Control pressurestat for booster application – Carrier 5H User Manual

Page 28

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Three

common

methods

of

gas

desuperheating

and

liquid

cooling

for

direct

stage

systems

are

illustrated in Fig. 15. In the open type systems,

the refrigerant liquid is cooled down to the satura

tion

temperature

corresponding

to

the

interme

diate pressure. In the closed type systems, good

intercooler

design

usually

results

in

the

refrig

erant liquid being cooled down to 10 to 20 degrees

above

the

saturation

temperature

corresponding

to

the intermediate pressure.

Oil Separators and Lubrication

- In Freon cas

cade type systems, where evaporators and suction

lines are properly designed for oil return to the

compressor, oil separators are not usually used.

In

direct

staged

systems,

however,

oil

may

tend to accumulate in one of the stages and thus

result in lack of lubrication in the other machine.

By the use of oil transfer lines, equalization of

the oil level between crankcases can be achieved

by

manual

operation

at

periodic

intervals.

Auto

matic control of proper oil return to both com

pressors is effected by the use of a high stage

discharge line oil separator, returning oil to the

high stage machine, and a high side float, connected

to the high stage machine crankcase, which contin

ually drains excess oil from this crankcase down

to the next lower stage compressor (Fig. 15).

For booster application, the factory oil charge

should

be

drained

and

replaced

with

a

suitable

viscosity oil for the low temperature application.

Control Pressurestat for Booster Application -

The standard dual pressure switch furnished with

the

5F,H

compressors

is

not

suitable

for

use

with booster application. It must be replaced with

one of the appropriate low temperature dual pres

sar estats from Table 21.

