Carrier 48AJ User Manual

Page 84

84

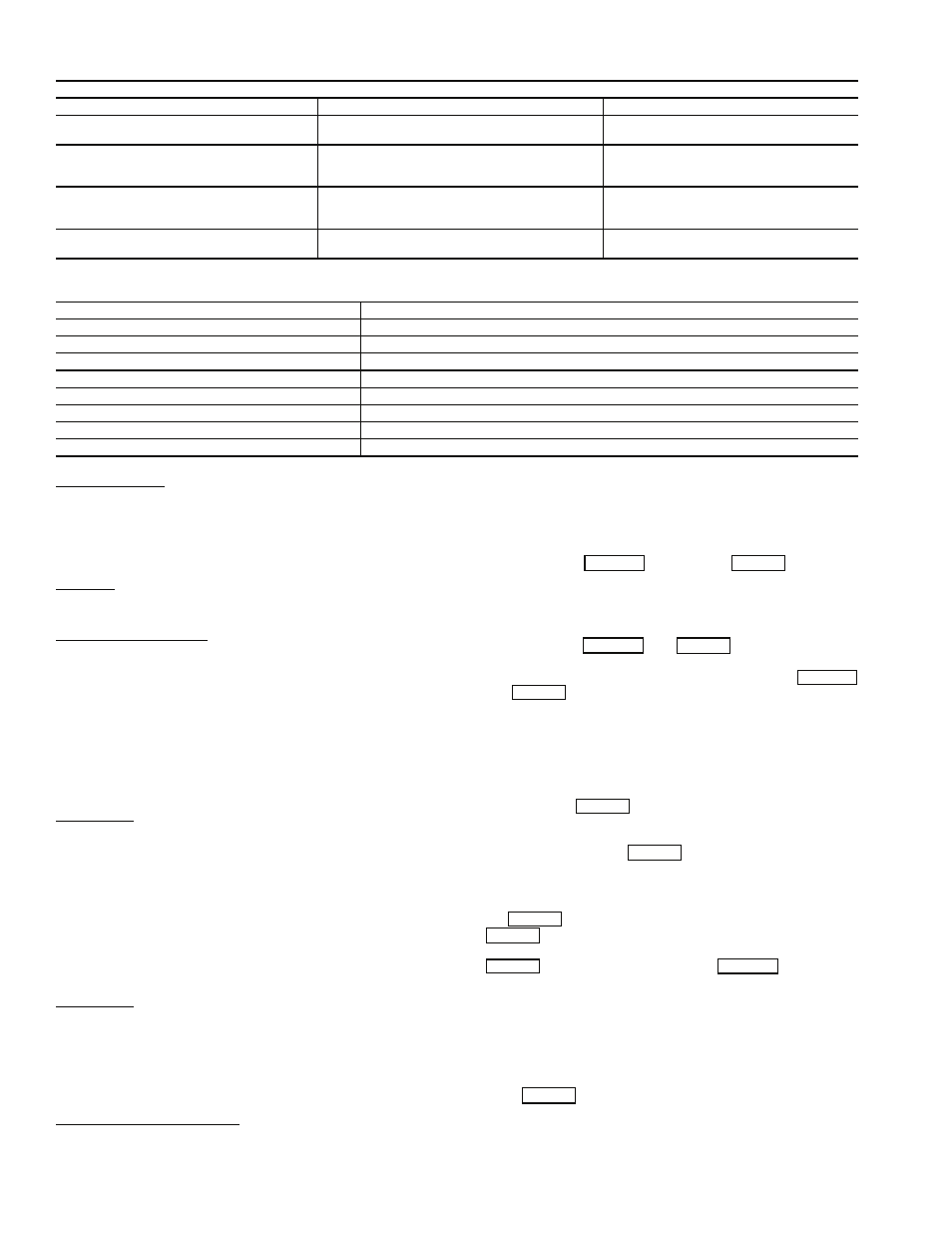

Table 37 — Staged Gas System Components

Table 38 — Stage Gas System Inputs/Outputs

Operating Modes — The SGC will operate the unit in one of

the following operating modes:

• no mode

• Cooling Mode

• Heating1 Mode

• Heating2 Mode

No Mode — In this mode, none of the heat stages are turned

on. No mode occurs if the Cool, Heat or Fan inputs are off or

the Cool input(s) are on.

Tempering (Cool) Mode — In this mode, the SGC tempers in

incoming supply air to maintain the cooling supply air set

point. Tempering mode occurs if the Fan input is ON and all

Cool and Heat inputs are off.

