2 application programmes, 1 basic weighing, 2 check weighing – Flintec FT-12 Manual User Manual

Page 15: 3 peak hold, Wt wt+t1 wt+t2 wt-t1 wt-t2

FT-12 Technical Manual, Rev. 1.35 November 2010

Page 15 of 44

6.2 Application

Programmes

Besides basic weighing the FT-12 indicator can be used in different common applications such as check

weighing (over/under), peak hold, dynamic weighing (animal weighing) and automatic filling.

The status LEDs located at the left side of the display and the digital I/O have different meanings according to

the selected application mode. The meanings and the structure of the digital I/O are given in chapter 10.

6.2.1 Basic

Weighing

This is the convenient application mode for general weighing applications. The FT-12 weighing indicator can be

used in both single range and dual range scales. In the basic weighing mode the weight data can be printed on

a label, together with header and footer.

FT-12 has also the capability of totalizing sequential weights, 99 preset tare memories, 99 alphanumerical ID

memories and 9 groups of setpoint memory – each setpoint group has 3 outputs. If an alphanumeric header of

an ID and/or an alphanumeric ID data has been downloaded to FT-12, the alphanumeric name of this ID can

also be printed together with an alphanumeric ID header. Please see the “Memory Operations” in chapter 7 and

the print examples in chapter 9.2.

6.2.2 Check

Weighing

This application mode is used to compare the weight of the load placed on the pan with the predefined target

plus/minus tolerance values. FT-12 can store 9 set point groups, each includes three different set points. In this

way the target and tolerance values for 9 different items can be stored within FT-12 and the selection of these

items can simply be done by keys.

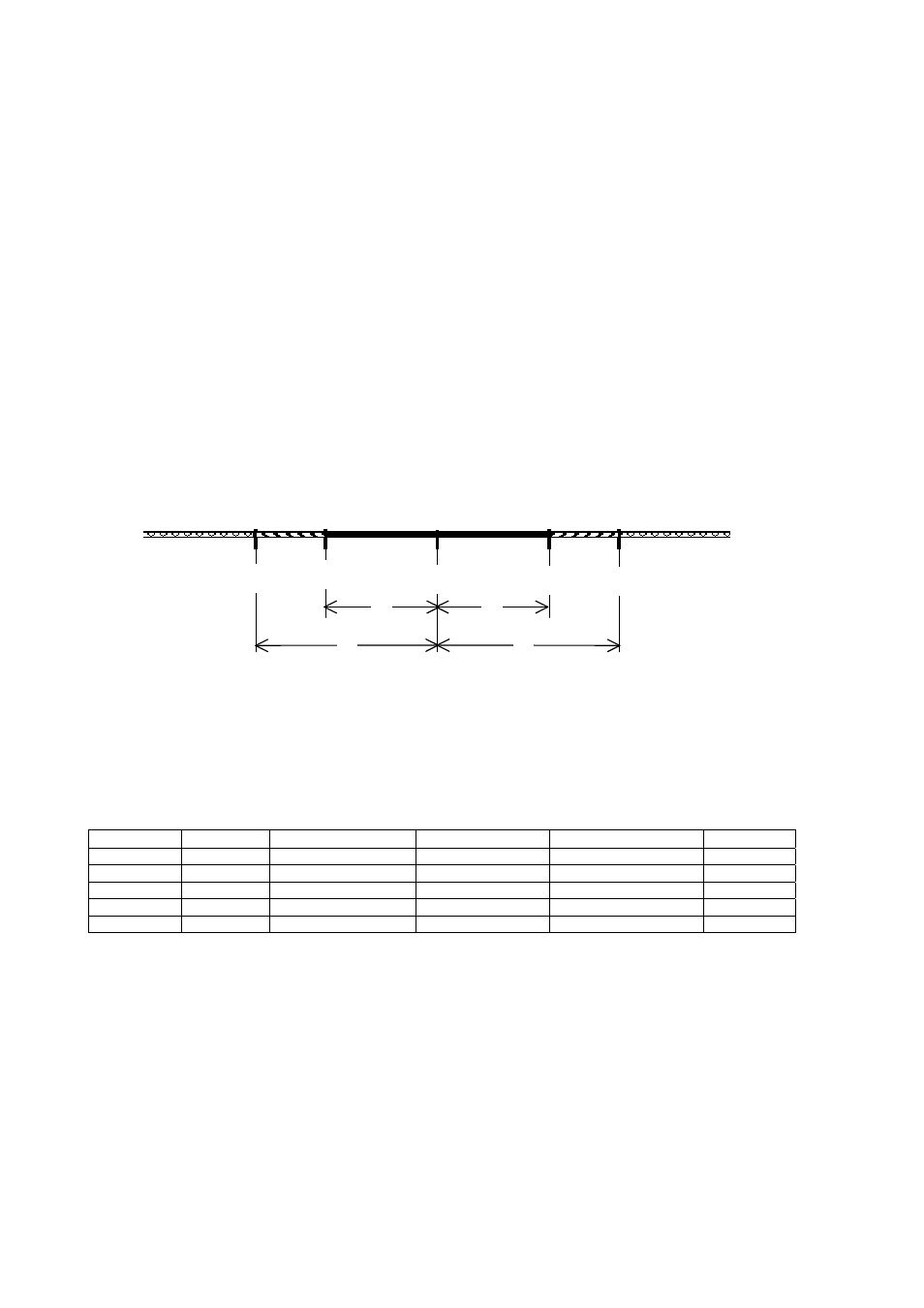

The nominal target value and tolerance data will be entered as given below:

WT (Target weight) = SP1

Tolerance T1 = SP2

Tolerance T2 = SP3

If only one tolerance is needed, so T1 is the right choice (T2 has to be adjusted to a high value respective it has

to be ignored).

In the check weighing mode the weight value must be above a threshold value (parameter [101]) for activating

the outputs. When the weight exceeds the threshold value, the weight monitoring process starts automatically.

The keys are locked and the weighing result is annunciated to the status LEDs and/or digital outputs.

Status LED

G < WT-T2

WT-T2 < G < WT-T1

G = WT+/-T1= OK

WT+T1 < G < WT+T2

G > WT+T2

Input

On

Out1

On

Out2

On

Out3 On

Info On

6.2.3 Peak

Hold

The peak hold mode is generally used in compression, tension and tearing test applications. The force is

monitored and the maximum value is hold on the display. First the threshold value (parameter [101]), the ending

rate (parameter [102]) and the alarm value (parameter [104]) should be defined in the setup mode (see chapter

6.3.6). The peak hold process starts by pressing the

peak hold process is running. Until the force reaches the threshold value (parameter [101]), the message [LoAd]

and the applied force are shown on the display sequentially. In this period the force is not monitored to hold the

peak value. After reaching the threshold value the [LoAd ] message will disappear, the force is now being

monitored and the maximum force value is displayed. If the force decreases more than the rate entered as the

ending rate (parameter [102]) the peak hold process ends. Output no.2 deactivates again. Now output no. 3

activates, which means the peak hold process has finalized. The [PEAK ] message and the peak value are

shown on the display continuously. If the auto print function has been activated (parameter [046] = “1”) the test

result will be automatically printed. The

value entered as alarm value (parameter [104]) the process automatically stops and the [ ovEr] message

WT

WT+T1

WT+T2

WT-T1

WT-T2

T1

T1

T2

T2

OK

W

+

W

++

W-

W--