Instructions – Reznor UDAS Unit Installation Manual User Manual

Page 13

Page 13

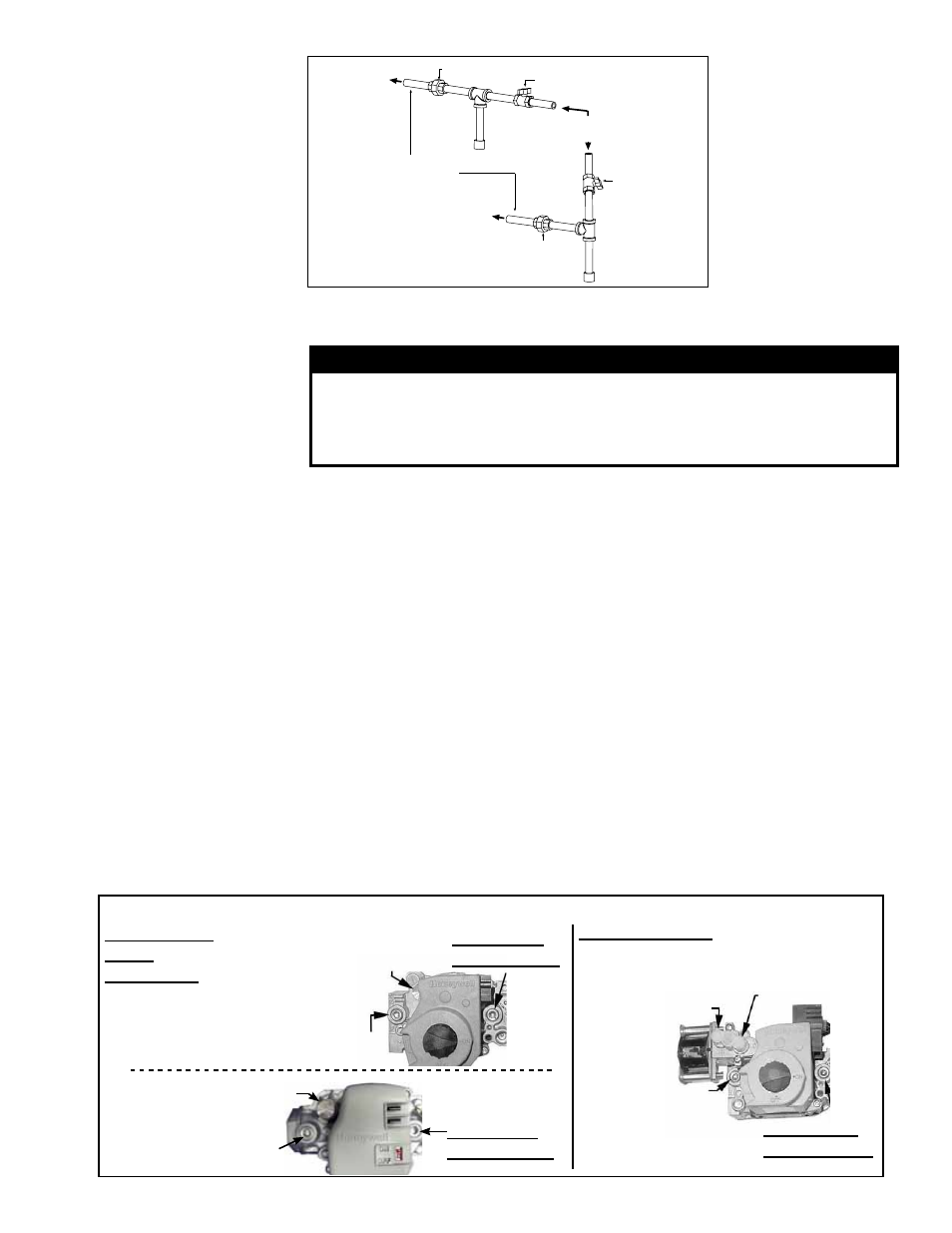

FIGURE 9 - Gas

connection is at

the pipe nipple that

extends outside the

cabinet.

Illustration shows

both a vertical and

horizontal gas supply;

requirements are the

same.

6.1.2 Valve Outlet

or Orifice Pressure

Setting

Measuring valve outlet gas pressure cannot be done until the heater is in operation. It

is included in the steps of the “Check-Test-Start” procedure in Paragraph 9. The follow-

ing warnings and instructions apply.

WARNING

Valve outlet gas pressure must never exceed 3.5” w.c. for natural gas

and 10” w.c. for propane gas. Maximum inlet supply pressure for natu-

ral gas or propane is 14” w.c. Maximum gas pressure can never be

exceded either during operation or static (lock up regulator).

For Natural Gas: When the heater leaves the factory, the combination gas valve is set

so that the valve outlet gas pressure for a single-stage valve or high fire of a two-stage

valve is regulated to 3.5” w.c. Low fire on a two-stage valve is set to 1.8” w.c. Inlet sup-

ply pressure to the valve for natural gas must be a minimum of 5” w.c. or as noted on

the rating plate and a maximum of 14” w.c.

For Propane Gas: When the heater leaves the factory, the combination gas valve is

set so that the valve outlet gas pressure for a single-stage valve or high fire of a two-

stage valve is regulated to 10” w.c. Low fire on a two-stage valve is set to 5.0” w.c.

Inlet supply pressure to the valve for propane gas must be a minimum of 11” w.c. and

a maximum of 14” w.c.

Before attempting to measure or adjust valve outlet gas pressure, the inlet supply

pressure must be within the specified range both when the heater is in operation and

on standby. Incorrect inlet pressure could cause excessive valve outlet gas pressure

immediately or at some future time. If natural gas supply pressure is too high, install a

regulator in the supply line before it reaches the heater. If natural gas supply pressure

is too low, contact your gas supplier.

From Gas Supply

(horizontal or vertical)

Manual shutoff

Pipe nipple extending

outside the cabinet.

Drip

Leg

To Gas Valve

(inside the

cabinet)

To Gas Valve

(inside the

cabinet)

Ground

Joint

Union

Drip

Leg

Ground Joint Union

Manual shutoff

Instructions

NOTE: If operating at high altitude, outlet pressure requires adjustment. Follow

instructions on page 14.

1) Locate the 1/8” output pressure tap on the valve (See FIGURE 10). With the man-

ual valve turned off to prevent flow to the gas valve, connect a manometer to the

1/8” pipe outlet pressure tap in the valve. NOTE: A manometer (fluid-filled gauge)

Check Valve Outlet

Pressure (can only be

done after heater is

operating)

NOTE: Gas Conversion

Kits are available

for changing from

propane gas to natural

gas or natural gas to

propane gas. A factory-

authorized conversion

kit MUST be used.

FIGURE 10 - Top View of Valves showing Outlet Pressure Tap and Adjustment Locations

Single-Stage

Valve

(two styles)

1/8” Outlet

Pressure Tap

Adjust Outlet

Pressure

Inlet

Pressure Tap

Two-Stage Valve

Adjust High

Fire Outlet

Pressure

Adjust Low

Fire Outlet

Pressure

Inlet

Pressure

Tap

1/8” Outlet

Pressure Tap

1/8” Outlet

Pressure Tap

Inlet Pressure Tap

Adjust Outlet Pressure