Operation and storage conditions, Trouble shooting, Contact pressure – TeeJet UniPilot User Manual

Page 16: Unipilot

14

www.teejet.com

UniPilot

®

operation and storage Conditions

Electronic components of the UniPilot ESM are designed for rough environmental conditions like agricultural applications. However it should

always be installed in the operator's station of the vehicle.

Warning! Never use a pressure washer to clean the UniPilot ESM. If needed wipe with a moist cloth.

Warning! Always protect the UniPilot ESM from falling onto a hard surface, to prevent internal damage.

Life expectance of the UniPilot ESM can be extended by storing it under optimal conditions. Keep all mounting screws and brackets together if

the motor is not installed in a stored vehicle. Avoid locations with high humidity as well as high temperatures near generators, radiators or near

windows in direct sunlight.

trouble shooting

Description

Cause

Troubleshooting

UniPilot ESM does not

turn

No signals from SCM (steering unit) to UniPilot ESM

Check steering system

Open wire between steering system and UniPilot ESM Check cable between steering system and UniPilot ESM

Open wire between power supply and UniPilot ESM,

UniPilot ESM is not supplied with voltage

Check power supply of UniPilot ESM

Contact wheel of

UniPilot ESM slips on

steering wheel

Spring force of collapsible mechanism of UniPilot ESM

is too low

Check distance from contact wheel and stand by position.

Once verified then adjust contact pressure as stated below.

Increase spring force of collapsible mechanism of UniPilot

ESM (see page 35 for details)

Contact wheel of UniPilot ESM is worn

Replace contact wheel of UniPilot ESM (see page 36 for

details)

Contact Pressure

Should the contact wheel slip while activating the steering wheel, the contact pressure needs to be increased. Either slide the UniPilot ESM

towards the steering wheel or increase the spring preload.

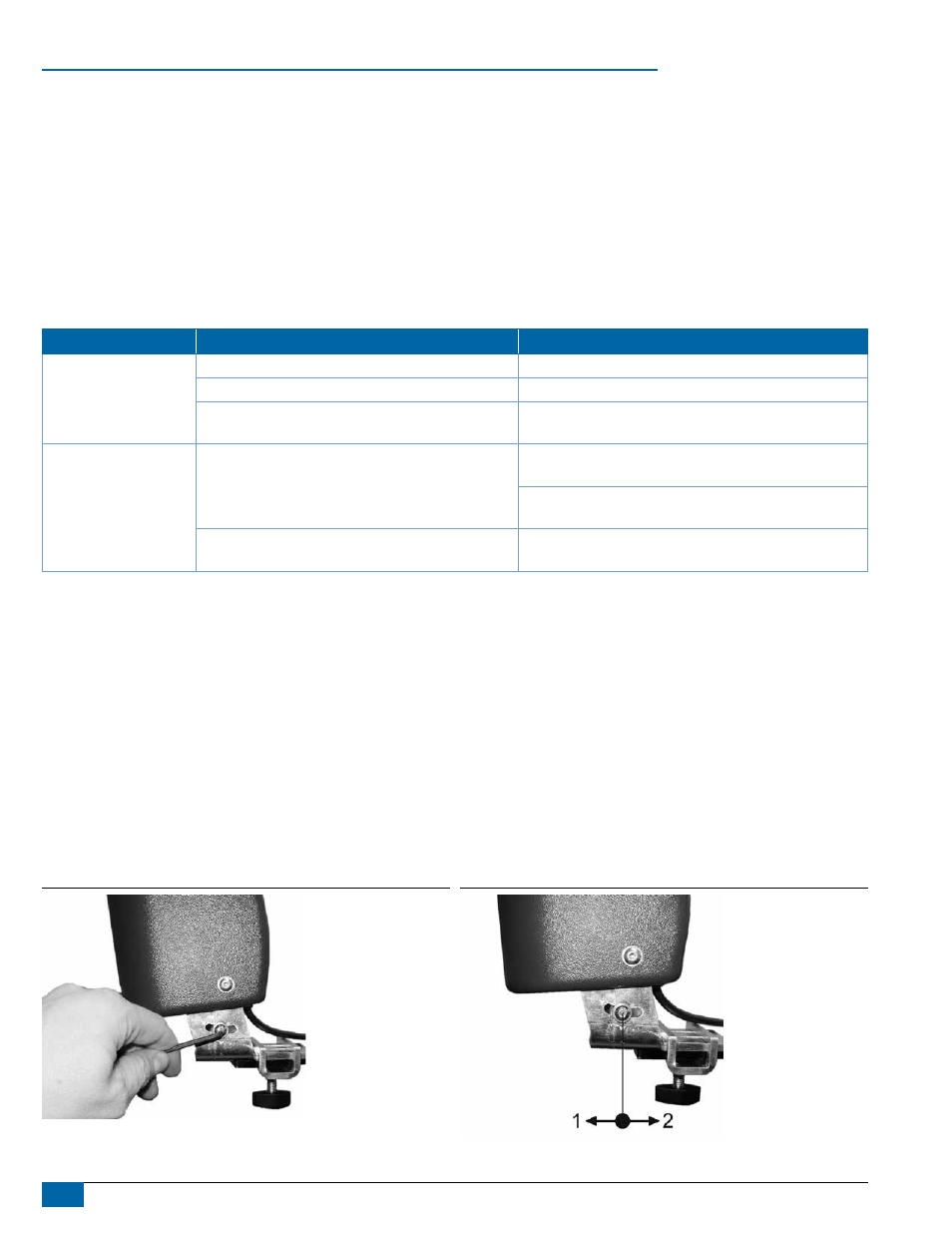

To Increase / Decrease the Spring Preload:

1. Disassemble the UniPilot ESM.

2. Bring the motor to the normal operating position, so that the spring tension against the two mounting screws is at it’s lowest.

3. Loosen the two mounting screws in the assembly base with a 2.5 mm allen wrench, if necessary hold the inside nut with a 8mm open end

wrench.

4. To increase pressure move the two mounting screws with the spring ends in direction (1) To reduce pressure move the two mounting screws

with the spring ends in direction (2).

5. Once you have the desired spring pressure tighten the two mounting screws.

6. Reassemble the UniPilot ESM to its mounting bracket on the steering column.

Figure 1-18: Loosen Mounting Bracket Screws

Figure 1-19: Increase/Decrease Spring Preload