Carrier 48AJ User Manual

Page 43

43

Routing Through Bottom of Unit — If wiring is brought in

through bottom of unit, use field-supplied watertight conduit to

run power wiring from basepan out through bottom 3

1

/

2

-in.

hole to the disconnect box and back into unit to the main con-

trol box.

Use strain relief going into control box through 2

1

/

2

-in. di-

ameter hole provided. After wires are in unit control box, con-

nect to power terminal block (see Power Wiring section on

page 33).

Low-voltage wiring must be run in watertight conduit from

the basepan to control box and through

7

/

8

-in. diameter hole

provided in bottom of unit control box. Field-supplied strain re-

lief must be used going into the box. After wiring is in control

box, make connections to proper terminals on terminal blocks

(see Field Control Wiring section on this page).

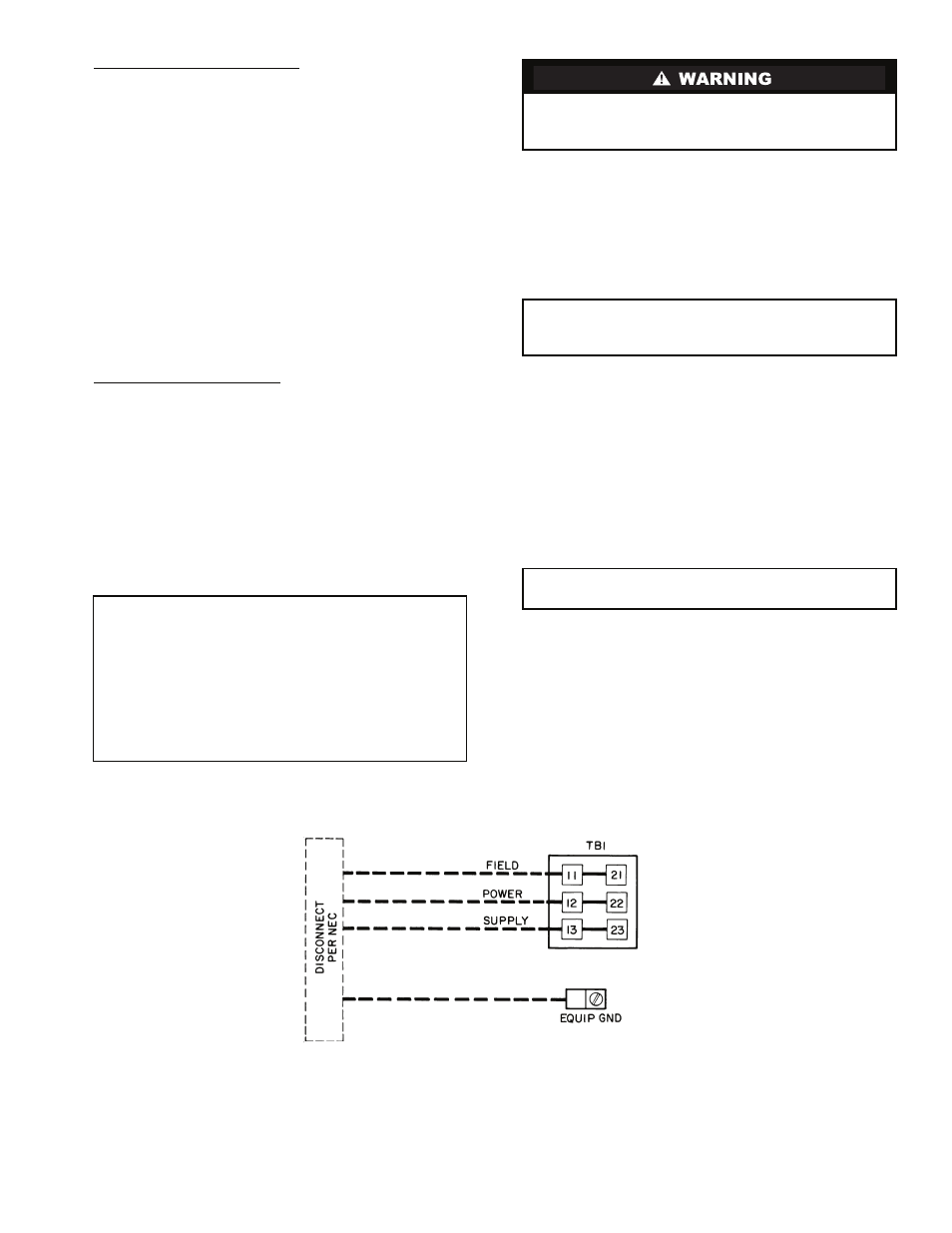

Install conduit connector in unit basepan as shown in

Fig. 5-16. Route power and ground lines through connector to

terminal connections in unit control box as shown on unit wir-

ing diagram and Fig. 28.

Routing Through Side of Unit — Route power wiring in

field-supplied watertight conduit into unit through 2

1

/

2

-in. or

3-in. hole. See Fig. 28.

Use field-supplied strain relief going into control box

through 2

1

/

2

-in. or 3-in. diameter hole provided. After wires are

in unit control box, connect to power terminal block (see Pow-

er Wiring section on page 33).

Bring low-voltage control wiring through factory-drilled

7

/

8

-in. diameter hole in condenser side post. Use strain relief

going into

7

/

8

-in. diameter hole in bottom of unit control box.

After wiring is in control box, make connection to proper

terminals on terminal blocks (see Field Control Wiring section

below).

Affix crankcase heater sticker (located in the installers pack-

et) to unit disconnect switch.

Voltage to compressor terminals during compressor opera-

tion must be within the voltage range indicated on the unit

nameplate. On 3-phase units, phases must be balanced within

2%.

Use the formula in Tables 7 and 8 to determine the percent-

age of voltage imbalance.

Unit failure as a result of operation on improper line voltage

or excessive phase imbalance constitutes abuse and may cause

damage to electrical components.

On 208/230-v units, transformer no. 1 is wired for 230-v. If

208/230-v unit is to be run with 208-v power supply, the trans-

former must be rewired as follows:

1. Remove cap from red (208 v) wire.

2. Remove cap from spliced orange (230 v) wire. Discon-

nect orange wire from black unit power wire.

3. Cap orange wire.

4. Splice red wire and black unit power wire. Cap wires.

FIELD CONTROL WIRING — Install either a Carrier-

approved thermostat or a CCN (Carrier Comfort Network)

compatible temperature sensor. Thermostats are used on CV

(constant volume) units only. Control box diagrams are shown

in Fig. 29-31.

IMPORTANT: The VAV (variable air volume) units use

variable frequency drives, which generate, use and can

radiate radio frequency energy. If units are not installed and

used in accordance with these instructions, they may cause

radio interference. They have been tested and found to

comply with limits of a Class A computing device as

defined by FCC (Federal Communications Commission)

regulations, Subpart J of Part 15, which are designed to

provide reasonable protection against such interference

when operated in a commercial environment.

The unit must be electrically grounded in accordance with

local codes and NEC ANSI/NFPA 70 (National Fire Pro-

tection Association).

IMPORTANT: If the supply voltage phase imbalance is

more than 2%, contact your local electric utility company

immediately.

IMPORTANT: BE CERTAIN UNUSED WIRES ARE

CAPPED. Failure to do so may damage the transformers.

Fig. 28 — Field Power Wiring Connections

LEGEND

GND — Ground

NEC — National Electrical Code

TB

— Terminal Block