11 auxiliary relay contacts, 12 flue gas vent installation, Installation – AERCO BMK 3.0 LN Dual-Fuel Series Gas Fired Low NOx Boiler System User Manual

Page 21

INSTALLATION

2-11

depressed. The fault relay connections are

shown in Figure 2-11.

2.10.12

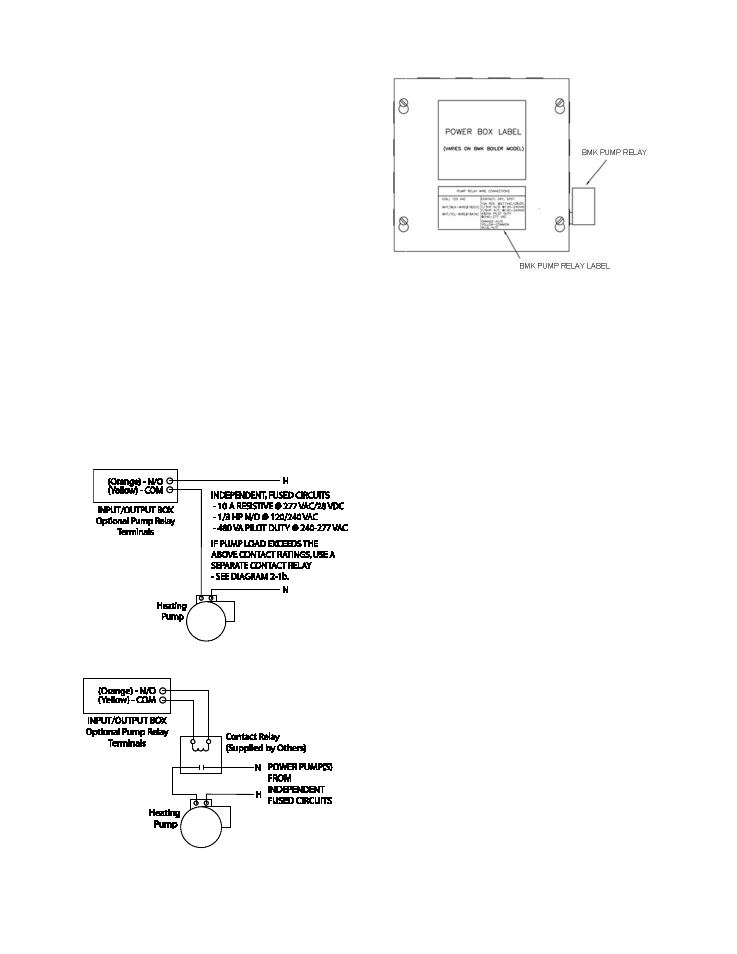

BENCHMARK PUMP RELAY

OPTION

An optional Benchmark pump relay allows the

user to turn a pump on/off and open/close a

motorized valve as the boiler cycles on and off

on demand. The Pump Delay Timer feature

allows the user to keep the pump running and

keep the motorized valve open for up to 30

minutes after the boiler has shut down and the

demand is satisfied.

The Benchmark pump relay (SPDT) contact is

rated for:

•

10 A Resistive @ 277 VAC/28 VDC

•

1/3 HP N/O @ 120/240 VAC

•

1/6 HP N/C @ 120/240 VAC

•

480 VA Pilot Duty @ 240-277 VAC

If pump/valve load exceeds the above contact

ratings, use a separate contact relay.

See Diagrams 2-1a and 2-1b.

To identify if the boiler is equipped with the BMK

Pump Relay Option (part no. 69102), look for the

label and relay as shown in Figure 2-12.

Diagram 2-1a: Schematic – System Pump

Start using Boiler Pump Relay

Diagram 2-1b: Schematic – System Pump

Start using a Separate Contact Relay

Figure 2-12: Identifying the Presence of BMK

Pump Relay Option 69102

2.11 AUXILIARY RELAY CONTACTS

Each Boiler is equipped with a single pole

double throw (SPDT) relay that is energized

when there is a demand for heat and de-

energized after the demand for heat is satisfied.

The relay is provided for the control of auxiliary

equipment, such as pumps and louvers, or can

be used as a Boiler status indictor (firing or not

firing). Its contacts are rated for 120 VAC @ 5

amps. Refer to Figure 2-11 to locate the AUX

RELAY terminals for wiring connections.

2.12 FLUE GAS VENT INSTALLATION

The minimum allowable vent diameter for a

single Benchmark 3.0 Dual-Fuel Boiler is 8

inches.

The AERCO Benchmark Venting and

Combustion Air Guide, GF-2050, must be

consulted before any flue gas vent or inlet air

venting is designed or installed. U/L listed,

positive pressure, watertight vent materials as

specified in AERCO’s GF-2050, must be used

for safety and code compliance. Since the unit is

capable of discharging low temperature exhaust

gases, horizontal sections of the flue vent

system must be pitched back to the unit a

minimum of 1/4 inch per foot to avoid

condensate pooling and allow for proper

drainage.

The combined pressure drop of vent and

combustion air systems must not exceed 140

equivalent feet of 8 inch ducting. Fittings as well

as pipe lengths must be calculated as part of the

equivalent length.

For a natural draft installation the draft must not

exceed ±0.25 inch W.C. These factors must be

planned into the vent installation. If the

maximum allowable equivalent lengths of piping

are exceeded, the unit will not operate properly

or reliably.