When the SGC determines that the fan is on and the base

unit control is not calling for heat or mechanical cooling, the

SGC will stage heat to maintain the cooling set point which is

set on the CLSASP potentiometer of the SGC. This set point

should be slightly below the supply air set point of the base unit

VAV control. Note that the supply-air temperature will still be

in the “cooling range.”

Heat1 Mode — Heat1 mode is used on VAV applications as

they have one heat stage on the base unit control. CV units

have two heat stages and will not operate under Heat1 mode.

In this mode, heat is staged to control supply air temperature

to HTSASP. Heat1 mode occurs only if Heat1 is ON and Heat2

is OFF and Cool1 and Cool2 are OFF.

When the base unit control calls for first stage of heat, the

SGC will stage heat to maintain the heating set point set on the

potentiometer of the SGC. The HIR will be energized to com-

mand the zone terminals to open to maintain minimum heating

airflow.

Heat2 Mode — Heat2 mode is used on CV applications as

they have 2 heat stages on the base unit control. VAV units

have only 1 heat stage and will not operate under Heat2 mode.

In this mode, when the base unit calls for the second stage

of heat, the SGC will turn on all available heat stages. This

mode only occurs if Heat1 and Heat2 are ON and Cool1 and

Cool2 are OFF.

Accessory Navigator Display — The Navigator Display is a

field-installed accessory. See Fig. 60. Navigator Display is to

be connected to LEN connections at communication board

which is attached to the heating and cooling supply air set point

potentiometers in heating section. The Navigator Display ac-

cessory is required for all units with staged gas control.

The display module provides the user interface to the Staged

Gas control system. See Fig. 60. The display has up and down

arrow keys, an

key, and an

key. These

keys are used to navigate through the different levels of the dis-

play structure. See Table 39. Press the ESCAPE key until the

display is blank to move through the top 11 mode levels indi-

cated by LEDs on the bottom left side of the display.

Pressing the

and

keys simultaneously

will scroll a text description across the display indicating the

full meaning of each display acronym. Pressing the

and

keys when the display is blank (Mode LED lev-

el) will return the display to its default menu of rotating display

items. In addition, the password will be disabled requiring that

it be entered again before changes can be made to password

protected items.

When a specific item is located, the display will flash show-

ing the operator, the item, item value, and then the item units (if

any). Press the

key to stop the display at the item val-

ue. Items in the Configuration and Service Test modes are

password protected. The display will flash PASS and WORD

when required. Use the

and arrow keys to enter the 4

digits of the password. The default password is 1111.

Changing item values or testing outputs is accomplished in

the same manner. Locate and display the desired item. Press

the

key to stop the display at the item value. Press the

key again so that the item value flashes. Use the ar-

row keys to change the value or state of an item and press the

key to accept it. Press the

key and the

item, value, or units display will resume. Repeat the process as

required for other items.

The unit alarms can be cleared through Navigator display.

To check the current alarms, enter the Alarms menu. The first

submenu is the CRNT submenu. The CRNT function displays

the list of current alarms (maximum of 25). The second sub-

menu item is the RCRN (Reset All Current Alarms) function.

Press

to reset the current alarms. The next submenu

item, HIST, displays the list of cleared alarms (maximum of

20). The HIST function can be cleared with the RHIS function.

ITEM

FUNCTION

LOCATION

Heating Controller (SGC)

Logic and Output Relays

Heating section

Supply-Air Thermistors (SAT)

Sense unit leaving-air temperature

Supply duct (factory-provided,

field-installed)

Cooling Supply Air Set Point

Potentiometer (CLSASP)

Specify set point for

tempering heat control

Set Point Range: 35 to 70 F

Heating section, next to SGC

Heating Supply Air Set Point

Potentiometer (HTSASP)

Specify set point for First-Stage

Heating control

Set Point Range: 80 to 125 F

Heating section, next to SGC

Air Flow Switch (AFS)

Prove Supply Fan operation

Fan supply air plenum

(factory-installed)

INPUT

DESCRIPTION

Cool1

Relay in parallel with Compressor #1 contactor

Cool2

Relay in parallel with Compressor #2 contactor

Heat1

24V input from Base Unit control

Heat2

24V input from Base Unit control

Fan

Air proving switch (contact closure on rise in static pressure)

Cool Supply Set Point

Potentiometer, (range 35-70 F)

Heat Supply Set Point

Potentiometer, (range 80-125 F)

Supply Air Thermistor (1, 2 and 3)

Field-installed in supply ductwork (P/N HH79NZ016)

ESCAPE

ENTER

ESCAPE

ENTER

ESCAPE

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ESCAPE

ENTER