS

No

Size (in.) MPT

Inlet

1

7/8

1

7/8

1

1-1/4

1

1-1/4

2

1-1/2

Hot Water

r\ ^

Outlet

1

7/8

1

7/8

1

1-1/4

1

1-1/4

2

1-1/2

1

7/8

1

7/8

1

1-1/4

1

1-1/4

1

1-1/4

Outlet

1

7/8

1

7/8

1

1-1/4

1

1-1/4

1

1-1/4

i

Step 3 — Provide unit support.

Refer to Fig. I — Dimensions, and Table 1 —

Physical Data for unit size and weight.

Construct a stand or frame of I-beams or angle

iron that supports unit adequately, if desired. The

floor and floor joists of existing buildings may

require reinforcement; follow applicable codes.

Step 4 — Rig and place unit.

Provide space around unit for service, filter access

and overhead clearance as indicated in Fig. 1.

Move and store unit in upright position.

50BA,BB004 AND 006 — Use rollers under ship

ping rails. Unit may be moved by hand truck on any

side. Do not remove shipping rails until unit is in

final position.

50BA008 THRU 064 — Use slings with spacer under

base skid to prevent panel damage when using hoist.

Raise base skid on blocks and remove bolts. On 028

thru 064 units, unbolt fan section from skid.

Units as shipped are adequately dampened

against vibration. If additional dampening is de

sired, place sponge rubber, rubber mat or fiberglass

roof insulation between floor and base of unit or

install vibration isolators.