Staggered implement type, Fieldware, Link 4.02 – TeeJet Fieldware Link User Manual

Page 23

19

98-05244-ENUS R1

Fieldware

®

Link 4.02

Staggered Implement Type

NOTE: When loading this profile type onto a console without a

Smartcable or SDM on the system, only values for Section 1

will be used and the implement type will be set to “Straight”.

All other section or ABSC information will be retained in the

background as unused parts of the profile.

Basic Properties

►Description – used to enter the name of the Machine Settings

profile.

►GPS Antenna Height – used to measure the height of the

antenna from the ground. Range is 0.0 to 32.81 feet /

0.0 to 10.0 meters.

►Guidance Width – used to enter the distance between the

guidelines. Range is 3.28 to 246.06 feet / 1.0 to 75.0 meters.

►Implement Type – used to select

Staggered

as the layout of

the sections for the applied product location.

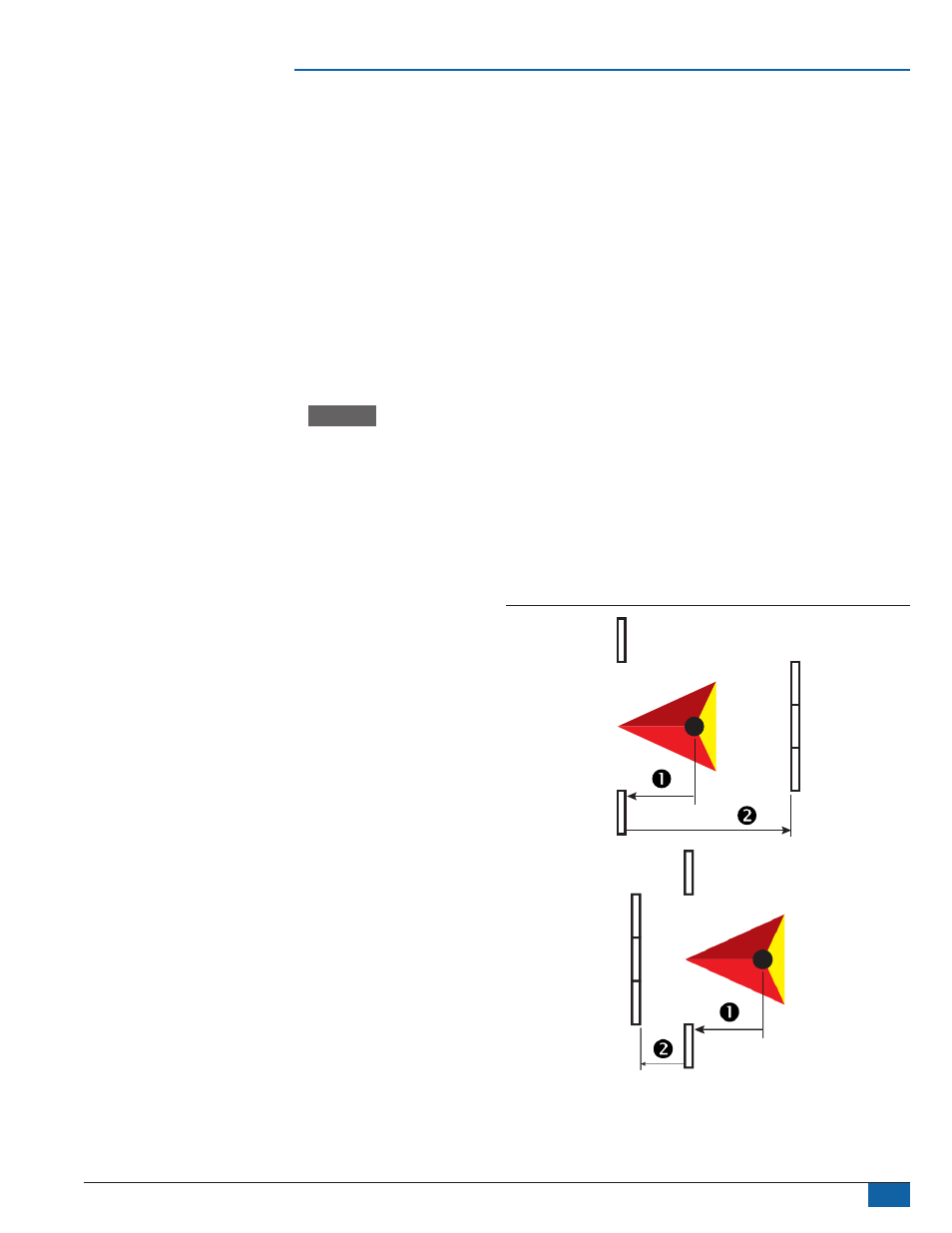

►Implement Offset Direction

– direction from the centerline of

the machine to the center of the implement while facing in the

machine’s forward direction

►Implement Offset Distance

– used to enter the distance from

the centerline of the machine to the center of the implement.

Range is 0.0 to 32.81 feet / 0.0 to 10.0 meters.

►Section 1 Offset Direction – used to select whether section 1

is located in front of or behind the GPS antenna as the vehicle

moves in a forward direction

►Antenna to Section 1 Distance

– used to enter the distance

from the GPS antenna to the section 1. Range is 0.0 to

164.04 feet / 0.0 to 50.0 meters.

►Number of Implement Sections – used to select the number

of implement sections. When ABSC Enabled is checked,

Smartcable and SDM options are available for editing.

►Tank Capacity – used to enter the capacity of the tank

►ABSC Enabled – used to enable ABSC (Automatic Boom

Section Control) options

• Unchecked – single section setup options will be available

(see “ABSC Enabled – Single Section Setup” section for

details)

• Checked – Smartcable or SDM setup options will be available

Implement Dynamics

►Delay On Time – used to set the time when each section will

switch on when entering an area that has not been applied. If

the application turns on too soon when entering an unapplied

area, decrease the delay on time. If the application turns on too

late, increase the delay on time. Range is 0 to 10 seconds.

►Delay Off Time – used to set the time when each section will

switch off when entering an area that has been applied. If the

application turns off too soon when entering an applied area,

decrease the delay off time. If the application turns off too late,

increase the delay off time. Range is 0 to 10 seconds.

►Section Width (under Application Width in Matrix Pro GS v3.xx) –

used to enter the width of each section of the implement. Each

section can be a different width. Sections are numbered from left

to right while facing in the machine’s forward direction. Range for

each section is 0.0 to 246.06 feet/ 0.0 to 75.0 meters. Total for all

sections must be greater than 3.28 feet / 1.0 meters.

►Section Offsets

– used to set the offset distance from

section 1 (the antenna to section 1 distance line) to each

section. Positive offset value will move the section behind

section 1. Negative offset value will move the section in front of

section 1. Section 1 is always 0 meters. All other sections can

be a different distances. Sections are numbered from left to

right while facing in the machine’s forward direction. Range is

-246.06 to 246.06 feet / -75.0 to 75.0 meters.

Job Specific Defaults

►Overlap – used to select the amount of overlap allowed when

the sections are turned on and off while using automatic boom

section control

Figure 43: Basic Properties