0 mechanical (cont’d), 1 gas piping and pressures (cont’d) – Reznor UDAS Unit Installation Manual User Manual

Page 14

Page 14

2. Locate the 1/8” output pressure tap on the valve (See FIGURE 10, page 13). Turn

the knob or switch on the top of the valve to “OFF”. Connect a manometer to the

1/8” pipe outlet pressure tap in the valve. Use a water column manometer that is

readable to the nearest tenth of an inch.

3. Single-Stage and Two-Stage High Fire - Turn the knob or switch on the top of

the valve to “ON”. Remove the cap from the pressure adjusting screw and adjust

the gas train pressure to the pressure selected from the table above. Adjust

pressure by turning the regulator screw IN (clockwise) to increase pressure or

OUT (counterclockwise) to decrease pressure.

Two-Stage Low Fire - Disconnect the wire from the “HI” terminal on the gas valve

and check the low fire pressure. Turn the regulator screw to adjust the low fire

outlet pressure to the “Low Fire” pressure selected from the table. Re-connect the

wire to the gas valve.

4. Turn up the thermostat. (NOTE: On a Separted Combustion model, depress and

hold the door safety switch.) Cycle the burner once or twice to properly seat the

adjustment spring in the valve.

Re-check the pressure(s). When the outlet pressure is right for the installation,

remove the manometer and replace the cap.

Check for leak at the pressure tap fitting.

6.1.3 Derate by Valve

Outlet Pressure

Adjustment for High

Altitude Operation

Instructions for High Altitude Derate

1. Determine the required valve outlet pressure for the elevation where the heater will

be operating. If unsure of the elevation, contact the local gas supplier.

