4 wiring diagrams, 0 electrical supply and wiring (cont’d), Page 18 – Reznor UDAS Unit Installation Manual User Manual

Page 18

Page 18

7.0 Electrical

Supply and

Wiring (cont’d)

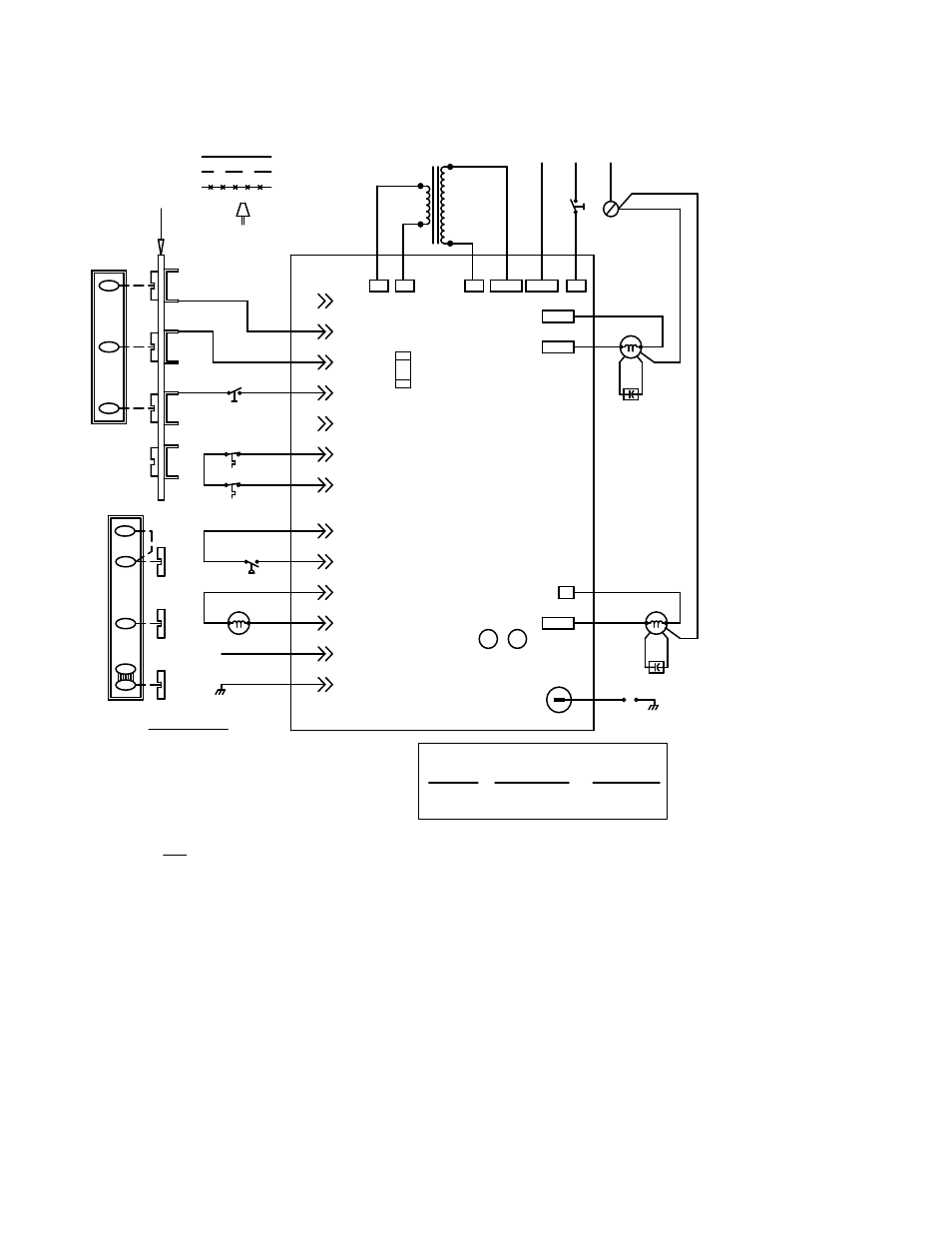

FIGURE 14A - Typical Wiring Diagram for all Single Stage Model or

Recirculation Models

WD# 185139 REV #4

ALL SINGLE STAGE or RECIRCULATION

MODELS

AG1-CL1 or CL22

VENTER

FAN MOTOR

PRESSURE SWITCH

SPARK GAP

GREEN LED

FIELD CONTROL WIRING

150'

250'

350'

75'

125'

175'

#18 GA. WIRE

#16 GA. WIRE

#14 GA. WIRE

TOTAL WIRE

LENGTH

DISTANCE FROM

UNIT TO CONTROL

MIN. RECOMMENDED

WIRE GUAGE

LED

Y

Y

WIRE CONNECTOR

FIELD WIRING

OPTIONAL FACTORY

FACTORY WIRING

DSI CONTROL

FAST FLASH

1 FLASH

2 FLASH

3 FLASH

4 FLASH

STEADY OFF

LED FLASH CODES

NORMAL OPERATION CALL FOR HEAT

IN LOCKOUT FROM FAILED IGNITIONS OR FLAME LOSSES

PRESSURE SWITCH DOES NOT CLOSE WITHIN 30 SECONDS

LIMIT SWITCH OR ROLLOUT SWITCH OPEN

PRESSURE SWITCH IS CLOSED BEFORE VENTER IS ENERGIZED

INTERNAL CONTROL FAULT OR NO POWER

YELLOW LED

FLAME SENSED

STEADY ON

SLOW FLASH WEAK FLAME

UNDESIRED FLAME (VALVE OPEN & NO CALL FOR HEAT)

