Benchmark 2.0ln dual-fuel low nox boiler, Gf-127 – AERCO BMK 2.0 LN Dual Fuel Serial G-11-2402 and UP User Manual

Page 46

CHAPTER 4: INITIAL START-UP

Page 46 of 160 PR2: 04/22/13

Benchmark 2.0LN Dual-Fuel Low NOx Boiler

Operation and Maintenance Manual

OMM-0052_0E

GF-127

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288

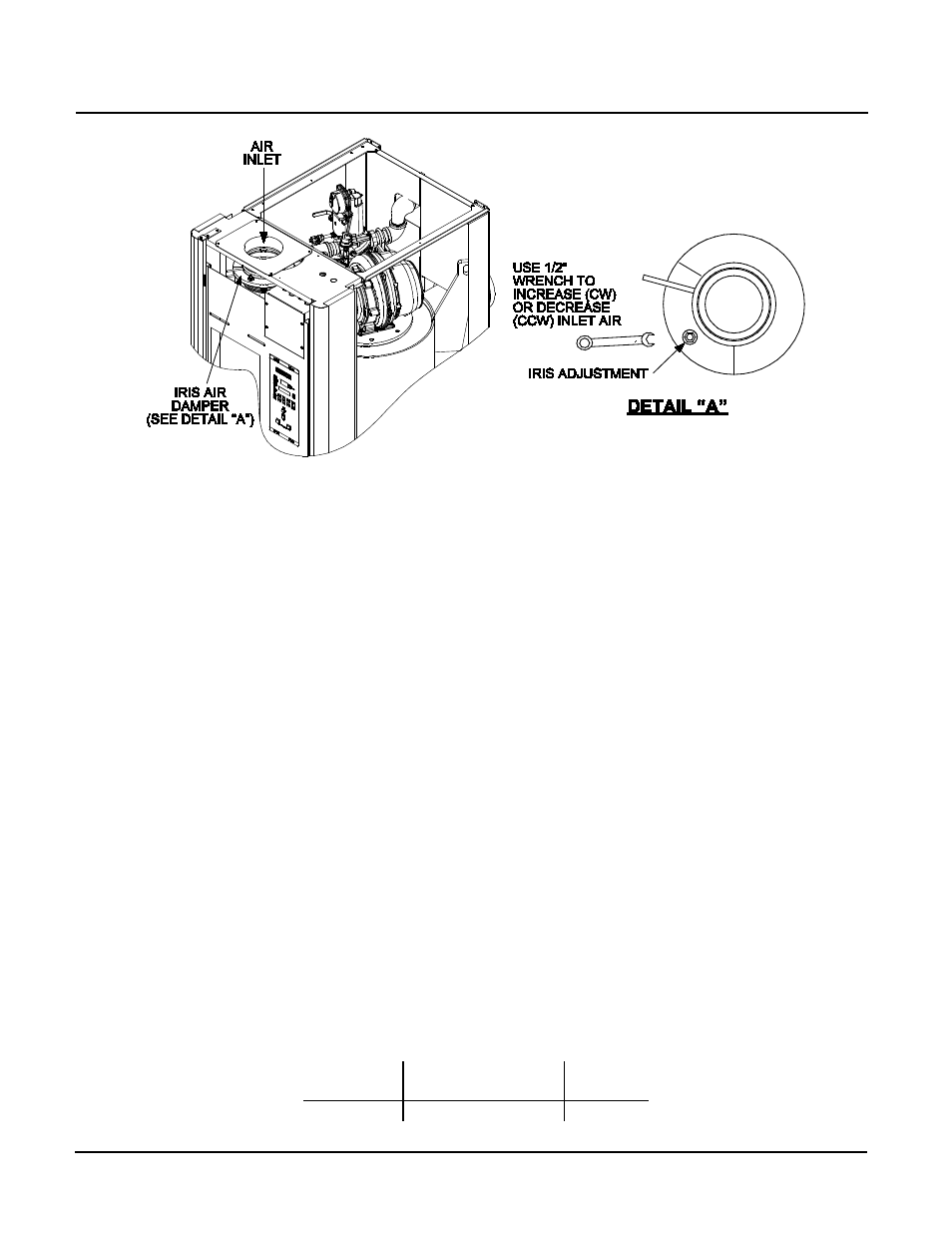

Figure 4-5: Iris Air Damper Location/Adjustment

NOTE

The remaining combustion calibration steps are performed using

the Combustion Cal Menu included in the C-More Control System.

The combustion calibration control functions will be used to adjust

the oxygen level (%) at valve positions of 80%, 60%, 45%, 30%

and 20% as described in the following steps. These steps assume

that the inlet air temperature is within the range of 50°F to 100°F.

17. Press the MENU key on the front panel of the C-MORE and access the Setup menu.

Enter password 6817 and then press the ENTER key.

18. Press the MENU key on the front panel of the C-MORE until Combustion Cal Menu

appears on the C-More display.

19.

Press the ▲ arrow key until SET Valve Position appears on the C-MORE display.

20. Press the CHANGE key. SET Valve Position will begin to flash.

21.

Press the ▲ arrow key until the SET Valve Position reads 80%. Press the ENTER key.

22.

Next, press the down (▼) arrow key until CAL Voltage 80% is displayed.

23. Press the CHANGE key and observe that CAL Voltage 80% is flashing.

24. The oxygen level at the 80% valve position should be as shown below. Also, ensure that

the carbon monoxide (CO) and nitrogen oxide (NOx) readings do not exceed the values

shown.

Table 4-2: Combustion Oxygen Levels for a

80%

Air/Fuel Valve Position

Oxygen %

± 0.2

Carbon Monoxide

NOx

6.0 %

<100 ppm

<20 ppm