Carrier 5H User Manual

Page 26

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

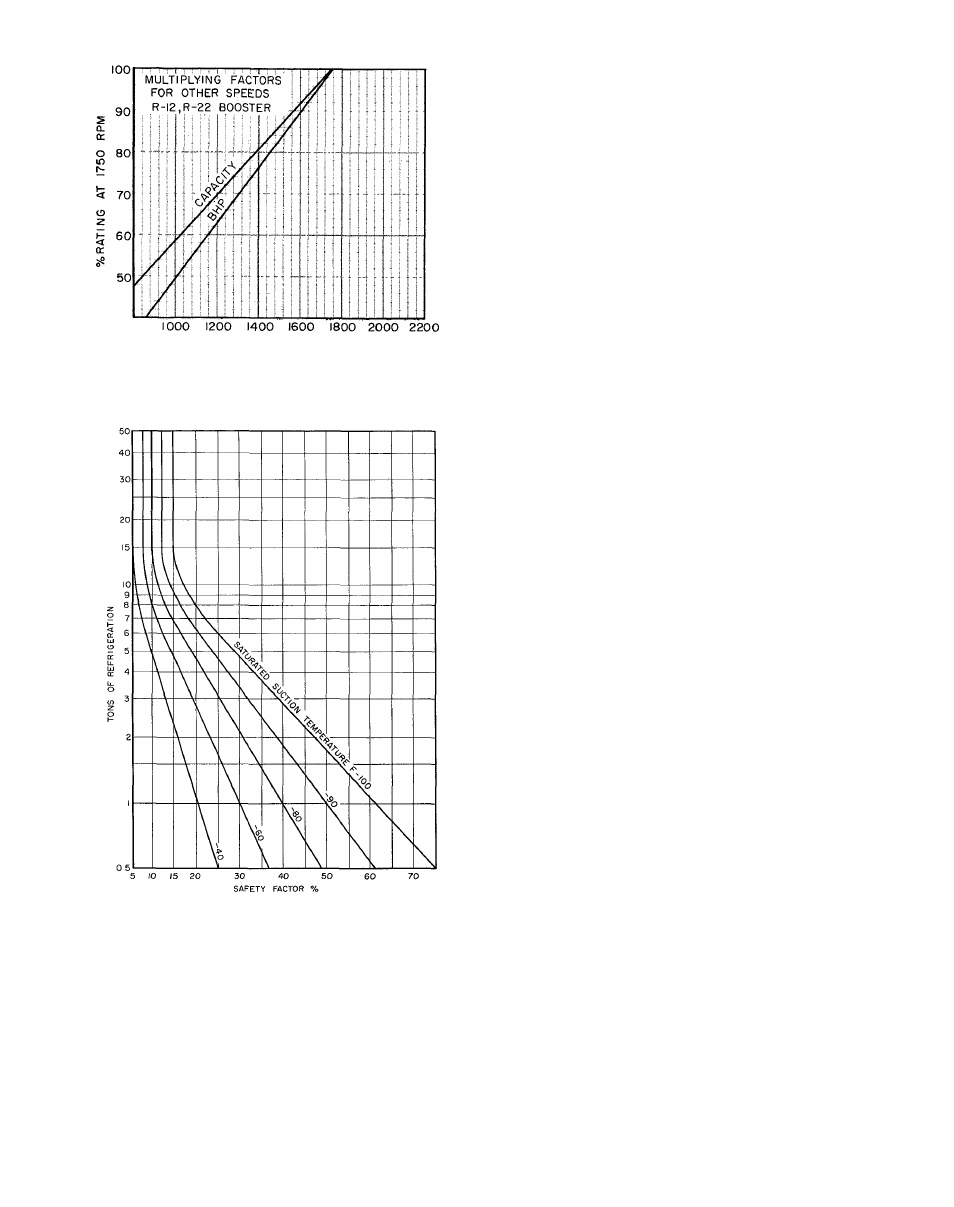

SPEED (RPM)

Fig. 16 - Multiplying Factors - Nonstandard

Speeds

Fig. 17 - Booster Compressor Selection

Safety Factors

Safety Factors

- The use of capacity safety fac

tors

in

selecting

booster

compressors

must

necessarily be a matter of judgment on the part

of the engineer making the selection.

Factors

which

have

a

bearing

on

satisfactory

compressor

selections

are:

the

accuracy

of

the

load estimate, the amount of safety factor included

in the total load, knowledge of the degree of impor-

SECTION

PAGE

DATE

5F,H-1XA

26

10-66

Printed

tance of meeting the specified capacity at the given

condition, the temperature level of operation and

the magnitude of the refrigeration load. All of the

factors must be recognized when considering the

use

of

a

capacity

safety

factor

in

selecting

a

booster compressor.

Figure

17

presents

reasonable

safety

factors

for use in the selection of booster compressors.

These can be employed when it is not desired to

e stablish a factor based on the selector's judgment.

When

a

capacity

safety

factor

is

used,

the

compressor

is

selected

at

its

maximum

speed

to handle the design load plus the amount of safety

factor.

Whether or not the added capacity offered by

the safety factor is incorporated at once is a mat

ter of judgment. If it is, then the compressor will

be operated at maximum speed right at the start

and any excess capacity achieved will be reflected

in faster pulldowns or lower temperatures. It is

also, however, good practice to drive the machine

at the speed which will provide slightly more rated

capacity than is required by the design load. The

additional

speed-up

available

will

then

constitute

reserve capacity in the event that it is needed.

Motors should be sized to run the compressor at

maximum

speed

to

forestall

any

motor

changes,

should

this

maximum

compressor

speed

be

re

quired in the future.

Determining Intermediate Pressure-

in the appli

cation of commercial compressors to staged sys

tems, it is found that the lowest total bhp per ton

and

most

economical

equipment

selection

results

when

using

approximately

equal

compression

ratios for each stage. However, it is also econom

ical to juggle assigned compression ratios slightly

to fit available sizes of machines.

The use of Fig. 18 will allow direct determina

tion

of

the

proper

intermediate

pressure

which

will result in equal compression ratios per stage

for

direct

two-stage

system.

The

information

in

Fig. 18 is given in terms of saturated temperature

instead of pressures, for easier use with the com

pressor ratings.

The existence of a second appreciable load, at

some

higher

suction

pressure

level,

will

very

often

dictate

the

most

convenient

intermediate

pressure.

Gas Desuperheating

- The operation of a direct

staged system requires cooling of the gas between

stages.

Otherwise,

the

highly

superheated

dis

charge gas from the low stage machine would be

taken directly into the suction of the higher stage

compressor

and

further

compression

would

result

in excessive heating of this compressor.

Liquid Cooling

- It is also necessary to employ

liquid

cooling

between

stages

and

increase

the

refrigeration effect of the liquid delivered to the

evaporator

to

realize

the

rated

capacity

of

the

booster

compressor.

The

amount

of

refrigeration

expended in cooling the liquid between stages is

accomplished much more economically at the level

of the high stage compressor suction than at the

level of the low stage suction.

S U P E R S E D E S

SECTION

5F,H-1X

PAGES

1-42

inU.S.A.

DATE

11-63