Carrier 48KH User Manual

Page 3

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

rooftop

installation

CAUTTONc Whfirc bstaiSng amt

oh

à

rooftop.

When installing a Model48KH,KL end discharge

unit with a field-supplied downflow plenum, a field-

supplied roof-mounting curb must be installed on

and flashed into roof before unit installation. When

installing a Model 48KH,KL end discharge unit

without a downflow plenum, place unit on a level

base that provides proper support. On flat roofs be

sure unit is located at least 4 in. above highest ex

pected water level on roof to prevent flooding.

Consult

local

codes

for

additional

installation

requirements.

GROUND LEVEL INSTALLATION — Place unit

on a solid, level concrete pad that is a minimum

of 4 in. thick and that extends approximately 2 in.

beyond casing on all sides of unit. Do not secure unit

to pad

except when required by local codes.

CLEARANCES — Required minimum operating

and service clearances are shown in Fig. 4 for pro

viding adequate combustion, ventilation and con

denser air.

CAin iON: Do aot restrici

cmdtass&v

asrilo«?,

A» mi

restrbtion at either oHtdoor-'aif inkst

emSfo SHtiace of ifee oa.id.oor

coii)

or fea. dis

charge caa bo dotriateatai to coca^ssor Bfe.

Condenser fan discharges thru top of unit. Ensure

that fan discharge does not recirculate to condenser

coil. Do not locate unit in either a corner or under a

complete overhead obstruction. Minimum clearance

under a partial overhang (such asa typical house roof

overhang) is 3 ft above vent cap. Maximum hori

zontal extension of a partial overhang must not

exceed 4 feet.

Do not locate unit where water, falling ice or snow

from an overhang or roof will damage or flood the

unit. Do not locate unit where grass, shrubs or other

plants will interfere with the airflow either into or

out of unit. Do not install unit on carpeting, tile or

other

combustible

material

other

than

wood

flooring.

CONDENSATE DISPOSAL

NOTE: Be sure condensate water disposal methods

comply with local codes, restrictions and practices.

Models 48KH,KL dispose of condensate water

thru a 3/4-in. MPT drain fitting. See Fig. 4 for

location.

