Sheet the top of the fuse – Dynaflite DYFA1009 User Manual

Page 25

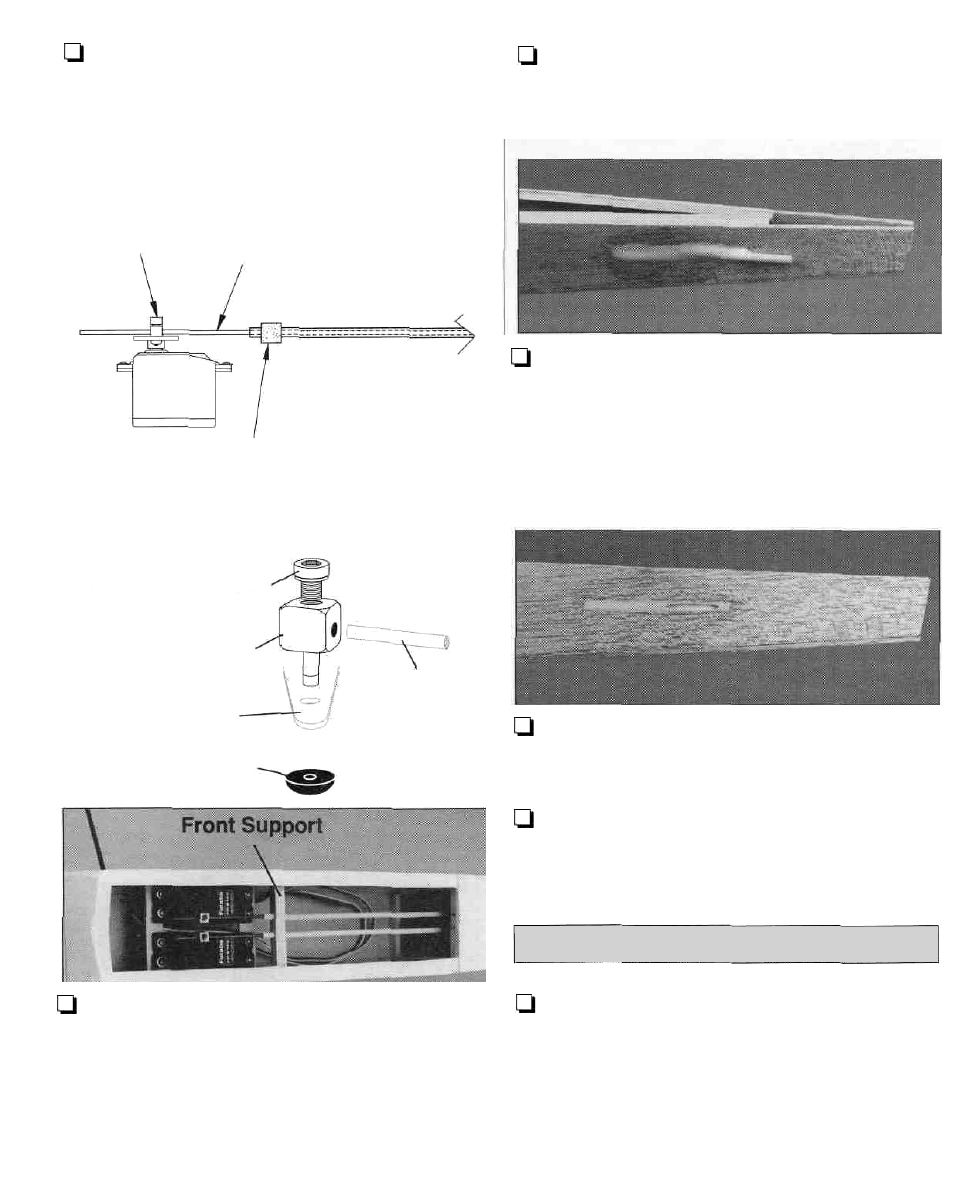

LJ 6. Reinstall, but do not glue, the guide supports in

the fuselage, then cut the 36" outer guide tubes into

two 23" long pieces. Roughen the outside of the guide

tubes with 150-grit sandpaper so glue will stick. Then

slide them through the slots in the back of the fuselage

and route them through the guide supports.

SCREW-LOCK

CONNECTOR

PUSHROD

PUSHROD WIRE

POSITION THE FRONT GUIDE TUBE

SUPPORT SO THE PUSHROD WIRES

ALIGN WITH THE SCREW-LOCK

PUSHROD CONNECTORS.

U 8. Position the aft support so the guide tubes

make a smooth transition from the slots at the back

of the fuselage to the front support. Glue it to the

fuselage sides and F4 with thin CA.

U 7. due the guide tubes to the slots in the back of

the fuselage with microballoons and epoxy.

Microballoons are a powder that you can mix with

epoxy to make a sandable filler where a bond is

required. If you do not have microballoons, glue the

tubes to the fuselage sides with medium CA, then fill

the rest of the slot with HobbyLite filler.

LJ 10. Use your bar sander and 80-grit sandpaper

to sand the guide tubes and filler flush with the

fuselage sides.

U 11. Glue the pushrod guide tubes to the supports

with medium CA.

SHEET THE TOP OF THE FUSE

4-40x1/8" Cap Screw

Pushrod

Pushrod Connector

Servo Arm

Nylon Retainer

Q 7. Insert a Screw-Lock Pushrod Connector in both

servo wheels. Slide the 1/16" x 36" pushrod wires

included with this kit through the guide tubes and

accurately align the front support so the wires pass

through the pushrod connectors. Use thin CA to glue

the front support to the fuselage sides.

CJ 1. Use your bar sander and 80-grit sandpaper to

sand the tops of the fuselage sides and the tops of

the formers so they are even. Clip clothespins to the

top of the fuselage sides in the wing saddle area,

then place a long straightedge such as a metal ruler

on the saddle leaning against the clothespins.

25