10 start/stop levels, Control panel operating procedures – AERCO BMK 2.0 LN Nat. Gas June 2010 User Manual

Page 34

CONTROL PANEL OPERATING PROCEDURES

3-10

8. With the unit firing properly, it will be

controlled by the temperature controller

circuitry. The boiler’s VALVE POSITION will

be continuously displayed on the front panel

bargraph.

Once the demand for heat has been satisfied,

the Control Box will turn off the dual SSOV gas

valves. The blower relay will be deactivated and

the Air/Fuel Valve will be closed. Standby will

be displayed.

3.10 START/STOP LEVELS

The start and stop levels are the Air/Fuel Valve

positions (% open) that start and stop the unit,

based on load. These levels are Factory preset

as follows:

Start Level: 22%

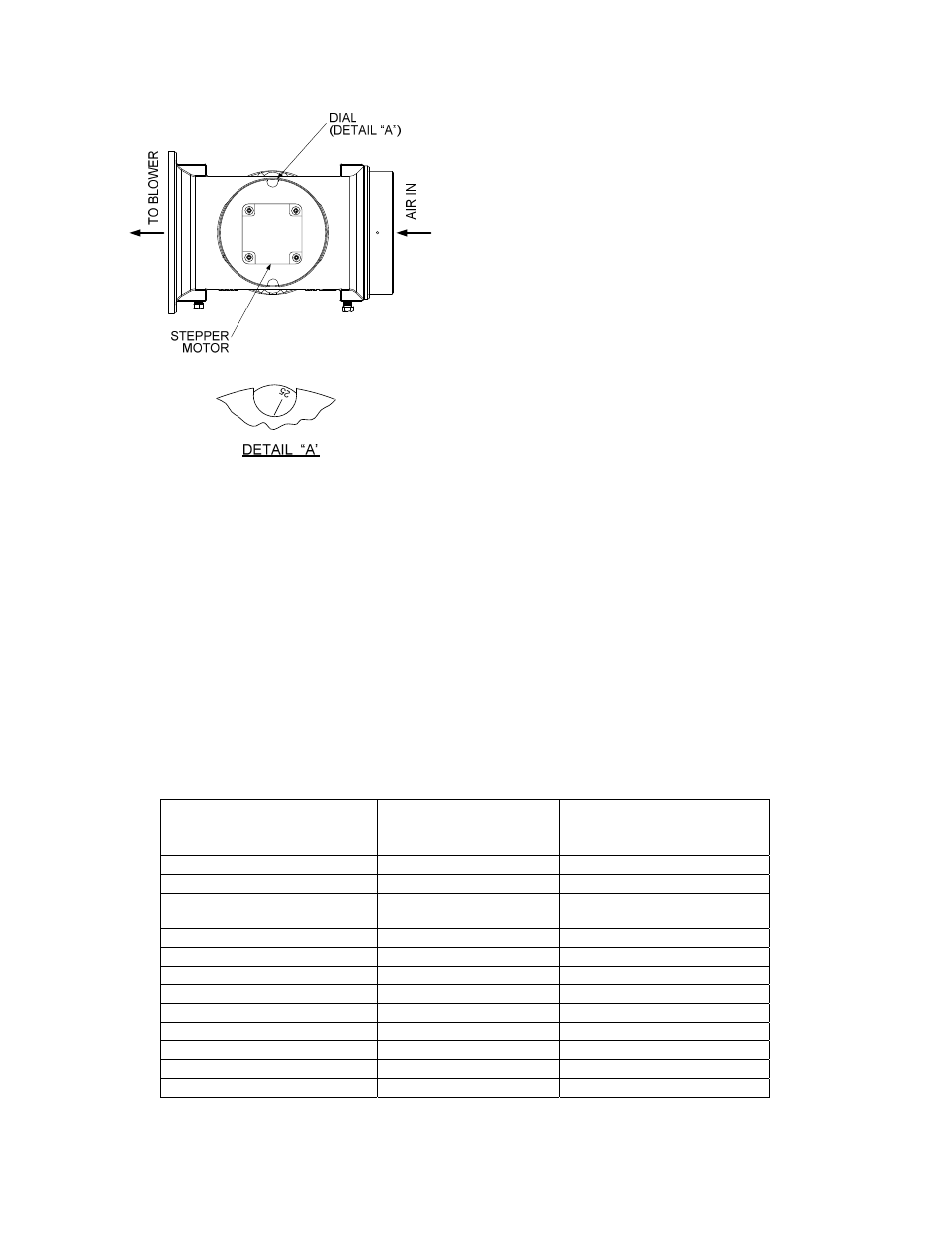

Figure 3-6.

Air/Fuel Valve In Ignition Position

Stop Level: 18%

Normally, these settings should not require

adjustment.

6. Up to 7 seconds will be allowed for ignition

to be detected. The igniter relay will be

turned off one second after flame is

detected.

Note that the energy input of the boiler is not

linearly related to the Air/Fuel Valve position.

Refer to Table 3-7 on the following page for the

relationship between the energy input and valve

open position (%) for a unit running on natural

gas.

7. After 2 seconds of continuous flame, Flame

Proven

will be displayed and the flame

strength will be indicated. After 5 seconds,

the current date and time will be displayed in

place of the flame strength.

Table 3-7.

Relationship Between Air/Fuel Valve Position and Energy Input For Unit Running On Natural Gas

Air/Fuel Valve Position

(% Open)

Energy Input

(BTU/Hr)

Boiler Energy Input

(% of Full Capacity)

0 0 0

10% 0 0

18%

(Stop Level)

100,000

5.0%

20% 202,000 10%

30% 428,000 21%

40% 705,000 35%

50% 956,000 48%

60% 1,390,000 70%

70% 1,770,000 89%

80% 1,890,000 95%

90% 1,960,000 98%

100% 2,000,000 100%