Refrigerant 12, 22, 500, and 502 compressors – Carrier 5H User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

REFRIGERANT 12, 22, 500, AND

502 COMPRESSORS

Operating Requirements

- Satisfactory operation

of a reciprocating compressor is largely depend

ent upon the recognition of these three fundamental

requirements:

1. Prevention of excess discharge temperature

2. Adequate compressor lubrication

3. A clean and dry system

Discharge Temperature

- The temperature at the

discharge valves within the cylinders is the con

trolling factor. Some cooling of the discharge gas

occurs before reaching the discharge stop valve,

thus when water-cooled heads are used this cooling

is greater than it is without water cooling. To pre

vent the occurrence of excessive temperature at

the discharge valves within the compressor, the

following temperatures when measured imme

diately following the discharge stop valve must

never be exceeded.

For nonwater-coOled heads - 275 F max

For water-cooled heads - 250 F max

The approximate discharge gas temperature

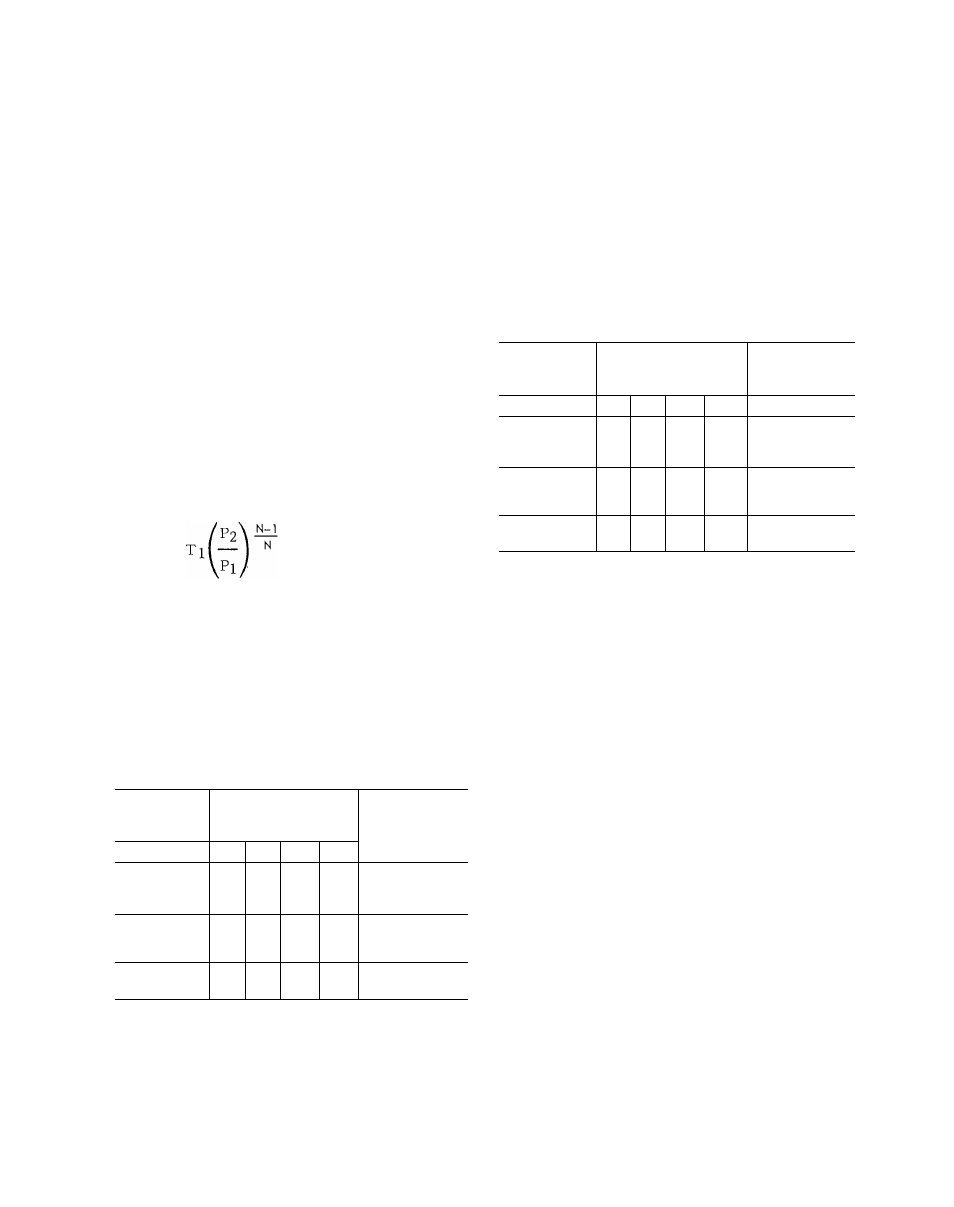

can be found by use of the following equation:

T2 =

Where:

T2 ^

Tl ^

P2 ^

Pi ^

N

Discharge temperature, F absolute

Suction temperature, F absolute

(including superheat)

Discharge pressure, psia

Suction pressure, psia

Compression exponent of the gas

(Table 4)

Table 4 - Compression Exponent ”N'

COMPRESSION

RATIO =

Discharge psia

. WITHOUT

WATER-COOLED

HEADS

WITH

WATER-COOLED

HEADS

R-22

Suction psia

R-12, :

r

-22

R-500 R-502

2

1 216 ,1 325 1 258 1 234

1 240

3

1 191 1 258

1 216 1 216

1 218

4

1 177 1.240

1 203 1 206

1 205

5

1 172 .1.234 1.196 1 197

1 3 99

6

1 166 1 232

1 191 1.190

1.196

8

1.160 1.228

1.186 1.178

1 192

10

1.155 1.225

1 182 1.169

1.187

12

1 150 1.224

1 179 1 161

1 182

The value of the compression exponent (N)

depends upon several factors such as - proper

