Carrier 48KH User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

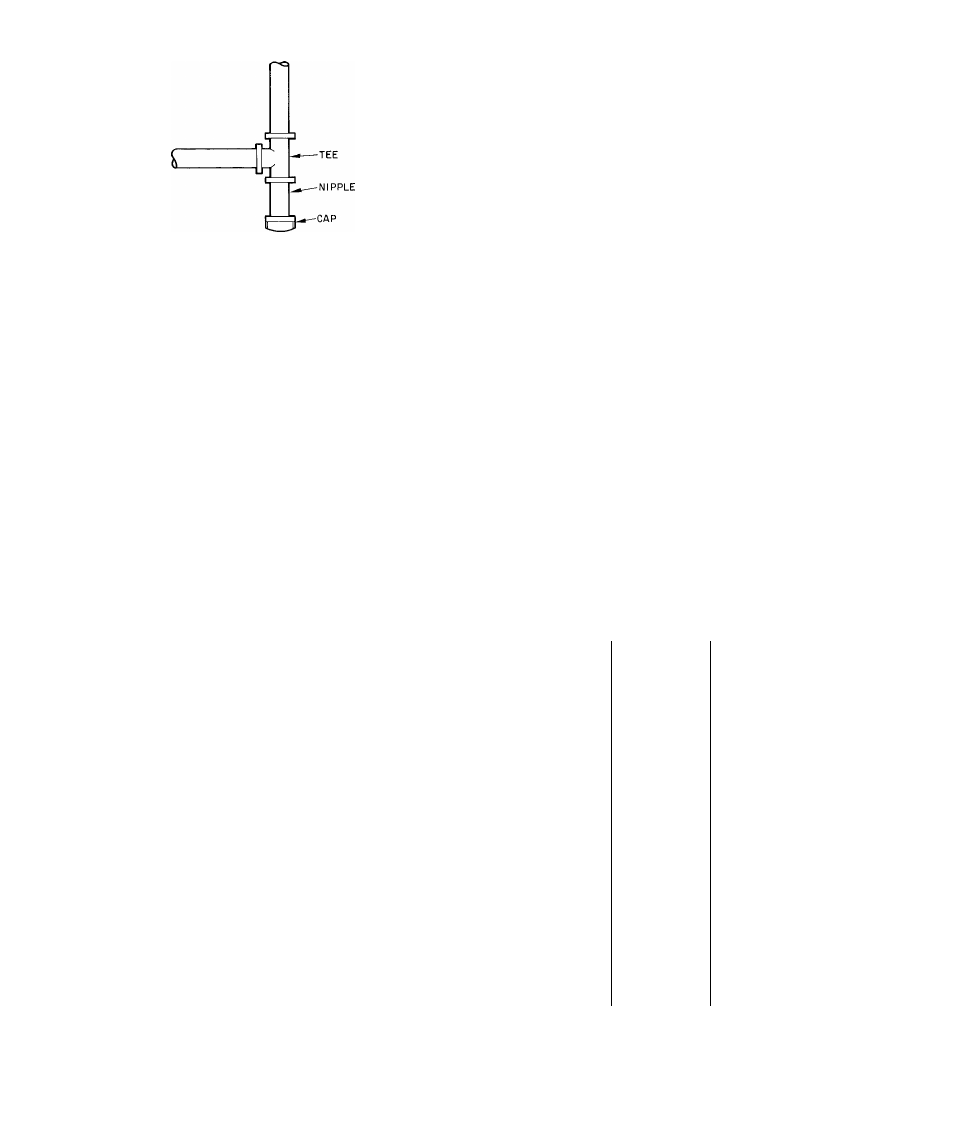

Fig. 7 — Sediment Trap

5.

Install an accessible, external, manual shutoff

valve in gas supply pipe within 6 ft of heating

section. Install a 1/8-in. NPT plugged tapping

that is accessible for test-gage connection imme

diately upstream from gas supply connection to

heating section and downstream from main

manual shutoff valve.

