Iecfeicai power to . bo «tire to, Caotion: do clm^ hioweshiaotoe' lead, Eone£ercti. Page 17: Table 7 — rated cooling and heating airflows

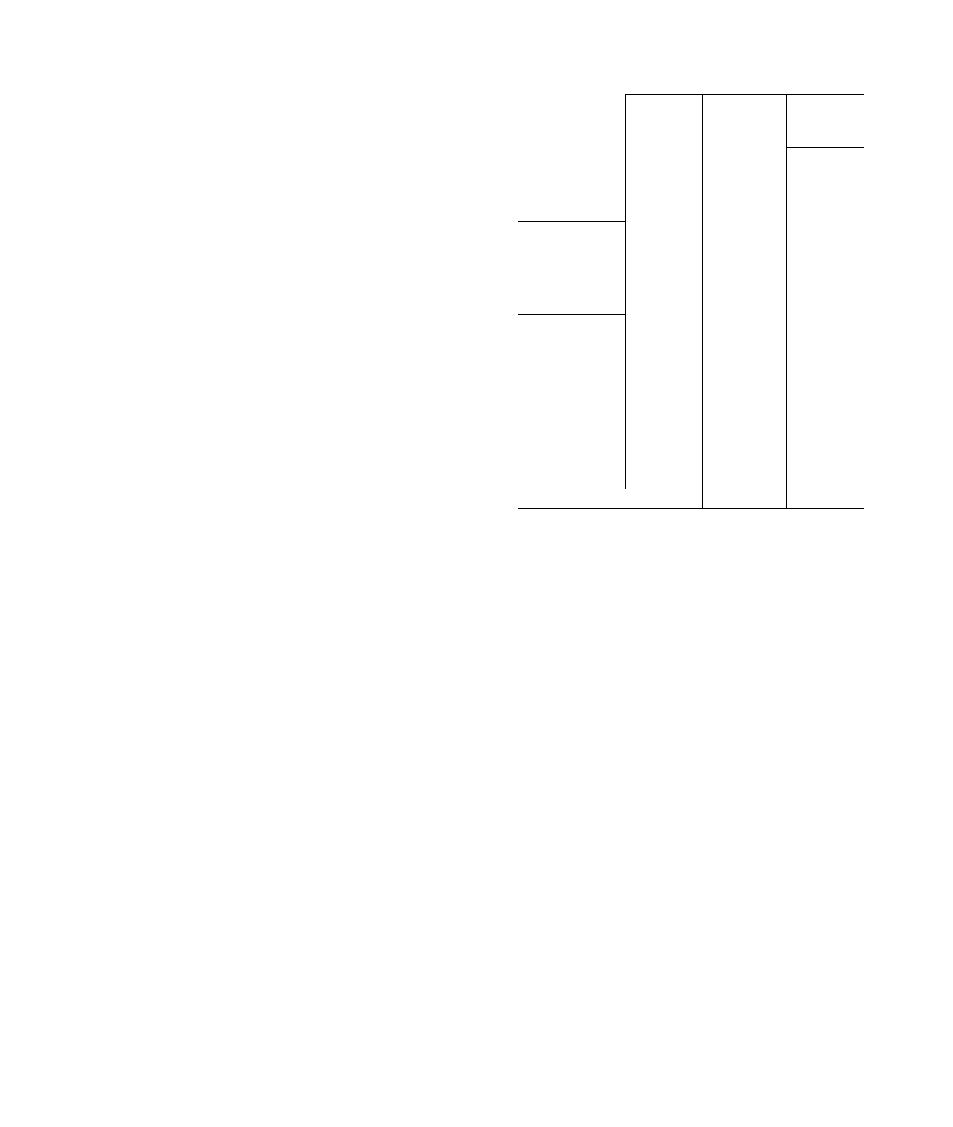

Page 17: Table 7 — rated cooling and heating airflows

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Table 5 shows heating airflow at various tempera

ture rises. Table 6 shows both heating and cooling

airflows at various external static pressures for

Models 48KH,KL direct-drive units. Refer to these

tables to determine airflow for system being in

stalled. See Table? for rated cooling and heating

airflows.

NOTE: Be sure all supply- and return-air grilles are

open, free from obstructions and adjusted properly.

Table 7 — Rated Cooling and Heating Airflows

«•■wvirinrv imv

3£ti^

è

mm

s

«iecfeicai power to

. Bo «tire to

NOTEiWhen operating the 208/230-volt, 3-phase

version of Models 48KH048, 48KL060 and 48KH

060 at 208 volts, lead connections of blower motor

must be changed as indicated on unit wiring label to

ensure proper airflow.

CAOTION: Do

clm^

hiowesHiaotoE' lead

eonE£ercti.

Heating and/or cooling airflow of 208/230-v

direct-drive blower motors can be changed by

changing the lead connections of blower motor.

Motor leads are color-coded as follows:

black — high speed

blue — medium speed

red — low speed

NOTE: Some direct-drive blower motors do not

have lead for medium speed. Factory connections

and available optional connections are shown in

Table 6.

Eor all units, motor lead connected to heat relay

determines heating speed and resulting airflow; and

motor lead connected to cooling relay determines

the cooling speed and resulting airflow. See unit

wiring label.

To change heating and/or cooling speed, connect

appropriate color-coded lead to appropriate relay.

Be sure to properly insulate any unused motor lead.

RATED

EXTERNAL

RATED

MODEL 48—

COOLING

STATIC

HEATING

AIRFLOW

PRESSURE

AIRFLOW

(cfm)*

(in. wg)*

(cfm)

KL018300BE

600

0 10

555

KL024300BE

825

0 10

555

KH024300BE

825

0 10

835

KL030300BE

0 15

465

KH030300BE

1088

0 15

835

KL036300BE

T 200 ”

0.15

" 835......

KL036500CE

1200

0 15

835

KL036600CE

1200

0 15

835

KH036300BE

1215

0 15

1155

KH036300BF

1215

0 15

1445

KH036500CE

1215

0 15

1155

KH036500CF

1200

0 15

1445

KL042300BE

0 15

695

KL042500CE

1400

0 15

695

KH042300BE

1400

0 15

925

KH042500CE

1400

0 15

925

KL048300BE

1600

0 20

925

KL048500CE

1600

0 20

925

KL048600CE

1600

0 20

925

KH048300BE

1600

0 20

1155

KH048300BF

1600

0 20

1445

KH048500CE

1600

0 20

1155

KH048500CF

1600

0 20

1445

KL060300BE

1980

0 20

1155

KH060300BE

1980

0 20

1155

KH060300BF

1980

0 20

1735

*Rated in accordance with ARI Standard 210-81

See Make Wiring Connections, Special Procedures

for 208-v Operation section for proper procedures to

insulate an unused electrical lead.

When installing a 208- or 230-v direct-drive unit

that is factory-connected for heating and cooling

speeds that are not the same, and same speed for

both heating and cooling is required for a particular

application, connect appropriate color-coded lead

to terminal 2 of cooling relay and connect a field-

supplied jumper between heat relay and terminal 2

of cooling relay. Be sure to properly insulate unused

motor lead(s).

17