Sonics E-Press User Manual

Page 24

Sonics E-Press Manual

Page 24

11.0 The Stepper Setup Screen

TOC

-

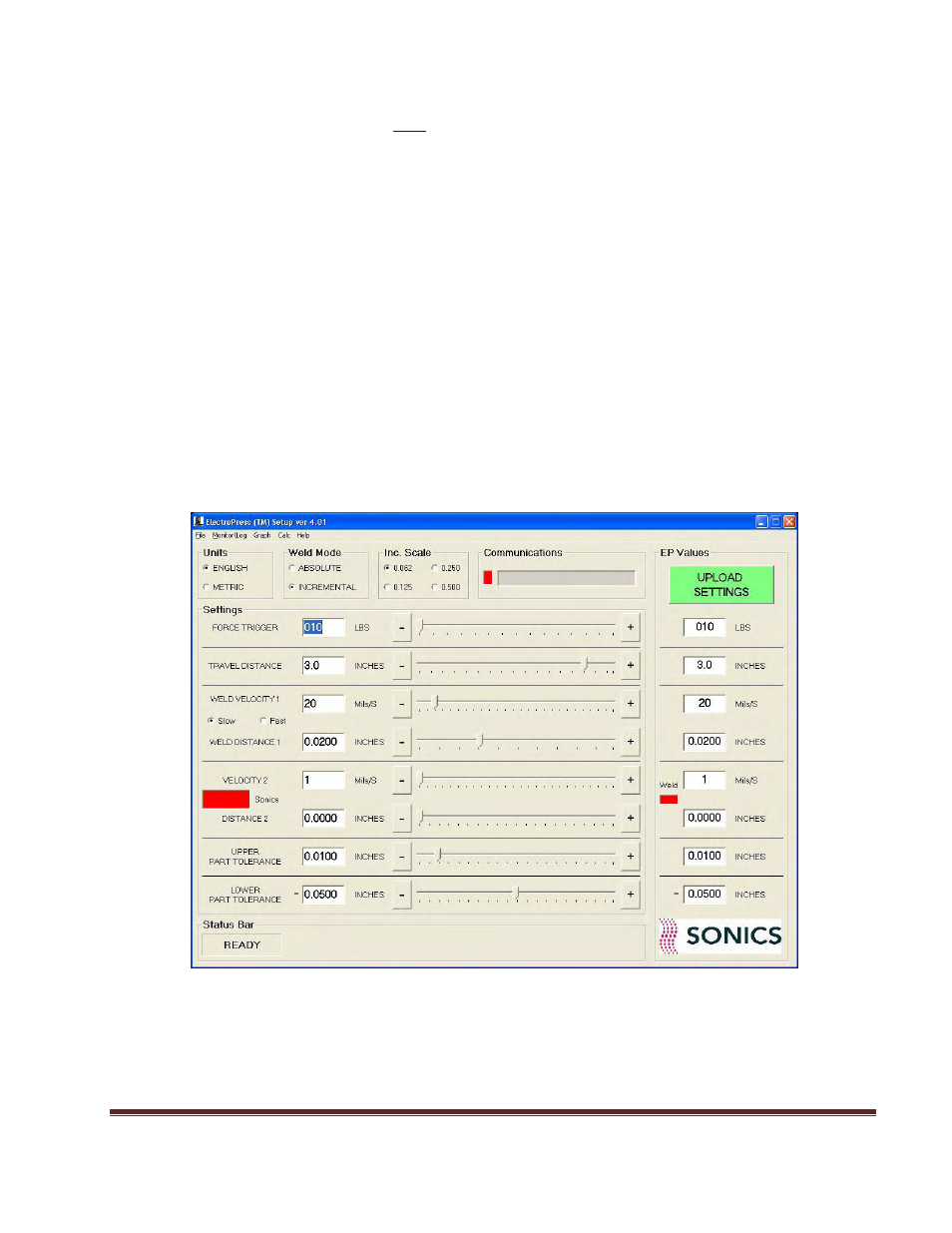

The E-Press motion settings are selected and programmed on

the E-Press setup screen. These include several motion and speed controls as well as setup information to

describe the welding application. The purpose for this screen is to type, slide or increment the control

parameter values until the desired settings are obtained in each text box on the left side of the screen. Select

the Units and Weld mode by clicking on the appropriate buttons. When the desired settings have been

entered, they can be transferred to the machine for use during the next weld cycle using the SET button. This

operation will take a few seconds to transfer and confirm. A progress bar will indicate a busy condition at the

bottom of the screen during this transfer. Note: Welding should not be initiated until the bar has stopped.

Upon completion of the SET function, the right hand side of the screen (Machine Values) will be identical to

the left hand side (desired settings). This approach minimizes the required communications between

controllers and preserves the non-volatile memory in the Stepper control system.

A typical setup screen is shown below and illustrates how the motion parameters are set and displayed. Each

item on the setup screen will be discussed in the following sections as it pertains to the motion control and

welding process. References to the GX ultrasonic power supply manual will help guide the user in setting the

associated ultrasonic controls. Several menu items are also available from the top toolbar for switching

screens and maintaining the application. The programming and control items will be addressed first followed

by the menu selections.

Stepper Setup Screen

Motion controls for Force, Weld Velocity and Weld Distance are settable using this screen. Numerical settings

may be adjusted in several ways. They may be typed into text boxes for exact selection or they may be

adjusted using the corresponding slide bar. These are standard controls that use the mouse to drag and drop

the settings or to increment or decrement the adjustment by one least significant count. Once the appropriate

selections have been made the settings are transferred to the motor controls using the SET button as

previously described.