Install the servos & pushrod guides – Dynaflite DYFA1009 User Manual

Page 24

LJ 4. Use a large sanding block and 150-grit

sandpaper to sand the triangle pieces, fuselage

sides, fuselage top and fuselage bottom so they are

all flat and even.

Q 5. Glue the 1/8" plywood firewall F1 to the front

of the fuselage with 30-minute epoxy. Use masking

tape to securely hold the firewall to the front of the

fuselage until the epoxy fully cures.

LJ 6. Use your bar sander and 150-grit sandpaper

to sand the edges of the firewall flush with the

fuselage sides, top and bottom.

INSTALL THE SERVOS &

PUSHROD GUIDES

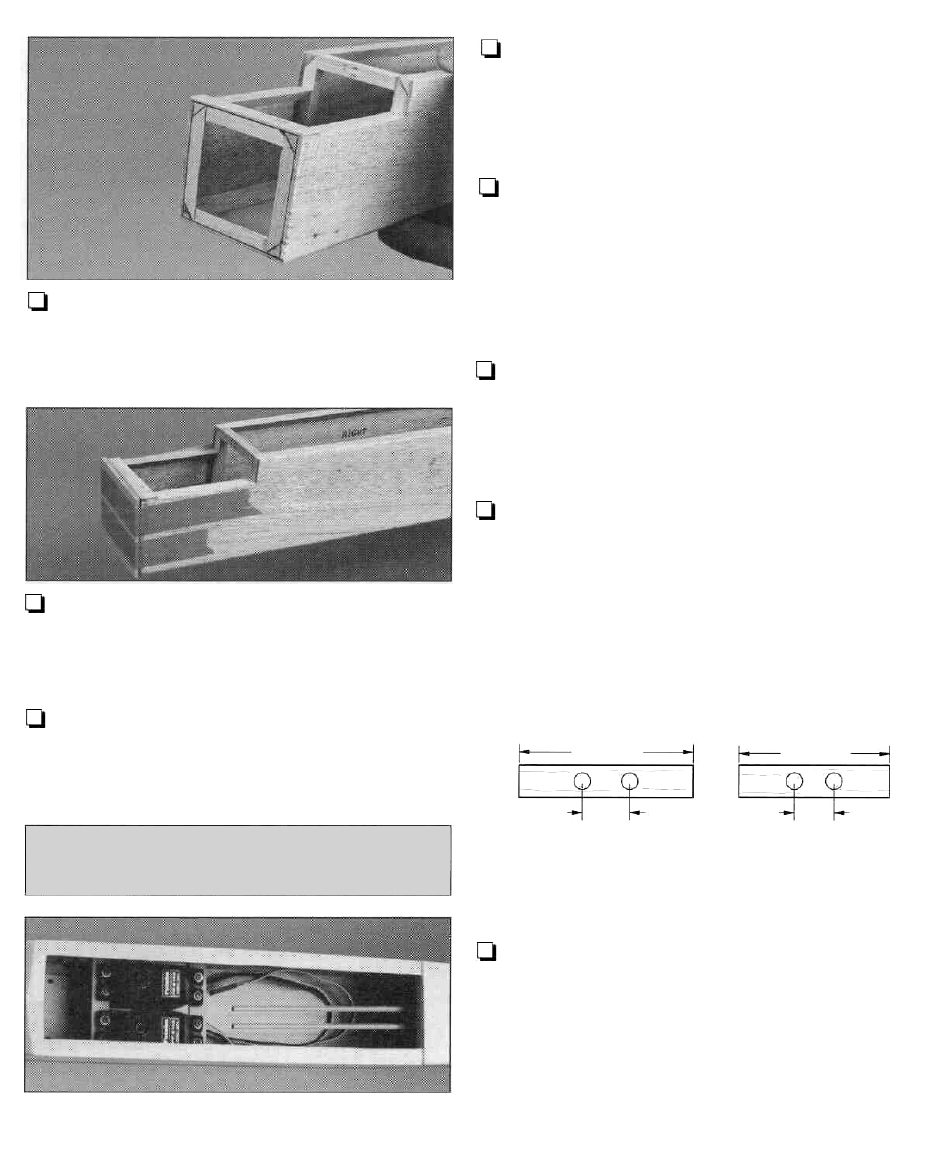

Refer to this photo for the following three steps.

Q 1. Use the 1/8" x 3/8" x 12" plywood stick to

make two servo rails that rest upon the servo rail

supports between the fuselage sides. Fit but do not

glue the servo rails in position, then place your

servos on the rails.

Q 2. Place servo wheels or short servo arms on

your servos, then position the servos so the arms or

wheels will not interfere. Adjust the servo rails so

they are parallel and allow enough space for you to

remove the servos. Carefully (without gluing the

servos to the rails) glue the rails to the rail supports

with medium CA.

Q 3. Remove the servos, then securely glue the rails

to the rail supports and the fuselage sides with

additional medium CA. Reinstall the servos, then drill

1/16" holes through the rails and mount the servos

with the wood screws included with your radio.

Q 4. From the remaining piece of the 1 /4" x 1 /4"

balsa stick, make a forward and an aft pushrod

guide tube support to fit between the fuselage sides

in the location shown on the plan. Test fit the

supports to make sure they are the correct length.

FRONT GUIDE

TUBE SUPPORT

AFT GUIDE

TUBE SUPPORT

TO MATCH

SERVO WHEELS

3/8"

2-1/16"

1-7/16"

MAKE FROM 1/4"

DRILL TWO 9/64"

EVENLY SPACED.

X 1/4" BALSA.

HOLES

Q 5. Drill 9/64" holes through the supports in the

locations shown in the sketch. The holes in the front

support should match the spacing of the holes you will

connect your pushrods to in your servo wheels. If you

do not have a 9/64" drill bit, you may use a 1/8"

drill instead, but insert one of the outer guide tubes in

the holes and spin it around to enlarge the hole so the

guide tubes can slide through a little easier.

24