Carrier 5H User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

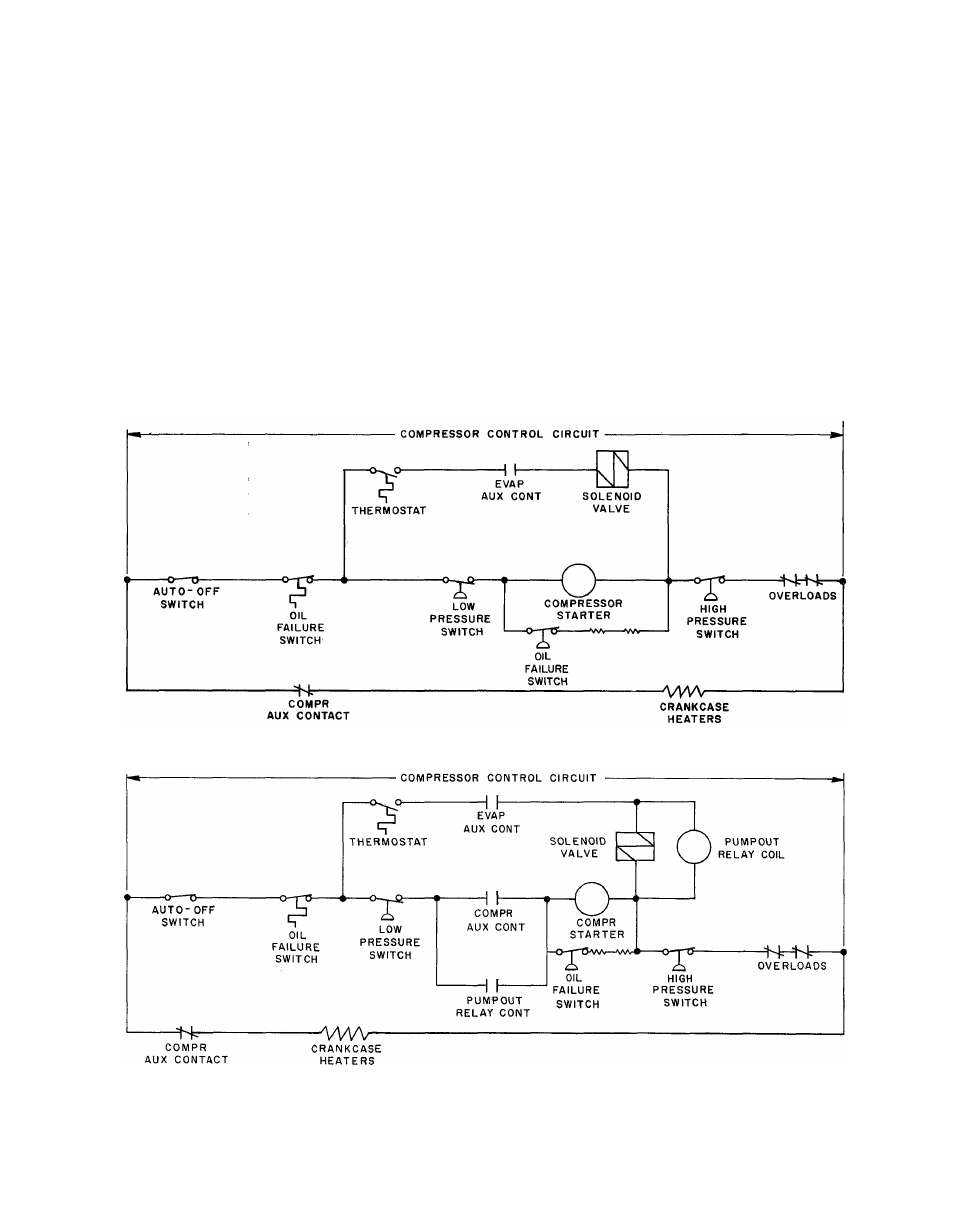

AUTOMATIC PUMPDOWN CONTROL (Fig. 2) -

Pumpdown control is the most effective means of

compressor control in keeping liquid refrigerant

out of the crankcase on system shutdown.

In the basic pumpdown control sequence the

thermostat controls the liquid line solenoid valve

to stop or start the flow of refrigerant to the evap

orator as required.

The pumpdown control system permits com

pressor cycling if a system malfunction allows the

low side pressure to rise. Although this cycling

is sometimes considered objectionable by the cus

tomer, it does promptly point out the need for

maintenance attention and provides positive pro

tection against liquid refrigerant accumulating

in the compressor crankcase.

Pumpdown control should not be used with dry

expansion coolers as it may cause frost pinching

or freeze-up.

SINGLE PUMPOUT CONTROL - Pumpout control

is not as positive as pumpdown control in keeping

liquid refrigerant out of the crankcase. However,

it is usually satisfactory when used with crankcase

heaters if pumpdown is not acceptable.

Single pumpout control is similar to pumpdown

control, except in the following ways: a pumpout

relay is added, a normally open compressor auxil

iary contact is necessary, and energizing of crank

case heaters is definitely required at the end of

each operating cycle.

With single pumpout control, when the thermo

stat is satisfied, the compressor pumps down once

and stops. It starts again only when the thermostat

calls for cooling. In pumpdown control, the com

pressor cycles solely on the low pressure switch,

regardless of the demands of the thermostat.

Pumpout control should not be used with dry

expansion coolers as it may cause frost pinching

or freeze-up.

Fig. 2 - Automatic Pumpdown Control

Fig. 3 - Single Pumpout Control

SECTION

PAGE

DATE

5F,H-1XA

6

10-66

S U P E R S E D E S

SECTION

5F,H-1X

PAGES

1-42

DATE

11-63