2 combustion air - standard power vent and, Standard power vent with cv option models 16, Electrical supply and wiring -22 – Reznor UDAS Unit Installation Manual User Manual

Page 16: 1 general, 0 mechanical (cont’d), 0 electrical supply and wiring, 2 combustion air - standard power vent models

Page 16

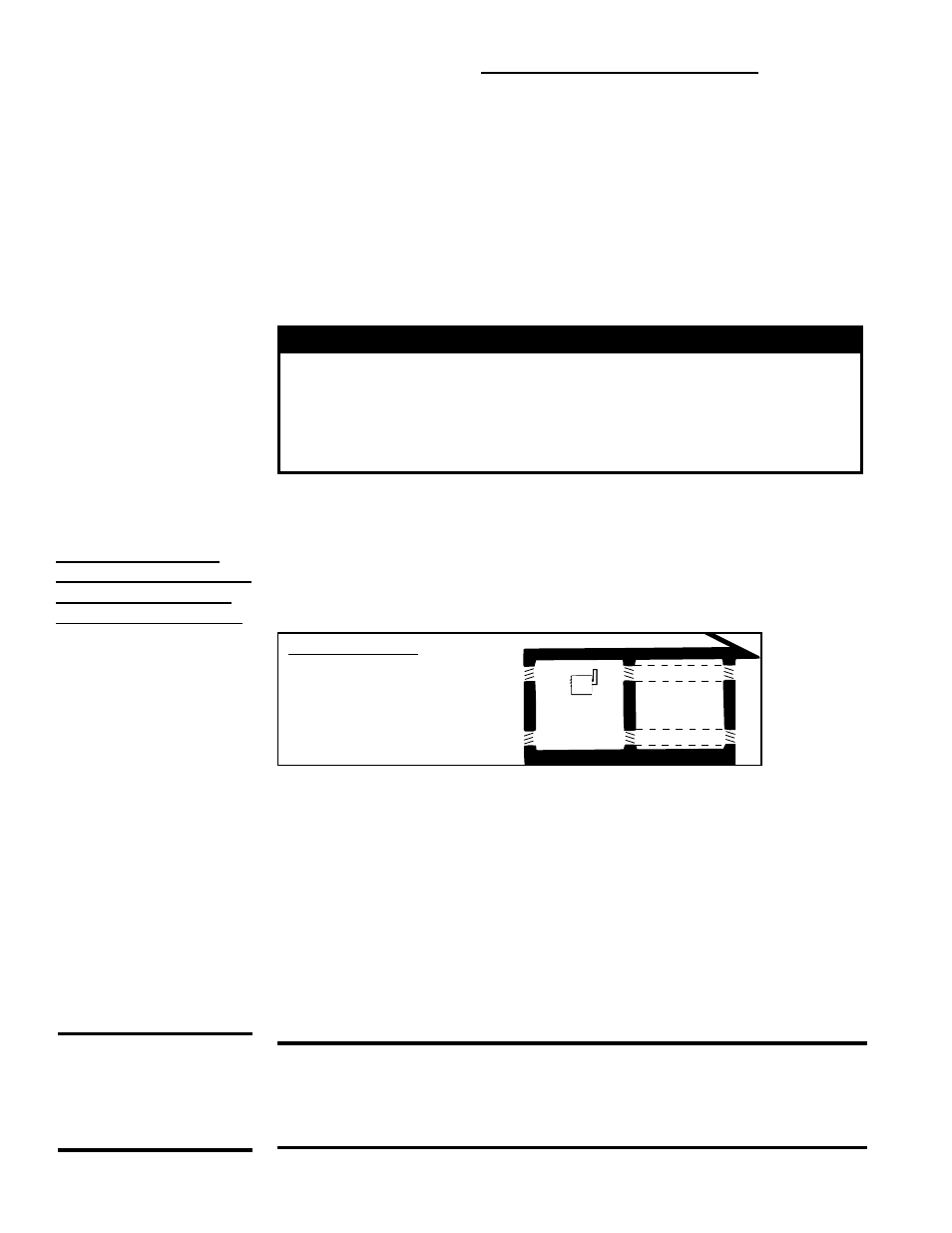

Confined Space:

A space whose volume is

less than 50 cubic feet per

1000 BTUH of the installed

appliance input rating

Combustion Air

Requirements for a

Heater Located in

a Confined Space -

applies to Standard

Power Vent Models and

Standard Power Vent

Models with CV Option

FIGURE 11 - Definition

of Confined Space and

Required Openings for

Combustion Air

(3)

(3)

(1)

(1)

(2)

(2)

Confined

Space

6.2 Combustion Air - Standard Power Vent Models

This heater must be supplied with the air that enters into the combustion process and is

then vented to the outdoors. Sufficient air must enter the equipment location to replace

that exhausted through the heater vent system. In the past, the infiltration of outside air

assumed in heat loss calculations (one air change per hour) was assumed to be suf-

ficient. However, current construction methods using more insulation, vapor barriers,

tighter fitting and gasketed doors and windows, weather-stripping, and/or mechanical

exhaust fans may now require the introduction of outside air through wall openings or

ducts.

The requirements for combustion and ventilation air depend upon whether the unit is

located in a confined or unconfined space. An “unconfined space” is defined as a space

whose volume is not less than 50 cubic feet per 1000 BTUH of the installed appliance.

Under ALL conditions, enough air must be provided to ensure there will not be a

negative pressure condition within the equipment room or space.

WARNING

Standard Power Vent Model unit heaters are designed to take

combustion air from the space in which the unit is installed and

are not designed for connection to outside combustion air intake

ducts. Connecting outside air ducts voids the warranty and could

cause hazardous operation. See Hazard Levels, page 2.

Do not install a unit in a confined space without providing wall openings leading to and

from the space. Provide openings near the floor and ceiling for ventilation and air for

combustion as shown in

FIGURE 11, depending on the combustion air source as noted

in Items 1, 2, and 3 below.

Add total BTUH of all appliances in the confined space and divide by figures below for

square inch free area size of each (top and bottom) opening.

(Note: For Separated

Combustion Model,

see Venting Manual

for combustion air

requirements.)

1. Air from inside the building -- openings 1 square inch free area per 1000 BTUH.

Never less than 100 square inches of free area for each opening. See (1) in

FIGURE 11.

2. Air from outside through duct -- openings 1 square inch free area per 2000

BTUH. See (2) in

FIGURE 11.

3. Air direct from outside -- openings 1 square inch free area per 4000 BTUH. See

(3) in

FIGURE 11.

NOTE: For further details on supplying combustion air to a confined space, see the

National Fuel Gas Code ANSI Z223.1a (latest edition).

6.0 Mechanical

(cont’d)

7.1 General

All electrical wiring and connections, including electrical grounding MUST be made in

accordance with the National Electric Code ANSI/NFPA No. 70 (latest edition) or, in

Canada, with CSA Standard C22.1. In addition, the installer should be aware of any

local ordinances or gas company requirements that might apply.

CAUTION: If any of the original wire as supplied with the appliance must

be replaced, it must be replaced with wiring material having a temperature

rating of at least 105°C, except for limit control, flame rollout, and sensor

lead wires which must be 150°C. See Hazard Levels, page 2.

7.0 Electrical

Supply and

Wiring

CAUTION: Route

wires so that they do

not contact the flue

wrapper or venter

housing.