Parts contact diagram – Sonics E-Press User Manual

Page 18

Sonics E-Press Manual

Page 18

programmed velocities can reach the desired position within the timer/energy settings. Velocity

settings and distances, timers, limits and amplitude settings are all interactive and must be

considered when setting up a stepper application.

13. The system should be ready to try a weld, be sure that parts are installed prior to initiating a weld

cycle. Don’t damage the fixture or horn.

14. Simultaneously press the left and right palm buttons (black buttons) on the press base to begin a

weld cycle.

Further adjust the settings as necessary to produce the optimum weld cycle time by using the shortest

practical travel distance. If the Upper Tolerance number can be made smaller, the parts will be found faster

which also improves the cycle time. The Lower Tolerance number should be adjusted so that when no parts

are installed, the system will not hit the lower fixture! This is the end of the parts search zone which will cause

the system to retract if no parts are found! Do not allow the horn to contact the fixture.

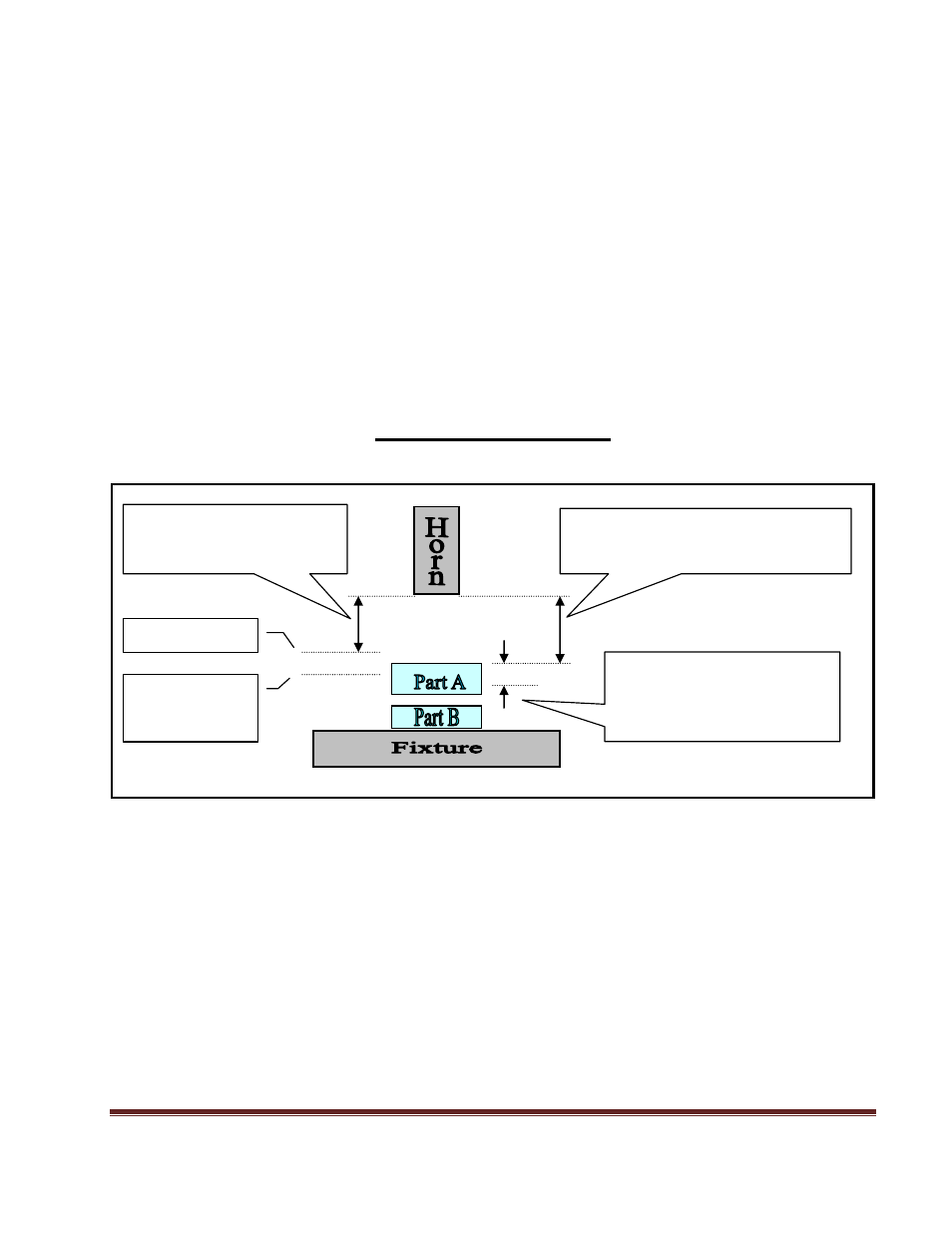

Parts Contact Diagram

Teach Position - The Distance to

unwelded parts with the programmed

force applied.

Upper Tolerance

Lower Tolerance

marks the end of

the search zone.

Parts Search Zone - Begin

searching for parts here.

(Teach minus upper tolerance)

Weld Distance - The incremental

weld distance is referenced from

the parts found position each

cycle.