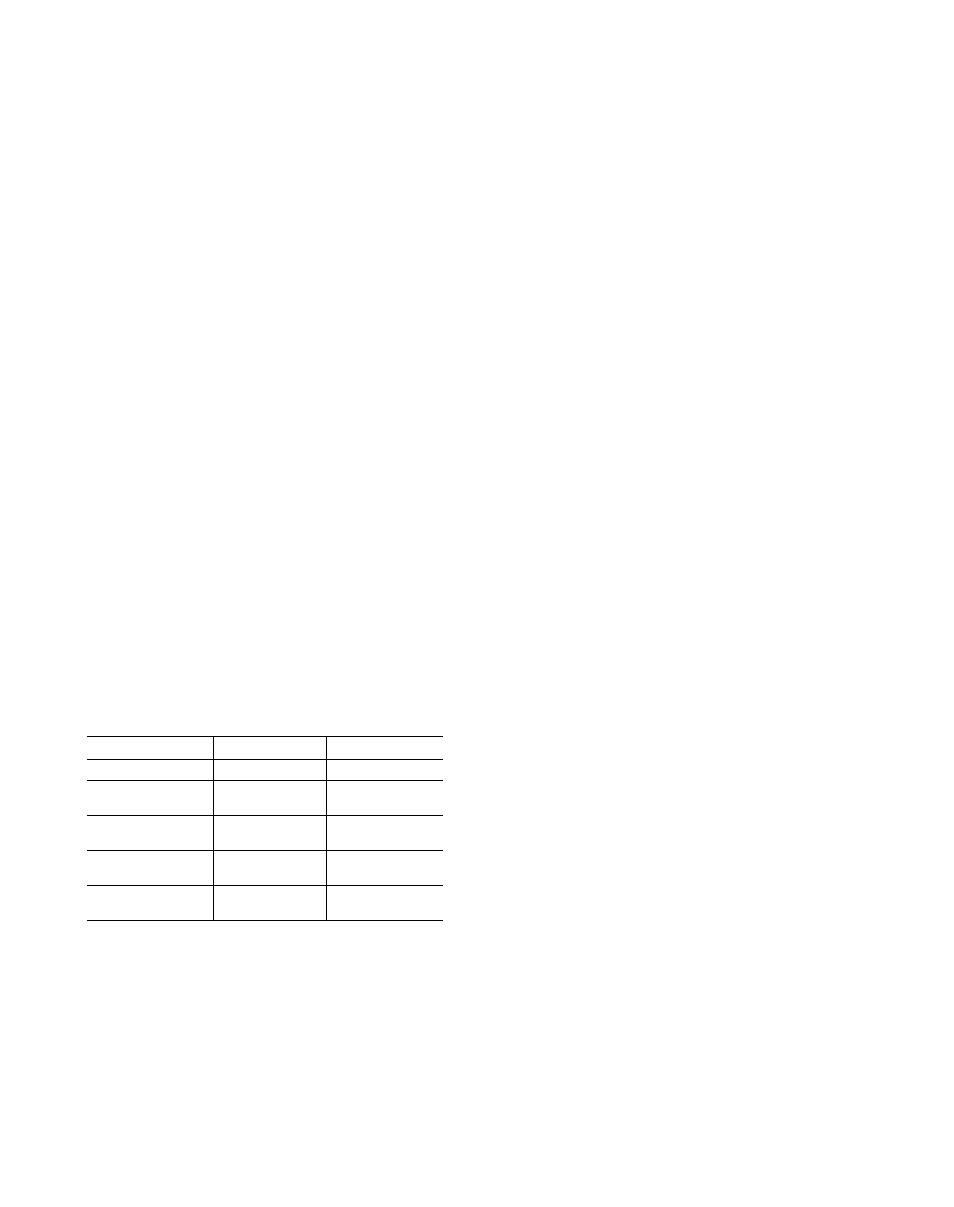

Table 21 - Control Pressurestats for Low

Stage Application

REFRIGERANT 12

REFRIGERANT 22

CARRIER PART NO

HK04HN-068

HK04HN-164

Switch Action - High

Open on press, rise

Open on press ri se

■ Low

Open on press fall

Open on press fall

Range - High

20" Vac. to 65 psig

30" Vac to 110 psig

- Low

30" Vac to 20 psig

30" Vac to 25 psig

Differential - High

8 to 30 psi adjust.

12 to 30 psi adjust

- Low

5 to 15 psi adjust.

9 to 30 psi adjust.

Max Pressure - High

200 psig

300 psig

- Low

120 psig

300 psig

Discharge Valve Springs

- When 5Hcompressors

are used for booster applications where the dis

charge

pressure

is

below

10

psig,

the

standard

discharge valve springs furnished with the machine

should be replaced with an equal number of lighter

weight springs. Part Number 5H41-1801.

No change in discharge valve springs is rec

ommended for the 5F compressors.

SECTION

PAGE

DATE

5F,H-1XA

28

10-66

Printed

Water-Cooled Heads

- The standard 5F,H com

pressors are not equipped with water-cooled heads

but

they

are

available

on

special

order.

Water

cooling of the heads is not generally necessary in

R-12

and

R-22

booster

applications.

For

these

applications with R-22 involving high compression

ratios,

5

or

above,

5F,H

booster

compressors

should be equipped with water-cooled heads.

Motor Selection Data

- In staged refrigeration

systems,

the

high

stage

compressor

starts

first

and runs until the low stage pressure has been

reduced to a predetermined level before the low

stage machine starts. With direct staged arrange

ments,

the

high

stage

machine

draws

gas

from

the evaporator thru the low stage machine bypass

during this initial period. The size of the selected

motor must be related to the maximum condition

at which the booster compressor can operate.

The

compressor

may

run

under

heavy

loads

during

periods

of

high

suction

pressure,

espe

cially on starting when the system is warm. To

handle these situations the motor must be sized

larger

than

the

actual

balanced

operation

brake

horsepower

indicates,

or

special

attention

must

be paid to the operation of the system when starting

initially.

If the system is to operate only at a fixed low

temperature,

it

is

generally

possible

to

avoid

oversizing of motors to any great extent, provid

ing careful operation is followed when the system

is first put in operation.

For

those

cases

where

definite

pulldown

pe

riods are involved, the motors must be sized to

handle

the

highest

brake

horsepower

occurring

during pulldown.

On

applications

requiring

reduction

in

tem

perature

from

ambient

conditions

to

some

ex

tremely

low

temperature,

the

compression

system

will

be

operated

at

high

suction

pressures

for

considerable

periods

of

time.

General

practice

here is to drive the high stage compressor with

a motor that will carry the compressor at the

highest

expected

evaporator

temperature.

This

is generally the "air conditioning" rating of the

unit.

For

intermediate

or

low

stage

compressors,

it is generally sufficient to size the motor to take

care of double the balance load indicated horse

power plus the friction horsepower.

It

is

also

necessary

to

consider

compressor

starting

torque

requirements

when

selecting

the

motor

for

a

booster

compressor.

The

starting

torque of a motor only large enough to provide the

required normal operating bhp for booster appli

cations, may not be large enough to start the com

pressor.

The

recommended

minimum

motor

sizes

shown in Table 22 have been selected to assure

adequate

starting

torque.

The

actual

motor

size

selected

is

usually

larger;

however,

depending

on the maximum bhp conditions under which the

compressor

will

run

during

pulldown

or

other

abnormal operating periods.

.

S U P E R S E D E S

SECTION

5F,H-1X

PAGES

1-42

inU.S.A.

DATE

11-63