Carrier 50BA User Manual

Page 20

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Lubrication

—

Observe

fan

compartment

CAUTION note.

The fan motor bearings are factory lubricated and

will need no lubrication for the first 5 years of opera

tion (3 years at continuous service or excessively

dirty conditions).

Inspect bearings and relubricate or replace as

required. If heating coil is installed, oil bearings

every 6 months. Follow lubrication instructions on

special field-supplied motors.

Fan shaft bearings on 50BA,BB004 thru 034 units

are lubricated for the life of the bearings. The 50BA,

BB044, 054 and 064 units have alemite grease

fittings. Lubricate annually with a good grade of

mixed base grease or lithium base grease with rust

inhibitor. Add grease until air bubbles form under

the seal. Do not overgrease.

Return-Air Filters

— Inspect filters twice monthly

and replace as often as required by operating condi

tions. Filter size and type are listed in Table 1.

If cleanable filters are used, flush them with hot

water or steam or soak them in a mild water solu

tion of soap or detergent. Refer to filter manu

facturer’s instructions as applicable.

Do not operate the unit at any time without

return-air filters in place. For access to filters, refer

to the Service sections entitled. Access Panel

Removal, and Return-Air Grille Removal as

required.

Condensate Drains

— Clean the drain line and

unit drain pan at the start of each cooling season.

Check flow by pouring water into drain. Be sure trap

is filled as shown in Fig. 26 to maintain an air seal.

Evaporator Coil

— Observe fan compartment

CAUTION note at the beginning of the SERVICE

section.

Remove dirt and debris from evaporator coil as

required by condition. Clean coil with a stiff brush,

vacuum cleaner or compressed air. Use a fin comb of

the correct fins/in. spacing (Table 1) when straight

ening mashed or bent coil fins.

Water-Cooled Condenser

(50BA units) may

require cleaning of water-deposited scale.

Condensers are best cleaned with an inhibited

hydrochloric acid solution such as Oakite 32. The

acid can stain hands and clothing, attack concrete

and, without inhibitor, can attack steel. Cover

surroundings to guard against splashing. Vapors

from vent pipe are not harmful, but take care to

prevent liquid from being carried over by the gases.

Warm solution acts more readily but cold

solution is just as effective if applied for a longer

period.

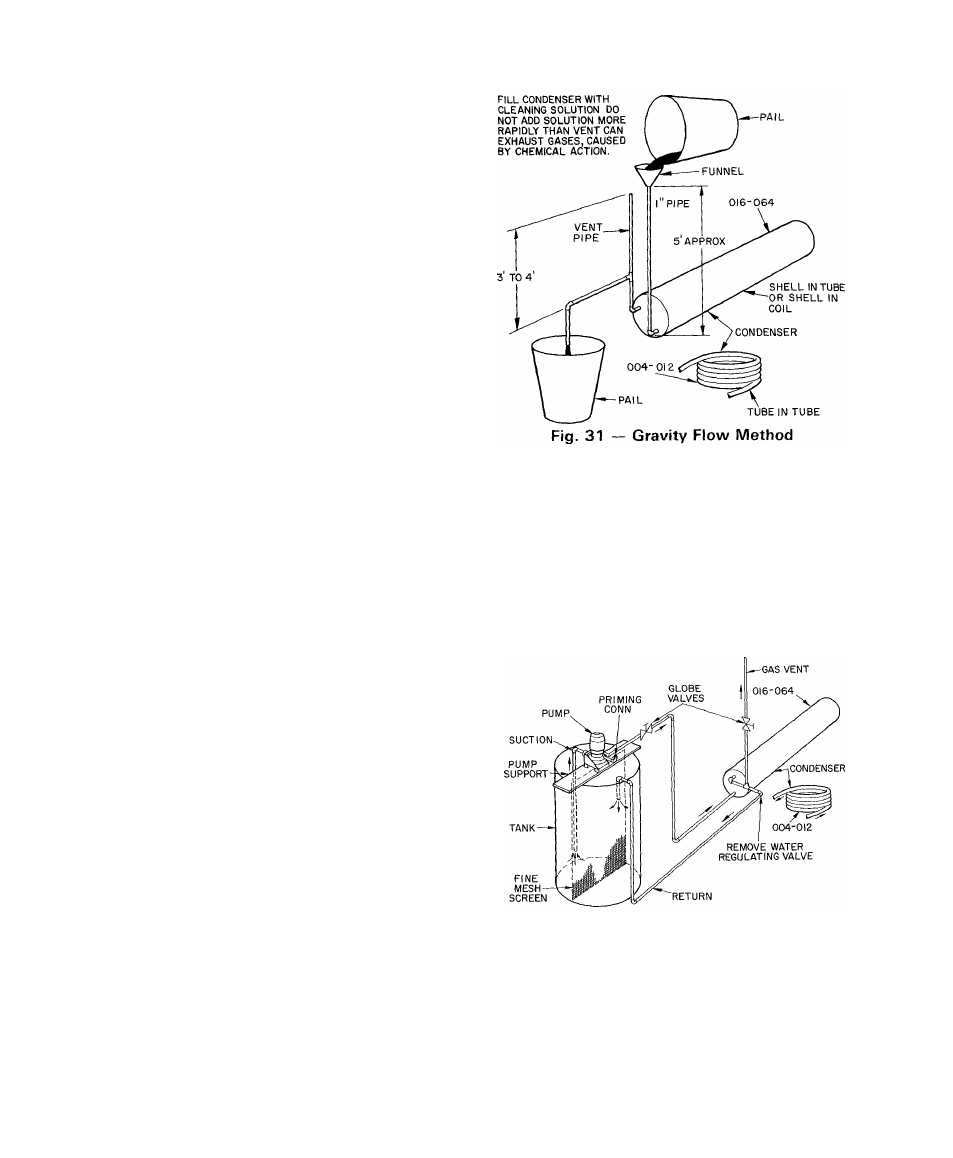

GRAVITY FLOW METHOD (Fig. 31) -- Do not

add solution faster than vent can exhaust the

generated gases.

When condenser is full, allow solution to remain

overnight, then drain condenser and flush with clean

water. Follow acid manufacturer’s instructions.

FORCED CIRCULATION METHOD(Fig. 32) —

Fully open vent pipe when filling condenser. The

vent may be closed when condenser is full and pump

is operating.

Regulate flow to condenser with a supply line

valve. If pump is a nonoverloading type, the valve

may be fully closed while pump is running.

For average scale deposit, allow solution to re

main in condenser overnight. For heavy scale

deposit, allow 24 hours. Drain condenser and flush

with clean water. Follow acid manufacturer’s

instructions.

Fig. 32 — Forced Circulation Method

Air-Cooled Condenser

(50BB units) — Inspect

and clean periodically, depending upon operating

conditions. Follow the service instructions provided

for the make of condenser used.

Charging the System

— On unit Sizes 008 thru

064, sight glasses are provided at inlet of each expan

sion valve. These glasses are used in the field

charging procedure.

i

20