9 modes of operation and field control wiring, 1 constant setpoint mode, Benchmark 2.0ln dual-fuel low nox boiler – AERCO BMK 2.0 LN Dual Fuel Serial G-11-2402 and UP User Manual

Page 19: Gf-127

CHAPTER 2: INSTALLATION

PR2: 04/22/13 Page 19 of 160

Benchmark 2.0LN Dual-Fuel Low NOx Boiler

Operation and Maintenance Manual

OMM-0052_0E

GF-127

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288

GND

NEU

L1

120 VAC, 1 PHASE

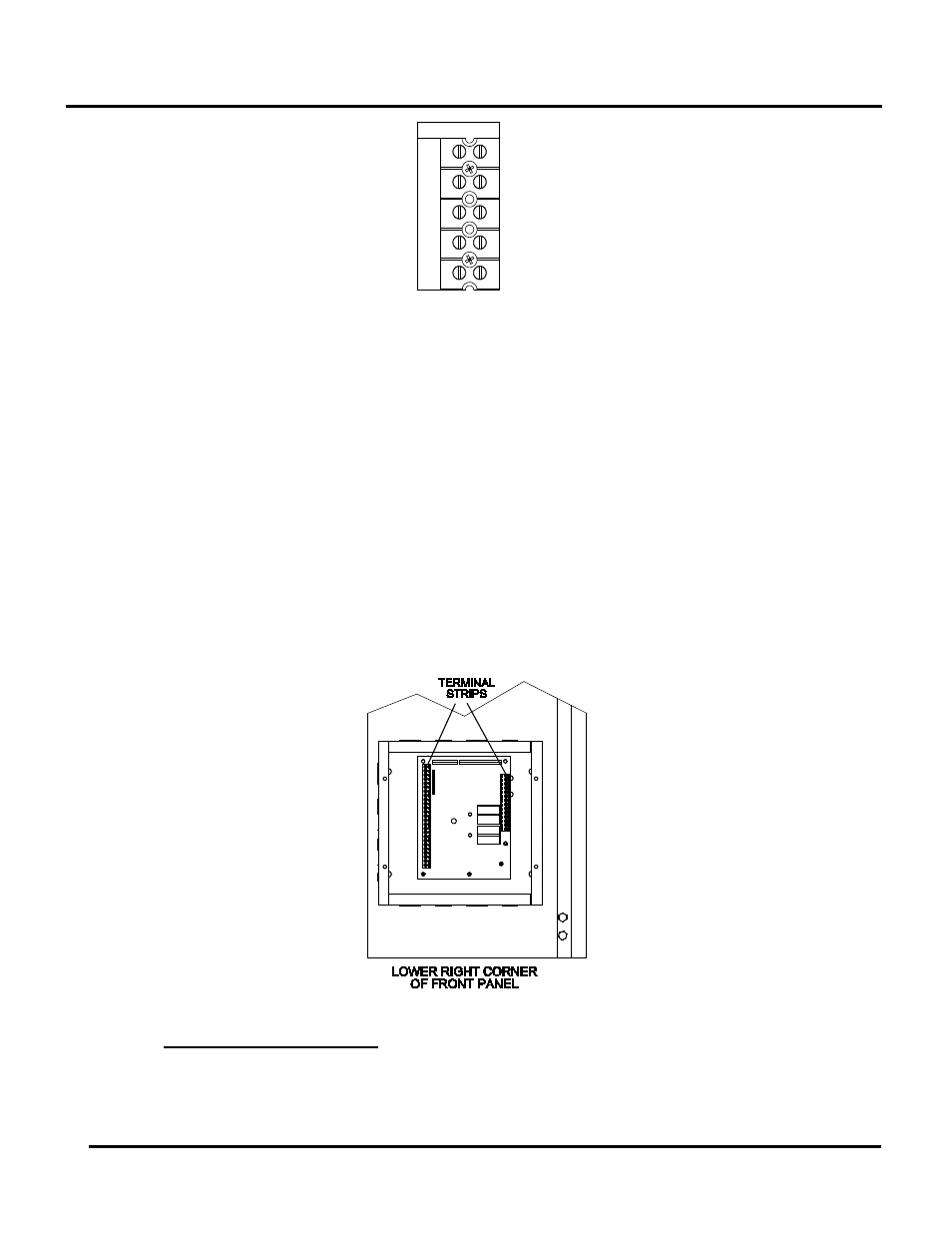

Figure 2-8: AC Terminal Block Configurations

2.9 MODES OF OPERATION AND FIELD CONTROL WIRING

The Benchmark 2.0 Boiler is available in several different modes of operation. While each unit

is factory configured and wired for its intended mode, some additional field wiring may be

required to complete the installation. This wiring is typically connected to the Input/Output (I/O)

Box located on the lower portion of the unit front panel (Figure 2-9) behind the removable front

door.

To access the I/O Box terminal strips shown in Figure 2-9, loosen the four cover screws and

remove the cover. All field wiring is installed from the rear of the panel by routing the wires

through one of the four bushings provided.

Refer to the wiring diagram provided on the cover of the I/O Box when making all wiring

connections.

Brief descriptions of each mode of operation, and their wiring requirements, are provided in the

following paragraphs. Additional information concerning field wiring is provided in paragraphs

2.10.1 through 2.10.13. Refer to Chapter 5 for detailed information on the available modes of

operation.

Figure 2-9: Input/Output (I/O) Box Location

Constant Setpoint Mode

2.9.1

The Constant Setpoint Mode is used when it is desired to have a fixed setpoint that does not

deviate. No wiring connections, other than AC electrical power connections, are required for

this mode. However, if desired, fault monitoring or enable/disable interlock wiring can be

utilized (see paragraphs 2.10.11.1 and 2.10.11.2).