FAST FLASH

IND BK

NEUTRAL

W

MOTOR

LED

OK

FLAME

G

Y

NEUTRAL

BK

W

LIMIT CONTROL

R

R

R

R

FLAME ROLLOUT

R

BR

FLAME

ELECTRODE

FLAME GROUND

P1-8

P1-3

P1-6

P1-5

P1-7

P1-9

BK

W

GAS VALVE

BL

BR

P1-2

P1-4

BL

24V

115/208/230

Y

BK

BR

R

L1

NEUTRAL NEUTRAL

L1

COM

SEC

SYSTEM TRANSFORMER

EAC/BLO

W

WIRING

OF VENTER ENERGIZED

VOL

T

BK

AT

O

OR A

TC

3.0 AMP

C

R

W

G

Y

R

W1

TERMINAL

STRIP

R

Y

PR

P3-4

P3-3

P3-2

NORMAL OPERATION NO CALL FOR HEAT

STEADY ON

G

G

G

G

G

GRD

SCREW

LINE/1/60

CAPACITOR

(SEE NOTE #6)

CAPACITOR

(SEE NOTE #7)

BR/W

BR

BR

BR/W

SPARK

TRANSFORMER

G

(MODELS 30-125 ONLY)

P3-5

P3-1

WIRING CODE

BLACK - BK

BROWN - BR

RED - R

ORANGE - O

YELLOW - Y

GREEN - G

BLUE - BL

PURPLE - PR

WHITE - W

Y

W

FUSE

(UDAS ONLY)

R

DOOR INTERLOCK

(UDAS ONL

Y)

DISCONNECT

SWITCH

BK

BK

(OPT

CL1) SINGLE ST

AGE

THERMOST

AT

WITH F

AN SWITCH (SET

ANT

. A

T 0.6

AMPS)

R

W

G

WITH F

AN SWITCH (SEE NOTES #8

THRU #10)

(OPT

CL22)

TWO ST

AGE DIGIT

AL

THERMOST

AT

RC

R

R

W2

G

W1

W1

G

W2

OPERATING SEQUENCE

1. SET THERMOSTAT AT LOWEST SETTING, (FAN SWITCH

2. TURN ON MANUAL GAS VALVE.

3. TURN ON POWER TO UNIT.

4. SET THERMOSTAT AT DESIRED SETTING.

5. THERMOSTAT CALLS FOR HEAT, ENERGIZING THE VENTER MOTOR.

6. VENTER PRESSURE SWITCH CLOSES, FIRING UNIT AT FULL RATE.

7. BURNER FLAME IS SENSED, AND IN 30 SECONDS THE FAN

MOTOR IS ENERGIZED.

8. IF THE FLAME IS EXTINGUISHED DURING MAIN BURNER OPERATION,

THE INTEGRATED CONTROL SYSTEM CLOSES THE MAIN VALVE AND

MUST BE RESET BY INTERRUPTING POWER TO THE CONTROL CIRCUIT

(SEE LIGHTING INSTRUCTIONS).

NOTES

1. THE FOLLOWING CONTROLS ARE FIELD INSTALLED OPTIONS: THERMOSTAT

2. DOTTED WIRING INSTALLED BY OTHERS.

3. CAUTION: IF ANY OF THE ORIGINAL WIRING AS SUPPLIED WITH THE

APPLIANCE MUST BE REPLACED, IT MUST BE REPLACED WITH WIRING MATERIAL

HAVING A TEMPERATURE RATING OF AT LEAST 105° C. EXCEPT FOR SENSOR

LEAD WIRE, FLAME ROLLOUT AND LIMIT WIRING WHICH MUST BE 150° C.

4. USE 18 GA. WIRE FOR ALL WIRING ON THE UNIT.

5. LINE AND FAN MOTOR BRANCH WIRE SIZES SHOULD BE OF A SIZE TO PREVENT

VOLTAGE DROPS BEYOND 5% OF SUPPLY LINE VOLTAGE.

6. CAPACITOR IS REMOTE MOUNTED AND INCLUDED ONLY ON 115V MODELS

150-400 AND 208/230V MODELS 100-400.

7. CAPACITOR IS REMOTE MOUNTED AND INCLUDED ONLY ON MODELS 150 - 400.

9. SET FAN SWITCH AT "ON" POSITION FOR CONTINUOUS FAN OPERATION.

AT "AUTO" POSITION.

8. VERIFY JUMPER ON CL22 THERMOSTAT TERMINALS R TO RC.

9. FAN SWITCH OR LOW STAGE OF CL22 THERMOSTAT ENERGIZES THE BLOWER MOTOR.

10. HIGH STAGE OF CL22 THERMOSTAT INITIATES A CALL FOR HEAT.

7.4 Wiring Diagrams