3 natural gas combustion calibration, Benchmark 2.0ln dual-fuel low nox boiler, Gf-127 – AERCO BMK 2.0 LN Dual Fuel Serial G-11-2402 and UP User Manual

Page 44

CHAPTER 4: INITIAL START-UP

Page 44 of 160 PR2: 04/22/13

Benchmark 2.0LN Dual-Fuel Low NOx Boiler

Operation and Maintenance Manual

OMM-0052_0E

GF-127

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288

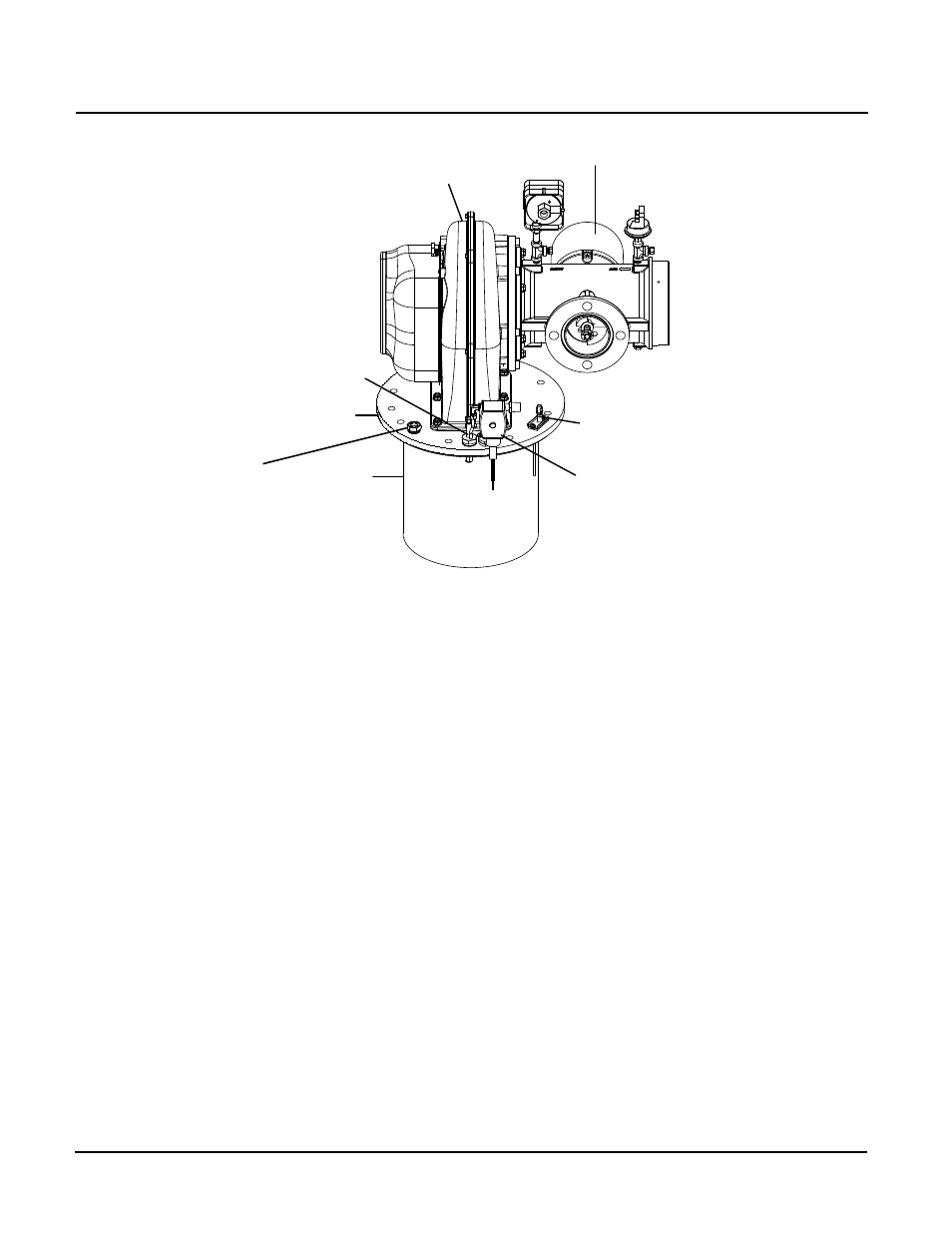

AIR/FUEL

VALVE

STAGED

IGNITION

ASSEMBLY

FLAME

DETECTOR

IGNITOR-

INJECTOR

BLOWER

BURNER

PLATE

BURNER

Figure 4-3: Flame Observation Port Location

4.3 NATURAL GAS COMBUSTION CALIBRATION

The Benchmark 2.0LN Dual-Fuel Boiler is combustion calibrated at the factory prior to shipping.

However, recalibration as part of initial start-up is necessary due to changes in the local altitude,

gas BTU content, gas supply piping and supply regulators. Factory Test Data sheets are

shipped with each unit. These sheets must be filled out and returned to AERCO for proper

Warranty Validation.

It is important to perform the following procedure as outlined. This will keep readjustments to a

minimum and provide optimum performance.

1. Open the water supply and return valves to the unit and ensure that the system pumps

are running.

2. Open the natural gas supply valve(s) to the unit.

3. Set the control panel ON/OFF switch to the OFF position.

4. Turn on external AC power to the unit. The display will show LOSS OF POWER and the

time and date.

5. Set the unit to the Manual Mode by pressing the AUTO/MAN key. A flashing Manual

Valve Position message will be displayed with the present rate in %. Also, the MANUAL

LED will light.

6. Adjust the air/fuel valve position to 0% by pressing the

▼ arrow key.

7. Ensure that the leak detection ball valve down-stream of the SSOV is open (Figure 4-1).

8. Ensure that the Fuel Selector Switch (Figure 4-5) is in the NATURAL GAS position.

Flame

Observation

Port