Carrier 5H User Manual

Page 16

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

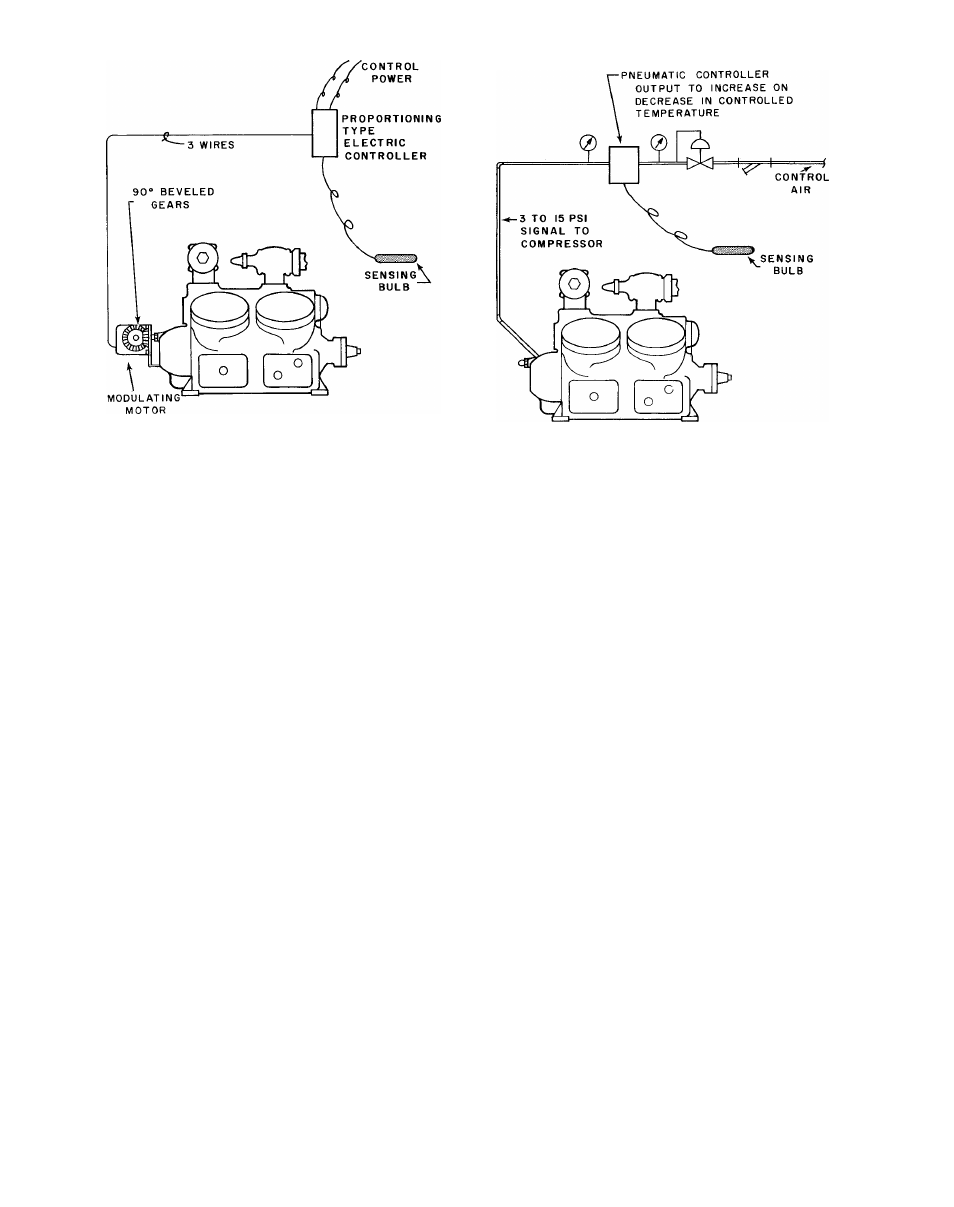

Fig. 11 - Electrical Compensation

Fig. 12 - Pneumatic Compensation

CONTROL PRESSURESTATS - Dual pressure-

stats are furnished with all 5F,H compressors.

They are often referred to as high and low pres

sure cutouts. Their function is to cut the circuit

to the holding coil of the compressor motor starter

whenever the pressure setting limits are exceeded.

The high pressurestat has an operating range

from 175 to 375 psig with a differential range

from 40 to 60 psig. The low pressurestat has an

operating range from 20” Hg. to 110 psig and a

differential range from 9 to 50 psi.

Pressurestat settings should be adjusted on

the job to meet the particular operating conditions

for which the compressor (s) have been selected.

Directions for setting these pressurestats will

be found in the 5F,H Installation Manual.

PERMANENTLY UNLOADED CYLINDERS - The

5F60, 5H40 and 5H60 compressors are available

with one cylinder permanently unloaded. The

5H120 is available with two cylinders permanently

unloaded. These compressors are unloaded by

removing the suction valve and suction valve

springs from one or two of the cylinders. The

unloaded cylinders are the first one or two which

unload during the normal unloading sequence of

the compressor.

CAPACITY CONTROL MODIFICATION FOR

HEAT PUMP APPLICATION - Where 5F40, 5F60,

and all 5H compressors are used in refrigerant

cycle reversing heat pump applications, it is

usually necessary to modify the standard capac

ity control arrangement to satisfy the unloading

requirements. On the summer cycle, the compres

sor is required to unload as the circulating water

or air temperature drops. During the winter cycle.

SECTION

PAGE

DATE

5F,H-1XA

16

10-66

Printed

it is necessary for the control to work in reverse,

so that the compressor unloads as this same cir

culating water or air temperature increases. To

accomplish these results, it is necessary for the

compressor to unload in response to either a sum

mer or winter temperature sensing device,depend-

ing on the particular cycle in operation.

Where the summer and winter design suction

temperatures are within the design range of either

electric or pneumatic compensation devices, the

capacity control may be external. This however,

is not too common and another means is normally

required.

Usually modification to the compressor capac

ity control system will be required. The com

pressor can be modified in two ways; (1) for

application requiring 50% capacity reduction, (2)

for applications requiring more than one step of

capacity reduction. See Fig. 13 for a typical two-

step external capacity control arrangement.

1.

Application Requiring 50% Capacity Reduc

tions -

This is the usual specification on heat

pump applications of this type and should cover

the majority of cases. The necessary modifica

tions to the compressor capacity control for

these arrangements can be accomplished by

special ordering from factory and with certain

field modifications.

a. Factory Modifications - The compressor

order should state that the compressor is

to be special for heat pump application, and

is to include only enough unloader power

elements to unload the compressor down to

50% displacement. The unloaded cylinders

will be those closest to the pump end of the

compressor.

S U P E R S E D E S

SECTION

5F,H-1X

PAGES

1-42

inU.S.A.

DATE

11-63