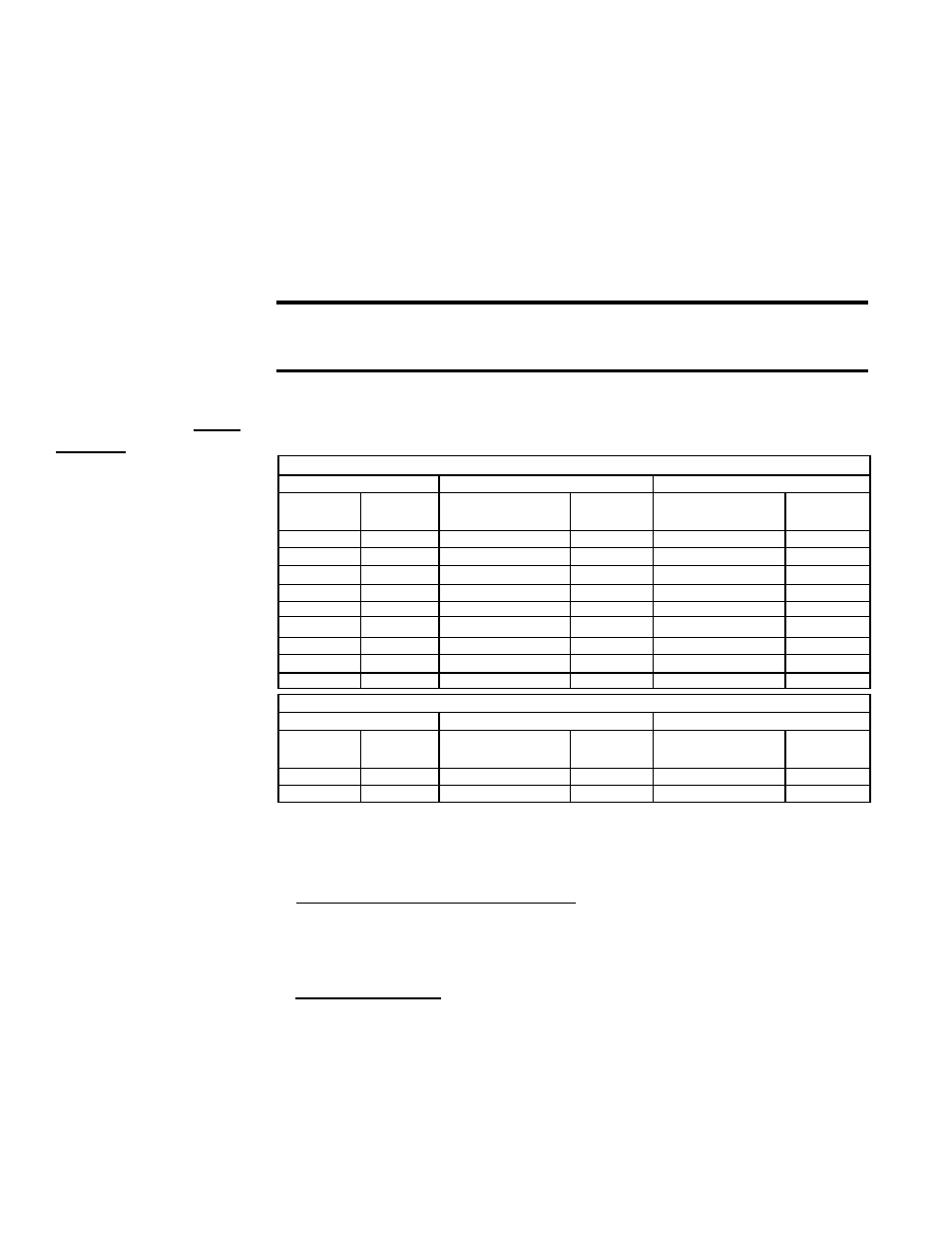

Valve Outlet Pressure Settings by Elevation

This adjustment

can only be done

after the heater is in

operation. High altitude

adjustment is included

in the startup Steps.

NOTE: If elevation is

above 6000 ft (1830M),

a high altitude pressure

switch is required; see

Paragraph 3.2.1.

Manifold Pressure Settings by Altitude for the UNITED STATES

Altitude

Natural Gas (inches w.c.)

Propane Gas (inches w.c.)

Feet

Meters

Single-Stage and

Two-Stage High Fire

Two-Stage

Low Fire

Single-Stage and

Two-Stage High Fire

Two-Stage

Low Fire

0-2000

0-610

3.5

1.8

10.0

5.0

2001-3000

611-915

3.1

1.6

8.8

4.4

3001-4000

916-1220

3.0

1.5

8.5

4.2

4001-5000

1221-1525

2.8

1.5

8.1

4.1

5001-6000

1526-1830

2.7

1.4

7.7

3.9

6001-7000

1831-2135

2.6

1.3

7.4

3.7

7001-8000

2136-2440

2.5

1.3

7.1

3.5

8001-9000

2441-2745

2.4

1.2

6.7

3.4

9001-10000 2746-3045

2.3

1.2

6.7

3.4

Manifold Pressure Settings by Altitude for CANADA

Altitude

Natural Gas (inches w.c.)

Propane Gas (inches w.c.)

Feet

Meters

Single-Stage and

Two-Stage High Fire

Two-Stage

Low Fire

Single-Stage and

Two-Stage High Fire

Two-Stage

Low Fire

0-2000

0-610

3.5

1.8

10.0

5.0

2001-4500

611-1373

2.8

1.5

8.1

4.1

6.0 Mechanical

(cont’d)

6.1 Gas Piping

and Pressures

(cont’d)

is recommended rather than a spring type gauge due to the difficulty of maintaining

calibration of a spring type gauge.

2) Open the manual valve and operate the heater. (NOTE: On a Separated Combus-

tion Model, depress and hold the door safety switch.) Measure the outlet pressure

of the gas valve. To measure low-stage pressure on a unit equipped with a two-

stage valve, disconnect the wire from the “HI” terminal on the valve. (Be sure to

reconnect the wire.)

Normally when operating at sea level, adjustments should not be necessary to the

factory setting. (For high altitude settings, see next paragraph.)

If adjustment is necessary, remove the cap from the adjustment screw(s). Set

pressure to correct settings by turning the regulator screw IN (clockwise) to

increase pressure. Turn regulator screw OUT (counterclockwise) to decrease

pressure.

6.1.2 Valve Outlet

or Orifice Pressure

Setting (cont’d)

CAUTION: DO NOT bottom out the gas valve regulator adjusting screw.

This can result in unregulated manifold pressure causing excess overfire

and heat exchanger failure.