2 setting the unit, Installation – AERCO BMK 3.0 LN Dual-Fuel Series Gas Fired Low NOx Boiler System User Manual

Page 12

INSTALLATION

2-2

43"

24"

24"

24"

4" HIGH PAD

REAR

FRONT

77"

18"

101"

79"

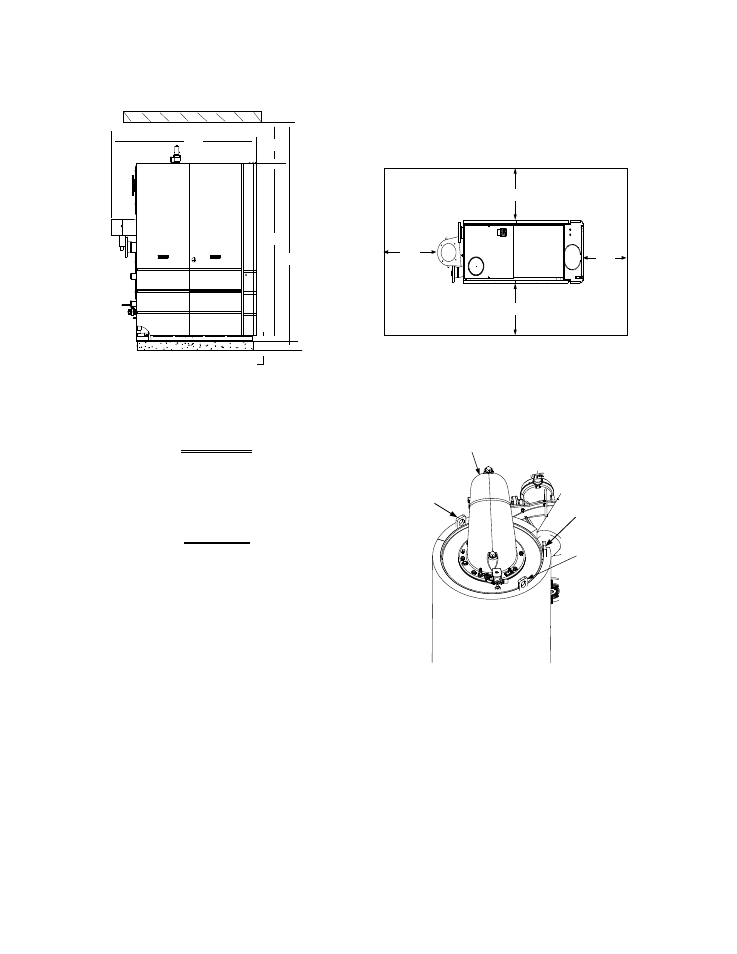

Figure 2-1 Benchmark 3.0 Dual Fuel Boiler Clearances

WARNING

KEEP THE UNIT AREA CLEAR AND

FREE FROM ALL COMBUSTIBLE

MATERIALS AND FLAMMABLE

VAPORS OR LIQUIDS

.

CAUTION

While packaged in the shipping

container, the boiler must be moved

by pallet jack or forklift from the

FRONT ONLY.

2.4.2 Setting the Unit

The unit must be installed on a 4 inch to 6 inch

housekeeping pad to ensure proper condensate

drainage. If anchoring the unit, refer to the

dimensional drawings in Appendix F for anchor

locations. A total of 3 lifting tabs are provided at

the top of the primary heat exchanger as shown

in Figure 2-2. However, USE ONLY TABS 1

AND 2 SHOWN IN FIGURE 2-2 TO MOVE THE

ENTIRE UNIT. Tabs 1 and 3 are used only

when removing or replacing the unit’s primary

heat exchanger. Remove the front top panel

from the unit to provide access to the lifting tabs.

Remove the four (4) lag screws securing the unit

to the shipping skid. Lift the unit off the shipping

skid and position it on the 4 inch to 6 inch

housekeeping concrete pad (required) in the

desired location.

PRIMARY HEAT

EXCHANGER

LIFTING

TAB 2

LIFTING

TAB 1

BURNER

ASSEMBLY

LIFTING

TAB 3

Figure 2-2

Lifting Lug Locations

In multiple unit installations, it is important to

plan the position of each unit in advance.

Sufficient space for piping connections and

future service/maintenance requirements must

also be taken into consideration. All piping must

include ample provisions for expansion

.

If installing a Combination Control Panel (CCP)

system, it is important to identify the

Combination Mode Boilers in advance and place

them in the proper physical location. Refer to

Chapter 5 for information on Combination Mode

Boilers.