Carrier 50BA User Manual

Page 19

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Table 10 — Factory Set Points (psig)

UNIT

50BA.BB

ACTION

UNLOADER

NO. 1

UNLOADER

NO. 2

012

Load

Unload

69

58

—

016

Load

Unload

69

58

—

064

Load

Unload

77

58

74

55

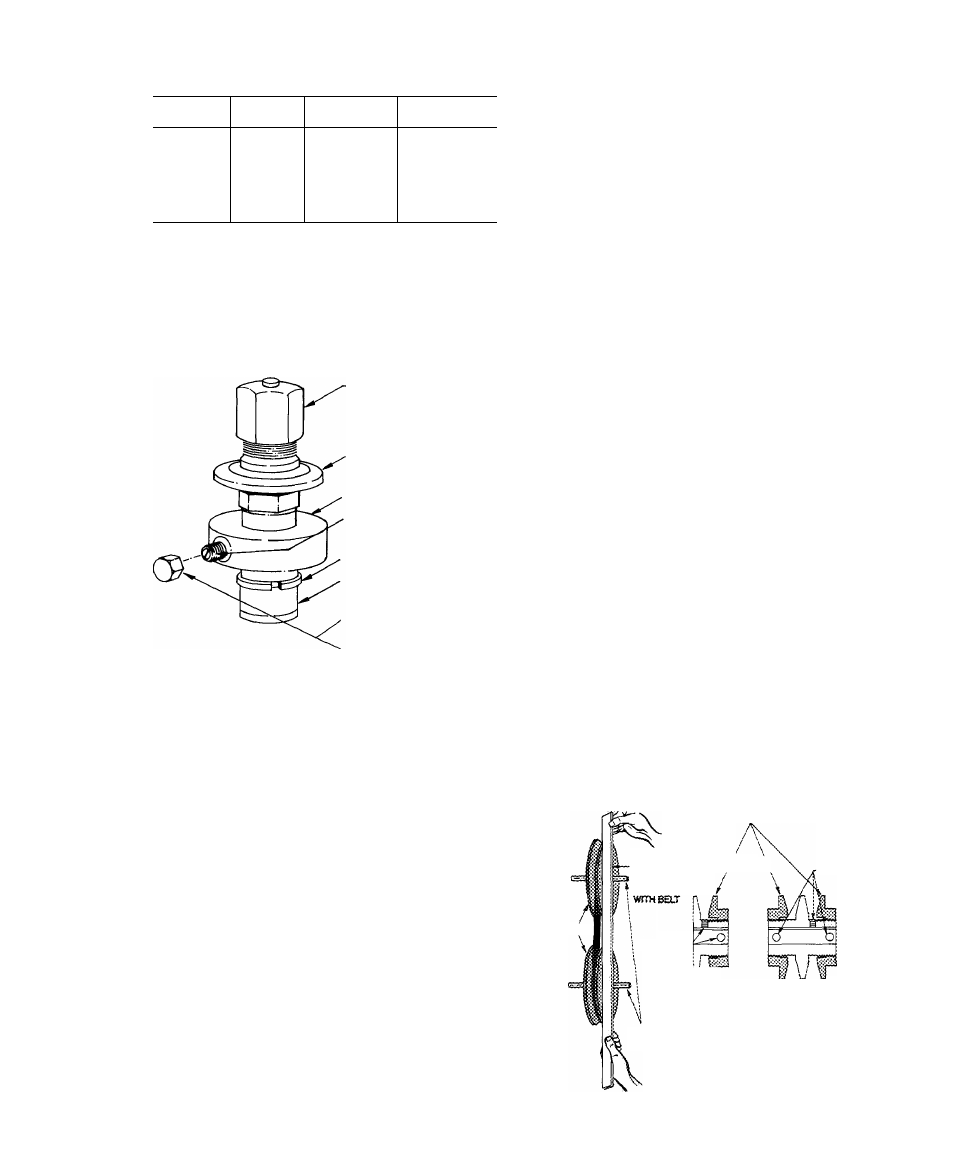

TO REGULATE CONTROL SET POINT

E Turn adjustment nut (Fig. 29) clockwise to its

bottom stop. Set point is now 85 psig.

2. Turn adjustment nut counterclockwise to reach

desired pressure. Each full turn decreases the set

point by 7.5 psig. (Approximately 11-1 /2counter

clockwise turns decreases set point to 0 psig.)

-CONTROL SET POINT

ADJUSTMENT NUT

POWER HEAD

VALVE BODY

PRESSURE DIFFERENTIAL

ADJUSTMENT SCREW

BYPASS RSTON RING

BYPASS PISTON

DIFFERENTIAL SCREW

SEALING CAP

REPLACE CAP TO PREVENT

REFRIGERANT LEAKAGE

Fig. 29 — Capacity Control Valve

TO ADJUST PRESSURE DIFFERENTIAL -

Turn differential adjustment screw (Fig. 29)

counterclockwise to its back-stop position. Differ

ential is now 6 psig.

Then turn screw clockwise to desired differential.

Each full turn increases differential by 1.6 psig.

(Approximately

10

clockwise

turns

increases

differential to 22 psig.)

SERVICE

CAUTION: Before sert'icing fair compartment;

E Sharp edges of ex'aporator coU fms are ex

posed, To prevent arm injury, cover top edge

of evaporator with cardboard strip or a few

layers of heavy tape.

2. To avoid coil damage, ctjver evaporator coil

face with ply^vood or other rigid sheet

tnaterial. If any coil fins are mashed or bent,

straighien with a coil ftn comb of the proper

tooth spacing (see coil fins/in. in Table i).

Check for refrigerant leaks.

Indoor Air Fan Adjustment

— Observe fan com

partment CAUTION note above. The fan motor

pulleys are factory set at the fan speeds listed in

Table 1. Unit Sizes 50BA,BB044,054 and 064 have

fixed pulleys.

TO CHANGE FAN SPEED (004-034)

1. Shot off unit power .supply.

2. Loosen fan belt by loosening fan motor from

mounting bracket. Do not loosen fan motor

mounting bracket from unit.

3. Loosen movable pulley flange setscrew (Fig. 30).

4. Screw movable flange toward fixed flange to

increase fan speed and away from fixed flange to

decrease speed, using values shown in Table 1.

Increasing fan speed increases load on motor. Do

no! exceed maximum allowable fan speed (Table

I) or motor full load amps indicated on motor

nameplate and Table 7.

5. Set movable flange setscrew at nearest flat of

pulley hub and tighten setscrew.

6. Check Pulley Alignment and Belt Tension Ad

justment as described below.

7. Check fan operation. Repeat above procedure

as required.

PULLY ALIGNMENT — Shut off unit power

supply. Loosen fan motor pulley setscrews and

slide fan pulley along fan shaft. Make angular align

ment by loosening motor from mounting bracket.

See Fig. 30.

BELT TENSION ADJUSTMENT - Shut off

unit power supply. Loosen fan motor from

mounting bracket. Do not loosen motor mounting

bracket from unit. Move fan motor up or down until

proper belt tension is achieved (approximately

3/4-in. deflection with 8-lb tension at midpoint of

belt span).

MOVABLE FLANGES (004-034 ONLY)

PULLEYS,

STRAIGHT EDGE /

\

MUST BE

PARALLEL

SETSCREWS

SETSCREWS'

;/ <1

^FIXEO

flanges

^

SINGLE-GROOVE TWO-GROOVE

MOTOR BFAN SHAFTS

MUST BE PARALLEL

Fig. 30 — Indoor Air Fan Pulley Adjustment