Sonics E-Press User Manual

Page 27

Sonics E-Press Manual

Page 27

when file operation or communications are in process. This indicator does not have any associated

operator interaction.

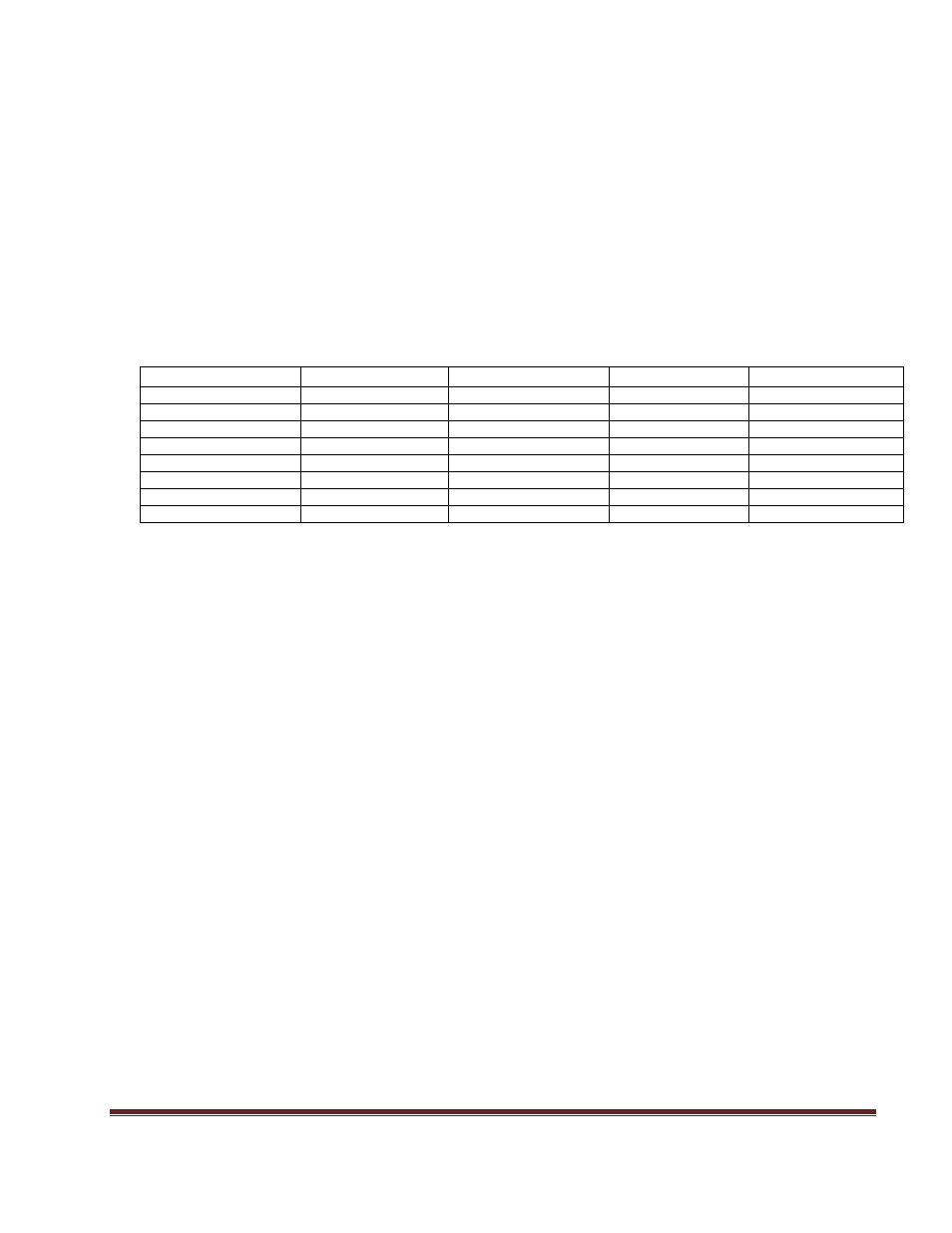

11.15 Scales and Limits

–The following table shows the allowed ranges for programmed entries on the

stepper controls screen. When switching from Metric to English (or the reverse), the entries are set to

default conditions. The operator must select appropriate entries for the welding application. Scales are

selected for closest whole digit resolution and presentation).

Table 12.1

Parameter

English-ABS

English-INC

Metric-ABS

Metric-INC

Force Trigger (FT)

010 – 150 LBS

010 – 150 LBS

50-650 Newtons

50-650 Newtons

Travel Distance (T1)

0.2 –2.7 In

0.2 –2.7 In

05– 70 mm

05– 70 mm

Weld Velocity 1 (R1)

0.01-10.00 RPS

0.01-10.00 RPS

0.01-10.00 RPS

0.01-10.00 RPS

Weld Distance 1 (WD)

0.0500 – 2.7500 In

0.0010 – 0.5000 In

1.000 – 70.000 mm

0.01 – 12.70 mm

Weld Velocity 2 (R2)

0.01-10.00 RPS

0.01-10.00 RPS

0.01-10.00 RPS

0.01-10.00 RPS

Weld Distance 2 (WD)

0.0000 – 2.7500 In

0.0000 – 0.5000 In

0.000 – 70.000 mm

0.000 – 12.700 mm

Upper Tolerance (P1)

0.0010 – 0.1000 In

0.0010 – 0.1000 In

0.025 – 2.500 mm

0.025 – 2.500 mm

Lower Tolerance (P2)

0.0010 – 0.1000 In

0.0010 – 0.1000 In

0.025 – 2.500 mm

0.025 – 2.500 mm

11.16 Menu Items -

The top line of the stepper setup form contains drop down menus for file functions, screen

switching, initiating the Windows calculator and a basic help utility.

1. File Job Open or Save

– The File\ Job\ Open and Save functions allow the presently programmed

values for the motor controls to be saved and recalled to or from a specified file. The file selection is

handled in the standard windows style. When the user has selected a file for the open function, the data

will automatically be retrieved from the computer file and loaded into the motor controls. The save

function will capture the present motor control settings and save this data to the specified file for future

recall using the Open menu selection. For either case the progress bar will indicate the activity and the

Ready Text box will identify the operation.

2. File Print Settings

– The Print Settings selection under the File menu will initiate a print operation.

The present motor control settings will be sent to the printer along with a time and date stamp.

3. Recall Machine Settings

– The present machine settings may be recalled from the stepper control

process at any time by selecting the Recall Machine Settings option under the File menu. When the

operation is complete, the selection side of the setup form will be set to match the present machine

values. This action will retrieve the values from the controller and verify all display settings.

4. Monitor\Log

– The Monitor\Log menu selection will unload the stepper setup form and display the

Monitor\Logging form. The Monitor\Log form is intended to capture weld and distance data and present

one status line after each weld. This data may be logged to a text data file and\or sent to the system

print buffer.

5. Calc

– The Calc selection will launch the windows system calculator intended to assist the operator

with application setup. If the windows Calculator program cannot be found, a message box will indicate

the condition.