0 maintenance and service (cont’d), 2 maintenance procedures (cont’d) – Reznor UDAS Unit Installation Manual User Manual

Page 34

Page 34

10.2.8 Combustion Air

Pressure Switch

See

FIGURE 18, page 30, for location. (NOTE: Depending on date of manufacture and

size, pressure switch may not be in the location indicated. Check the control bracket

on the bottom of the compartment or further down on the compartment wall.) If it is

determined that the pressure switch needs replacing, use only the factory-authorized

replacement part that is designed for the model and size of heater being serviced.

NOTE: A unit operating above 6000 ft (1830M) elevation requires a high altitude pres-

sure switch. See Paragraph 3.2.

If it is determined that the limit control needs replacing, use only a factory-authorized

replacement part that is designed for the size of heater.

For approximate limit location, see

FIGURE 18, page 30.

10.2.9 Limit

Control

NOTE: Operational

pressure settings and

instructions for checking

pressure settings are in

Paragraph 6.1.

2) With the manual valve turned off to prevent flow to the gas valve, connect a

manometer to the 1/8” outlet pressure tap in the valve. NOTE: A manometer (fluid-

filled gauge) is recommended.

3) Turn the manual valve to the ON position and the heater OFF. Use your finger to

fully block the main burner orifice for several seconds. Observe the manometer

with the orifice blocked, and if any pressure is indicated, the gas valve is leak-

ing.

A leaking gas valve must be replaced before the heater is put back in

operation.

10.2.10 Flame Rollout

Switch - Sizes 30-125

only

For location, see

FIGURE 18, page 30.

The cause of a flame rollout switch activating must be determined. Activation of the

manually reset flame rollout switch could be caused by one or more of the following:

• Restricted combustion air inlet or exhaust outlet

in combination with a defective pressure switch

• Electrical power interruption during operation

• Unit being operated with a line voltage

disconnect (a 24-volt thermostat is required)

If a flame rollout switch trips, inspect the burner/control compartment for signs of

excessive heat and burned wiring.

If the compartment appears normal, reset by depressing the red button on the

switch. 15 to 20 minutes are required for the switch to cool sufficiently for reset-

ting. A distinct click will be felt when the switch resets. Operate the furnace. If the

flame rollout switch trips again, determine and correct the cause before resetting

the switch.

If there is damage to the control compartment, repairs must be made before

resetting the switch.

If it is determined that the flame rollout switch needs replacing, use only the factory-

authorized replacement part that is designed for that size of heater.

The disconnect switch is located in the sealed electrical box inside the control com-

partment with the toggle on the rear of the heater.

• Restricted or plugged heat

exchanger

• Too much building exhaust

• Manifold gas pressure too

high

10.2.11. Door

Switch - Separtated

Combustion Model

only

If it is determined that the door switch needs replacing, use only a factory-

authorized replacement part that is designed for the heater.

For approximate switch location, see

FIGURE 18, page 30.

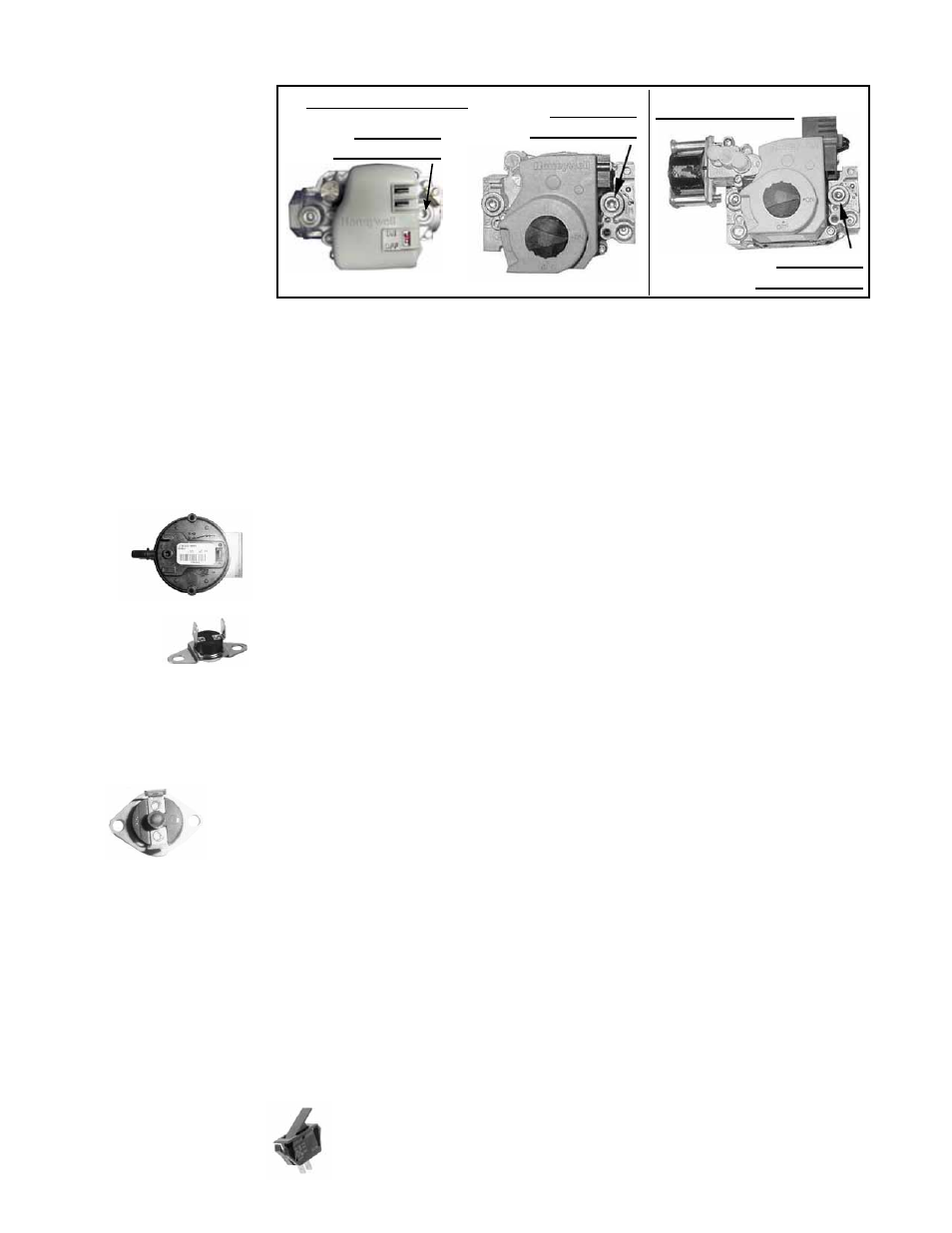

FIGURE 24 - Pressure

Tap for Checking Gas

Flow Shutoff

10.0 Maintenance

and Service

(cont’d)

10.2 Maintenance

Procedures

(cont’d)

10.2.7 Operating Gas Valve (cont’d)

Single-Stage Valves

1/8” Outlet

Pressure Tap

1/8” Outlet

Pressure Tap

Two -Stage Valve

1/8” Outlet

Pressure Tap