Calibrations, Pulses per volume, Manual calibration – TeeJet IC18 SPREADER JOB COMPUTER User Manual

Page 29: Automatic calibration, Isobus job computer : ic18 spreader na

24

www.teejet.com

ISOBUS Job Computer : IC18 Spreader NA

OVER

VIE

W

SE

TUP

APPENDIX

GE

TTING ST

AR

TED

OPER

ATION

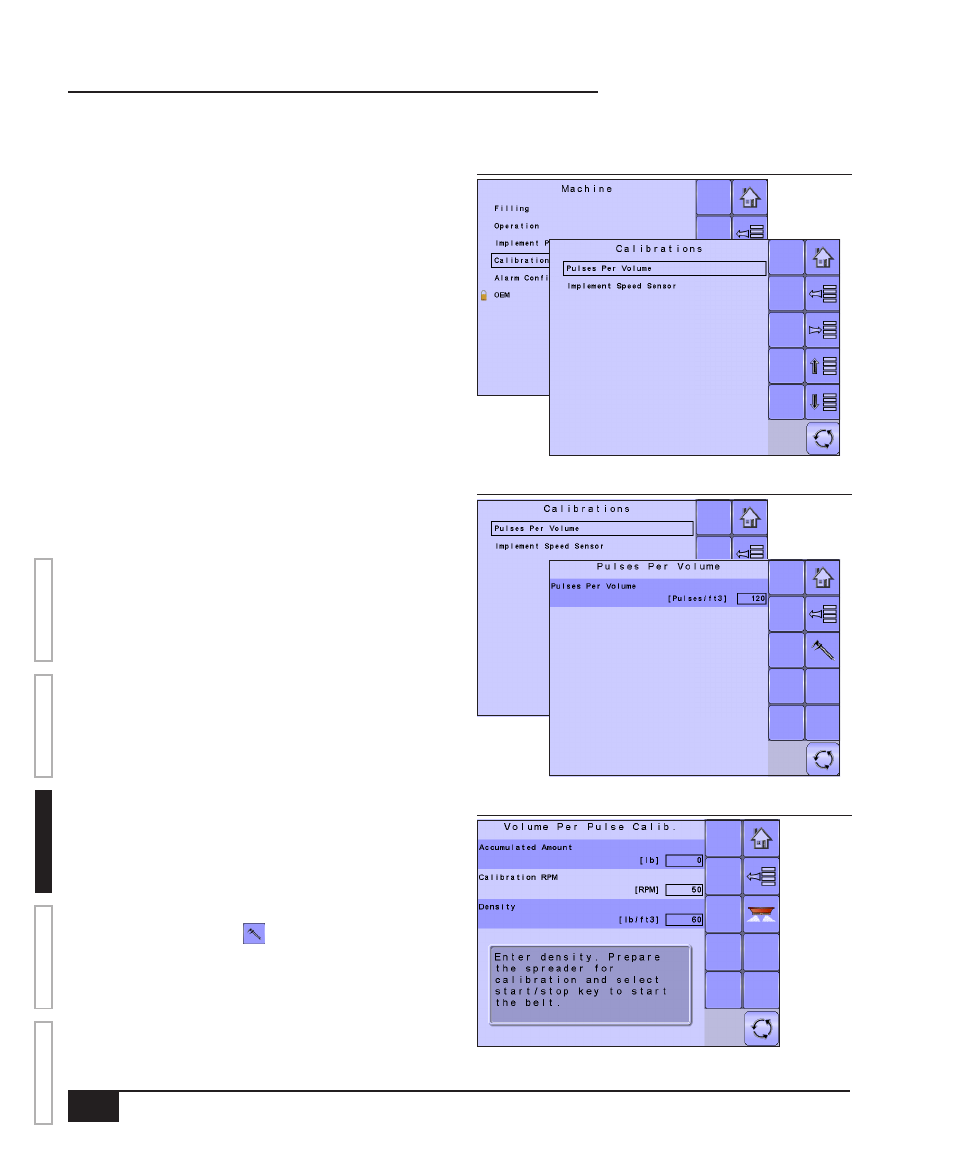

Calibrations

Figure 3-20: Calibrations

Figure 3-21: Pulses per Volume

Figure 3-22: Calibration Step One

Calibrations establishes either manual or automatic

settings of the sensors.

NOTE: For specific calibration options to appear, a

specific sensor needs to be installed. Sensor

availability is activated on the Sensor Presence

screen in the OEM section.

Pulses Per Volume

Pulses Per Volume establishes number of pulses for one

(1) cubic foot or one (1) cubic centimeter. This value can

be established manually or calibrated automatically. Each

type of spreader has a variety of variables that factor

into the pulses per volume number (roller diameter, gate

height and width, sensor type, type of belt or chain, etc.).

The pulses per volume number factors these variables

into the spreader output

Note: The calibration is based on the Reference Gate

Height, which defaults to 4 inches / 10 cm. This

number is accessed in the OEM Menu. The actual

Gate Height during calibration MUST match the

reference gate height setting.

Manual Calibration

Manual calibration establishes the pulses based on a user

entered value.

• To select the Pulses per Volume, use the number

pad or slide bar.

Automatic Calibration

Automatic calibration establishes the pulses using the

automatic calibration function.

• To calibrate the pulses per volume, select

CALIBRATION KEY .

• Follow the series of instructions displayed.

NOTE: Material will be dispensed during this procedure.

Be sure that a collection device is in place so that

a proper volume can be determined.