6. Install ground-joint union close to heating sec

tion between gas valve and external manual main

shutoff valve.

7. Pressure-test all gas piping in accordance with

local and national plumbing and gas codes before

connecting piping to unit.

NOTE: When pressure-testing the gas supply

system

after the gas supply piping has been con

nected to the unit gas valve, the supply piping

must be disconnected from the gas valve during

any pressure testing of the piping systems at test

pressure in excess of 0.5 in. wg. When pressure

testing the gas supply piping system at test pres

sures equal to or less than 0.5 in. wg, the unit

heating section must be isolated from the gas

piping system by closing the external main

manual

shutoff

valve

and

slightly

opening

ground-joint union.

CAO'OON; OfisSiabieopciSiiloiìmayoccitr, ps?-

ttcalarly ajtdej

cosditioas» when gas;

aad maììifoìd assentbiy ate foreed o«t of

while cesitiecSsg iaijwopBriy routed»

gas

t-o .gas vidvee Use a bacicap

wcesch wbeti saaktag eosmecisoa to avoid stsais

03R» or dtsiordow of, gas control plpiog,

8. Where permitted by local codes, use an approved

corrugated metal tubing gas connector between

rigid gas piping and gas valve.

WARNING: Never saae a îmtcïi or other o-pen

flaaie when elîeckisg for leaks.

9.

Check for gas leaks at all field-installed and

factory-installed gas lines after all piping connec

tions have been completed. Use soap-and-water

solution (or method specified by local codes and/

or regulations).

Step 3 — Make Duct Connections

— Model

48KH,KL has duct flanges on the supply-and return-

air openings on side of unit. See Fig. 4.

WARNING: The design and installation ofdagt

system mmt he in atx-ordancewttit standards of

Natlonai Fire Protecdon Assoctatioo for tw-

staïiaiton of ncm.~restdencetypeatreoodittoaEiing

and ventilating systems» NFPA Nox9ê; or

residence-type NFPA No. 90 &; aad/ttr h>cai

codes and ordlsaxtces.

Adhere to the following requirements when selec

ting, sizing and installing duct system:

1. Select and size ductwork, supply-air registers and

return-air grilles according to ASHRAE recom

mendations and as presented in Carrier System

Design Manual, Part 2. System airflow must be

within range of temperature rise and external

static pressure shown on unit AGA rating plate.

CAÏJTEON: Whca doct~systcm fasteaiag

holes are drilled into side of Model dSKBXL

mstead of the tmit ddct fiaages, lise extreme

care to avoid panctoriag ood or cod tubes.

2. Use a flexible transition between rigid ductwork

and unit to prevent transmission of vibration.

The transition may be screwed or bolted to duct

flanges. Use suitable gaskets to ensure a weather-

tight and airtight seal.

Table 2 — Filter Sizes (Field Supplied),

Size Sq In.*

STANDARD

CLEANABLE OR

MODEL 48—

DISPOSABLE

HIGH CAPACITY

TYPE

TYPE

KL.018300BE

300

187

KL024300BE

400

257

KH024300BE

400

260

KL030300BE

522

339

KH030300BE

522

339

KL036300BE

576

374

KL036500CE

576

374

KL036600CE

576

374

KH036300BE

583

379

KH036300BF

722

451

KH036500CE

576

374

KH036500CF

694

451

KL042300BE

~

. .. _

43У

KL042500CE

672

437

KH042300BE

672

437

KH042500CE

672

437

KL04830ÒBE

768 ~~

499"

KL048500CE

768

499

KL048600CE

768

499

KH048300BE/BF

768

499

KH048500CE/CF

768

499

KL060300BE

95d

618 ’

KH060300BE/BF

950

618

^Recommended air filter areas shown are based on either the ARI-

rated cooling airflow or the heating airflow at a velocity of 300 fpm

depending on whichever value is larger Air filter pressure drop

should not exceed 0 08 in wgfor unit to produce the rated cooling

performance