If p3ot ials i.® d.o not, Isio – Carrier 48KH User Manual

Page 15

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

#

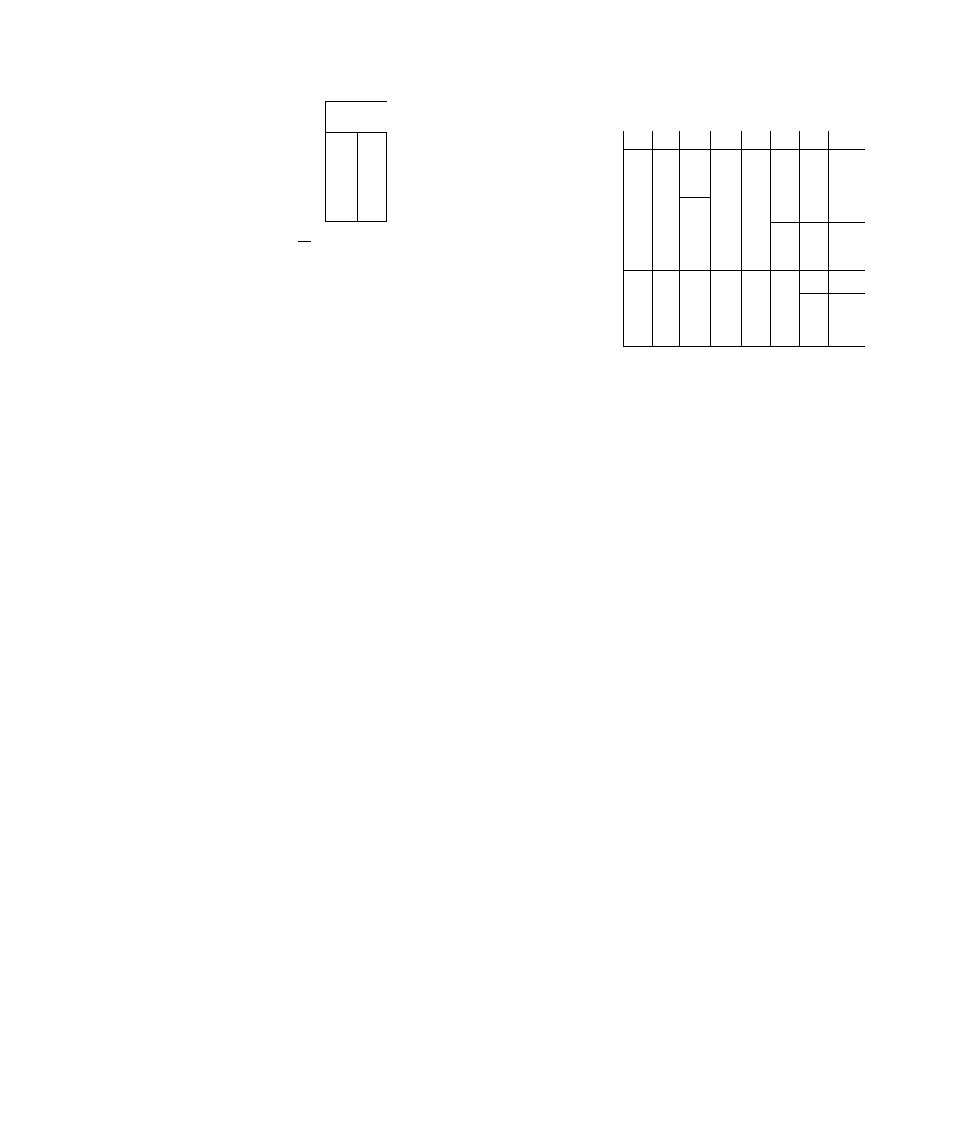

Table 6 — Model 48KH,KL Air Delivery (cfm)*

at Indicated External Static Pressure and Voltage (Cont)

MODEL

48-

UNIT

VOLTS-

PHASE (60 Hz)

208/

230—3

BLOWER

MOTOR

SPEED

Low

Med

High

Low

High

Low

Med

High

COILt

Heat

Cool_

Heat

Cooli

Heat

Cool

Heati

Cool

Heat

Coolt

Heat

Cool

HeatJ

Cool

Heat

Cooli

- -

—

0 0

0 1

1440

1435

1435

1430

1755

1740

1745

1730

1950

1920

1925

1890

EXTERNAL STATIC PRESSURE (in wg)

208V

1425

1420

1725

1710

1880

1850

1415

M10

1700

1680

1840

1810

1400

1395

1665

1645

1795^

1765

1385

1380

1625

1600

1750

1715

•Air delivery values are without air filter Deduct field-supplied air filter pressure drop to

obtain external static pressure available for ducting

tHeating airflow values are with a dry coil Cooling airflow values are with a wet coil

iThese airflow values are at the factory heating and cooling blower motor speed setting

