Keeping liquid refrigerant out of compressor – Carrier 5H User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Table 6 - Actual Suction Gas Temperature

Limits (F) Refrigerants 12, 500, and 502*

SAT SUCTt

GAS TEMP

■60 -50 -40 -30 -20 -10 0 and Above

Actual

Suction

Gas Temp

R-12

R-500

-

-

35

45

55

65

65

R-502

25

35

45

55

65

75

75

*With Refrigerant 22 the suction gas superheat should never

exceed 25 F for continuous operation.

tFor most saturated suction temperatures -10 F or below,

coolers are required. See rating pages for specific informa

tion.

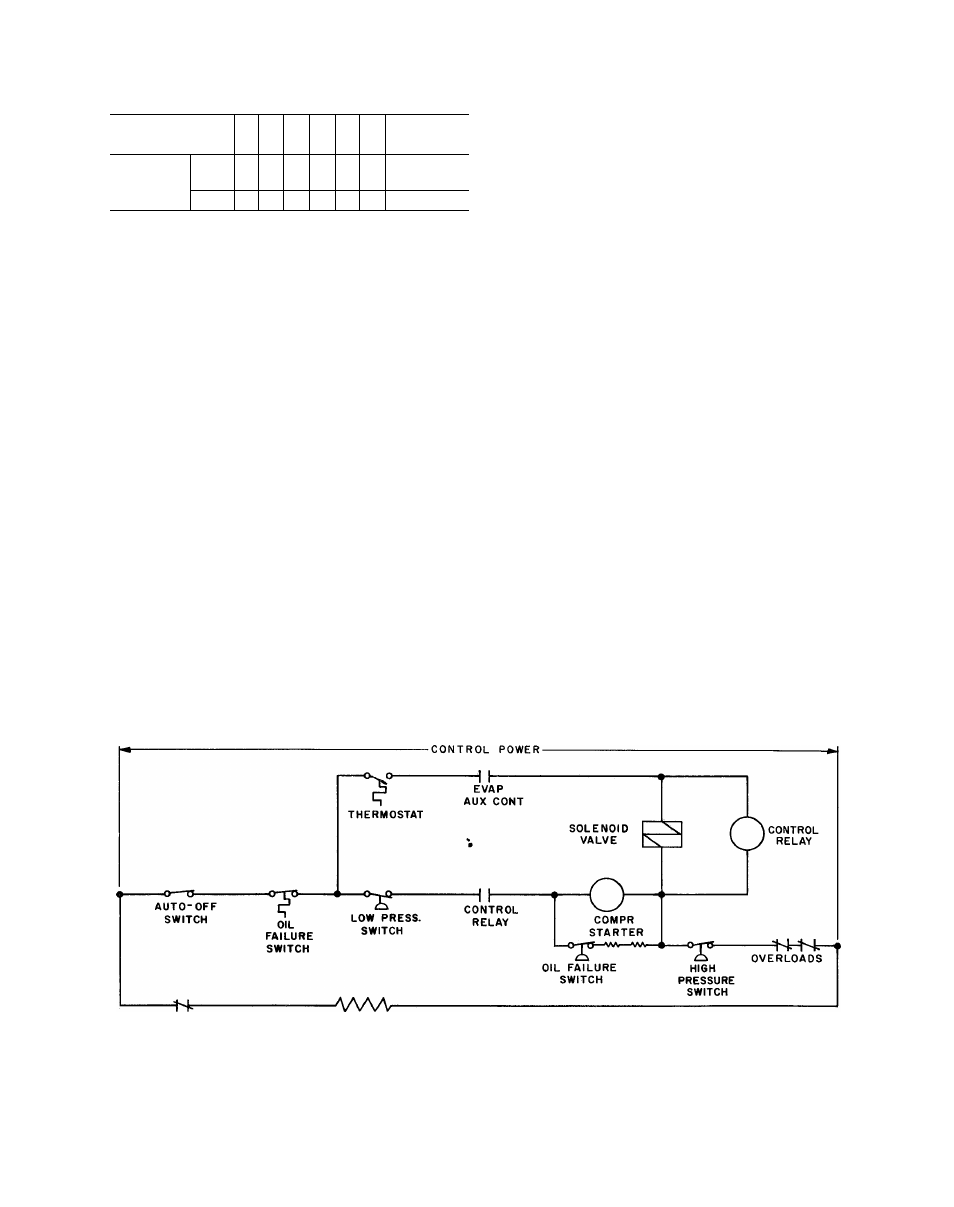

MINIMUM PROTECTION - The standard recom

mended control method (see Fig. 1) is to close,

by action of the control thermostat, the liquid

line solenoid valve and simultaneously energize

the crankcase heaters. With the crankcase heaters

energized the crankcase temperature is always

held above the shutdown temperature in the evap

orator coil and there will be no refrigerant migra

tion to the crankcase.

With this type control a control relay is re

quired and the crankcase heaters have to be en

ergized whenever the compressor is not operating.

Keeping Liquid Refrigerant Out of Compressor -

Liquid refrigerant, or even excessive amounts of

entrained liquid particles, in the suction gas must

be kept out of the compressor by proper system

design and compressor control. Under running

conditions, the presence of unevaporated liquid

refrigerant in the compressor tends to break down

the oil film on the cylinder walls resulting in

increased wear and loss of machine capacity.

During compressor operation, proper adjust

ment of the expansion valve will prevent excessive

amounts of liquid from entering the compressor.

During compressor shutdown, gravity, thermal

action and refrigerant absorption will result in a

refrigerant and oil mixture in the compressor

crankcase. Gravity flow can be prevented by the

use of recommended loops, but thermal action and

the absorption of refrigerant by the lubricating oil

cannot be prevented by piping design.

For the above reason, the compressor must be

controlled during idle times by one of the follow

ing methods.

The control relay coil is located in parallel with

the liquid line solenoid and a normally open control

relay contact added in series with the compressor

starter and other auxiliary safety devices.

When the thermostat calls for cooling, solenoid

valve opens and control relay is energized. This

closes the relay contact and, if other safety devices

are in their normal position, compressor willstart.

Simultaneously the normally closed compressor

auxiliary contact will open, removing the crank

case heaters from the circuit.

When the thermostat is satisfied, the solenoid

will close and the control relay is de-energized.

This opens the relay contacts and the compressor

stops. This action causes compressor auxiliary

contacts to close energizing the crankcase heaters.

Specifications are sometimes written to call for

a degree of protection greater than that afforded by

standard method. If this is the case, either single

pumpout or automatic pumpdown control may be

required.

COMPR

AUX CONI

CRANKCASE

HEATERS

S U P E R S E D E S

SECTION

5F,H-1X

PAGES

1-42

DATE

11-63

Fig. 1 - Minimum Protection

SECTION

PAGE

DATE

5F,H-1XA

5

10-66