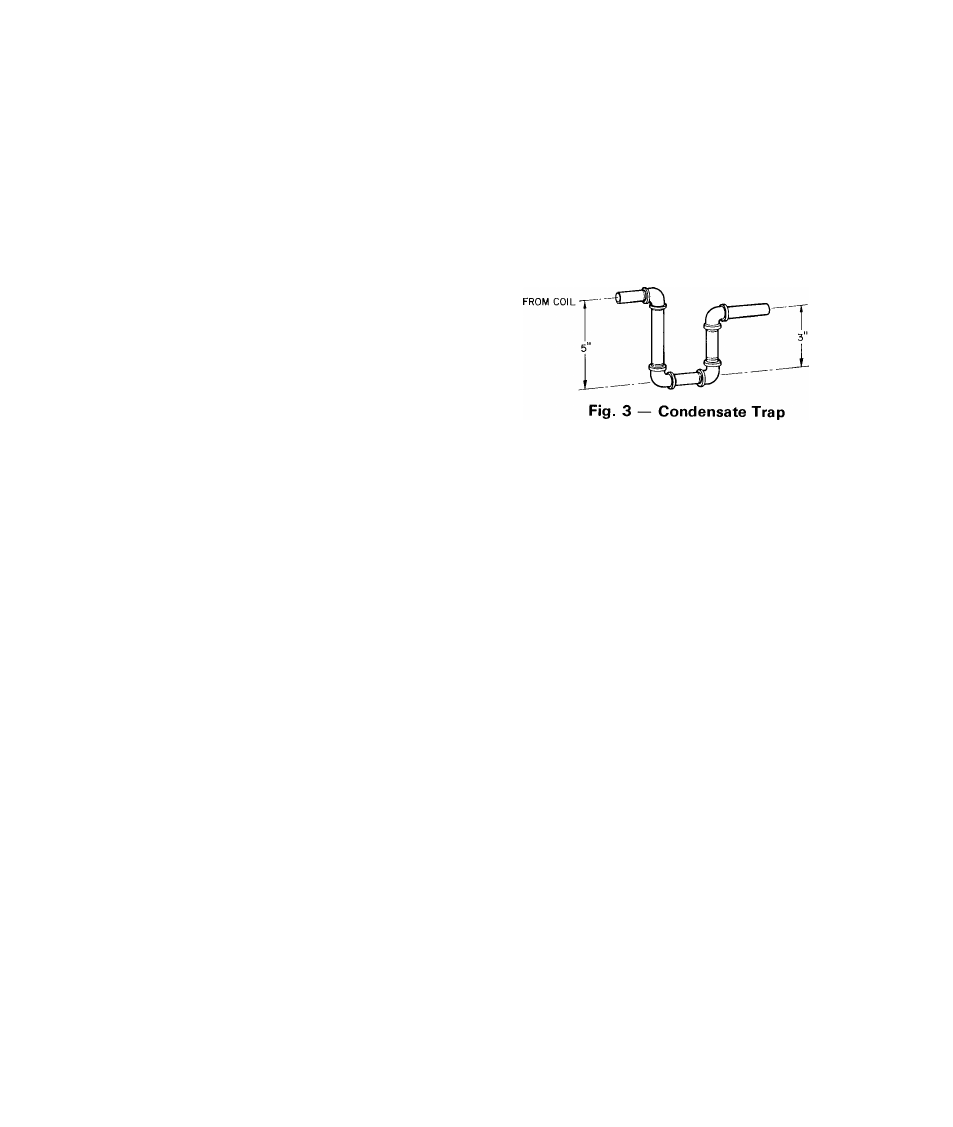

Install a 3-in. trap at the drain fitting to ensure

proper drainage. See Fig. 3. Make sure trap outlet

is at least 2 in. lower than unit drain pan connection

to prevent pan from overflowing. Prime trap with

water.

If installation requires draining the condensate

water away from unit, connect a drain tube using a

minimum of 7/8-in. OD copper tubing, 3/4-in.

galvanized pipe or 7/8-in. plastic pipe.

Do not

undersize the tube. Pitch drain tube downward at a

slope at least 1 in. for every 10 ft of horizontal run.

Be sure to check drain tube for leaks.

Condensate water can be drained directly onto

roof in rooftop installations (where permitted) or

onto a gravel apron in ground level installations.

When using a gravel apron, make sure it slopes away

from the unit.

TO DRAIN

VENTING — The vent cap, combustion air shroud

and flue assembly are shipped in either the blower or

control compartment. Vent screen is taped to blower

housing. Remove access doors to locate assemblies.

See Fig. 4 for door locations.

C-AUTiOKt V

giroper ïeïîttïîg,

fee si-

stalled as Îîî^icated iielovs^.

NOTE: Screw holes in flue assembly and unit top

are positioned to ensure proper orientation when

installed. Refer to Fig. 5 and install vent cap as

follows:

1. Place combustion air shroud over combustion air

opening in unit top, and line up screw holes in

shroud with holes in top. Secure shroud to top,

using screws with rubber washers (provided).

2. Plaee gasket and flue assembly thru hole in com

bustion air shroud, orient screw holes in base of

flue assembly with holes in unit top, and secure

gasket and flue assembly to unit top, using screws

provided.

3. Form flat wire screen (provided) into circular

shape around protruding lip of combustion-air

shroud and bend wire ends thru holes of screen

mesh to secure screen in place. Make sure that no

sharp edges are left exposed.

4. Place vent cap sleeve inside flue assembly. Orient

spring clip of vent cap with slot in assembly. Be

sure clip snaps into slot to secure clip onto

assembly.