A dash {—) indicates portions of the table that are beyond the blower motor capability or

that are not applicable

1365

1355

1580

1550

1700*

1665

1340

1330

1530

1500

1645

1615

0

8

1305

1290

147(T

1440

1590

1560

230V or 460V

1730

1725

1970

1950

2175*

2130

Î585

1585

2375

2270

Isio

1875

2130

2075

2345

2255

0

1

0

2

0 3

0 4

0 5

0

6

0 7

0

8

1720

1700

1675

1645

1610

1560

1520

1470

1710

1685

1660

1625

1585

1545

1495

1445

1945

1910

1875

1825

1775

1720

1660

1600

1920

1880

1840

1790

1735

1685

1625

1570

2130

2085

2030

1970

1905

1840

1765

1695

2085

2035

1980

1920

1855

1790

1720

1650

1585

1580

1560

1530

1495

-

—

—

1585

1575

1550

1515

1475

—

—

—

2280

2185

2095

2000

1905

—

—

___

2185

2100

2015

1930

1840

-

-

—

1875

1860

1825

1770

1700

—

—

_

1865

1840

1790

1725

1650

—

-

—

2075

2015

1955

1890

1810

_

_

___

2025

1965

1900

1835

1760

—

—

—

2260

2180

2095

2010

1930

_

_

___

2175

21002020

1945

1865

-

-

—

NOTE: Do not operate the unit at a cooling airflow that is less than 350 fpm per each

1 2,000 Btuh of rated cooling capacity Indoor coil icing may occur at airflows below this

point

thermostat

simultaneously

energizes

pilot

valve

(part of gas valve) and pilot igniter. Energized pilot

gas valve permits gas to flow to pilot.

NOTE: Pilot gas valve is a solenoid consisting of a

PICK and a HOLD coil. Both coils must be ener

gized to open pilot gas valve, but only HOLD coil

must be energized to keep valve open.

Energized pilot igniter sends a high-voltage charge

to pilot electrode (part of pilot). Pilot electrode pro

duces a spark that ignites pilot. Elame-sensing

monometal switch in pilot proves presence of pilot

flame. Approximately 40 to 60 seconds after pilot

flame is established, normally closed contacts of

pilot open and normally open contacts close.

Switching of pilot contacts de-energizes pilot igniter

and PICK coil of pilot solenoid. HOLD coil of

pilot solenoid is still energized; therefore, pilot gas

valve remains open and pilot remains lit.

if p3ot ialS i.®

d.o not

a sjafcli or ofeW soarco of

i

Switching of pilot contacts also completes low-

voltage circuit to time-delay heat relay, and terminal

no. 1 of gas valve. After approximately 10 seconds,

heat-motor-operated gas valve opens and permits

gas to flow to burners where gas is ignited by pilot.

Ignited burners heat the heat exchanger.

After built-in time delay, normally open relay

contacts of energized heat relay close, and circuit to

blower motor is completed. Blower motor starts.

Heating cycle remains on until room temperature

rises to a point that is slightly above heating control

setting of room thermostat. At this point, thermostat

heating bulb tilts and breaks circuit between thermo

stat terminals R and W. Gas flow thru gas valve

stops and burner flames go out. Gas flow thru pilot

gas valve also stops and pilot flame goes out.

Time-delay heat relay de-energizes; however, there

is a built-in delay before heat relay contacts open, and

blower continues to move air across heat exchanger

to help optimize heating efficiency. When heat relay

contacts open, circuit to blower motor breaks and

motor stops.

Unit is in a standby condition, waiting for next

call for heat from thermostat.

LIMIT AND PRESSURE SWITCHES — Eurnace

limit switch (see Eig. 10) closes gas valve if leaving-

air temperature exceeds 175 E.

Normally closed limit switch completes control

circuit thru pigtail lead W to gas valve 5 F. See

Fig. 10. Should leaving-air temperature rise to 175 F,

switch opens and W control circuit breaks. Any

interruption in W control circuit instantly closes gas

valve and stops gas flow to burners and pilot. Blower

motor continues to run until time-delay sequence of

heat relay is completed.

When air temperature at limit switch drops to the

low-temperature setting of limit switch, switch

closes and completes W control circuit. Electric-

spark ignition system cycles and unit returns to

normal heating operation.

Pressure switch (see Fig. 10) is required only when

unit operates on LP (propane) gas.

BLOWER

SAFETY

SWITCH

Blower

safety

switch is a temperature-actuated switch connected

parallel with contacts of heat relay. Function of

switch is to activate blower should gas valve fail to

close when thermostat is satisfied. Safety switch is

mounted on blower divider panel. When tempera

ture at safety switch reaches approximately 175 F,

switch closes to start blower. Switch opens when

temperature at switch drops to approximately 116 F.

1 5