Build the fin, stabilizer & elevator, Finish the tail surfaces – Dynaflite DYFA1009 User Manual

Page 9

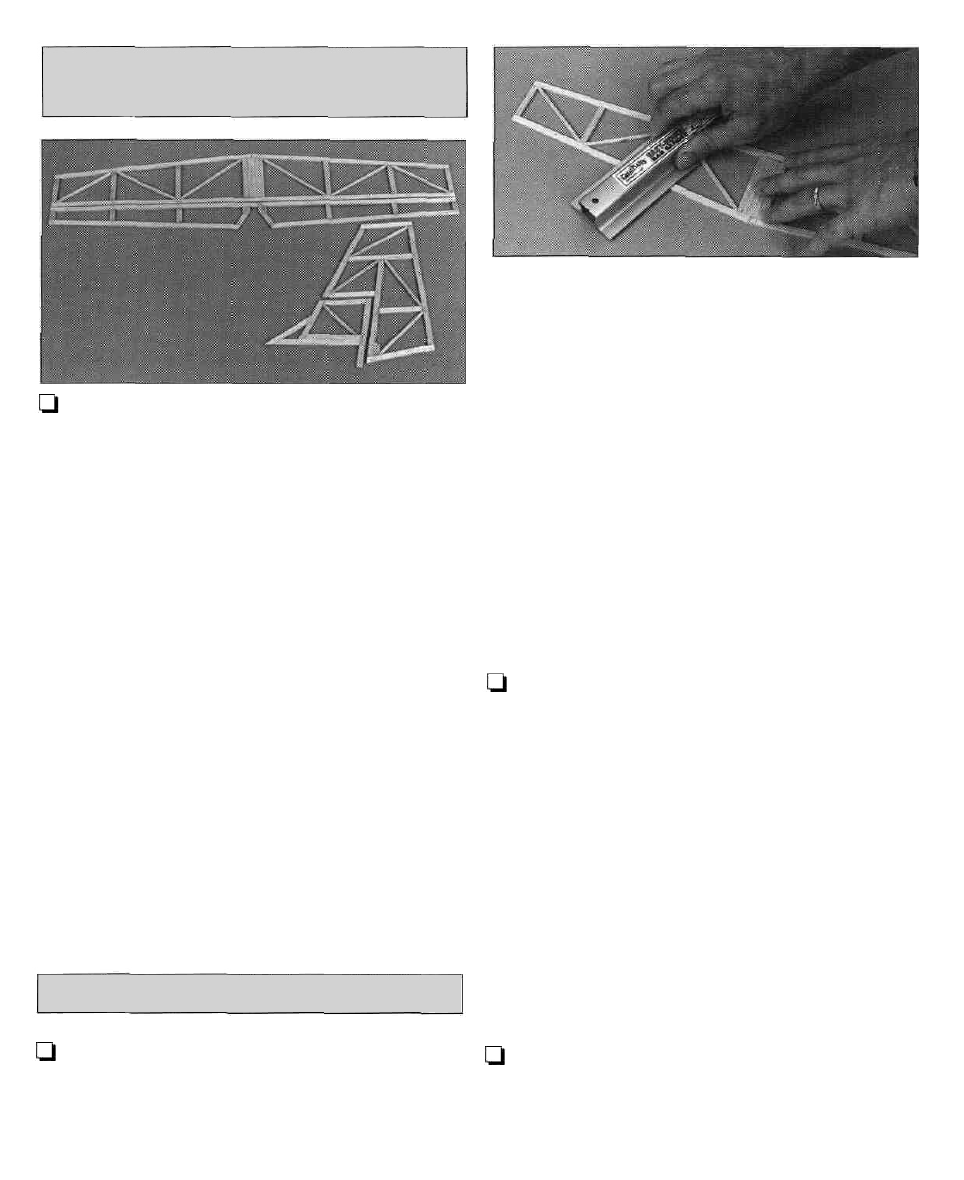

BUILD THE FIN,

STABILIZER & ELEVATOR

Q 1. Use the remainder of the 1/8" x 1/4" balsa

stick plus three more 1 /8" x 1 /4" x 36" balsa sticks,

and the remainder of the 1/8" x 1/8" balsa stick

plus a second 1/8" x 1/8" x 36" balsa stick, to

build the fin, stab and elevator the same way as the

rudder. Remember, where possible it's easier if you

cut the sticks slightly long so you can trim them to

exact length after you remove the assembly from

your building board. After you complete each

assembly, remove it from your building board and

reinforce any glue joints that don't look strong with

medium or thin CA.

Note: Make sure you use the 1/8" x 1/4" x 3-1/2"

basswood stick for the fin trailing edge. Make the

stab center from the 1 /8" x 1" x 2-3/4" balsa sheet.

Cut the angles to match the leading edge first, then

trim the stab center to the length shown on the plan.

A note about sanding "built-up" tail surfaces

:

Use care when you sand a lightweight balsa

structure made up of "sticks." The part flexes and

moves while you sand, and it can be difficult to

keep your sanding block flat so you do not snag

any of the small braces, or over-sand one area

and make it thinner than another. Due to the

design and slow flying speed of the Piece 0' Cake,

a perfectly smooth finish is not necessary. For this

model, the purpose of sanding is just to remove

any glue bumps or uneven edges. Stop sanding

when you have reduced most of the high spots.

Use a large sanding block or a flat bar sander,

and do not apply much pressure while you sand,

Enjoy it's not a racing plane - it's a floater.

Q 2. Use a ballpoint pen to lightly mark the location

of the hinges on the control surfaces where shown

on the plan.

FINISH THE TAIL SURFACES

LJ 1. See the note below/ then use your bar sander

or a sanding block and 220-grit sandpaper to even

the edges and blend the LE's, TE's and "braces" of

all the tail surfaces so they are flat and smooth.

Q 3. Use a hobby knife with a #1 1 blade to

carefully make the hinge slots. The first several cuts

should be just deep enough to make a shallow slit to

establish the hinge slot location.

9