ties of the gas compressed, degree of cooling in

the compressor jacket, leakages, etc.

In order to simplify discharge temperature

calculations, the preceding formula maybe stated

in the following form:

T2 = [(460 + Tl) X C] - 460

Where:

T

2

= Discharge temperature, F actual

Tl = Suction gas temperature, F actual

(including superheat)

0

.

Values for C at various compression ratios are:

Table 5 - "C” Factors

COMPRESSION

RATIO =

Discharge psia

WITHOUT

WATER-COOLED

HEADS

WITH

WATER-COOLED

HEADS

Suction psia

R-12

R-22

R-500

R-502

R-22

2

1 14

1 17

1.16

1 13

1.15

3

1 19

1 25

1.22

1 22

1 22

4

1.23

1 31

1 26

1 27

1.27

5

1 26

1 36

1,30

1 30

1 31

6

1 29

1 40

T

3 3

1 33

1 34

8

1 33

1.47

1:39

1.37

1 40

10

1.36

1 53

1 43

1 40

1 44

12

1 38

1 57

1 46

1 41

1 47

SECTION

PAGE

DATE

5F,H-1XA

4

10-66

Printed in U.S.A.

Example:

Refrigerant 12

Compression Ratio — “ °

Factor C = 1.33

Suction Temperature, Tl = 0 F Saturated,

Superheated to 65 F

Solution:

'

T2 = [(460 + 65)

X

1.33] - 460

= 698 - 460

= 238 F

Although exponents are shown for high com

pression ratios, these are for information pur

poses only. The rating tables define the allowable

selection and operation limits.

High Compression Ratio

- Avoid compressor op

eration at compression ratios exceeding those

covered in the rating tables. For operating condi

tions outside the limits .shown in the tables, use

two-stage compression. Care must be taken to

prevent the compressor from pulling down to

levels outside the rating tables.

Suction Gas Superheat

- Excessive suction gas

superheat will result in abnormally high discharge

temperatures which must be avoided. When using

Refrigerants 12, 500, and 502 the actual suction gas

temperature must not exceed the values listed in

Table 6.

,

S U P E R S E D E S

SECTION

5F,H-1X

PAGES

1-42

DATE

11-63