Troubleshooting – AERCO BMK 1.5 LN Dual Fuel Jan 2009 User Manual

Page 61

TROUBLESHOOTING

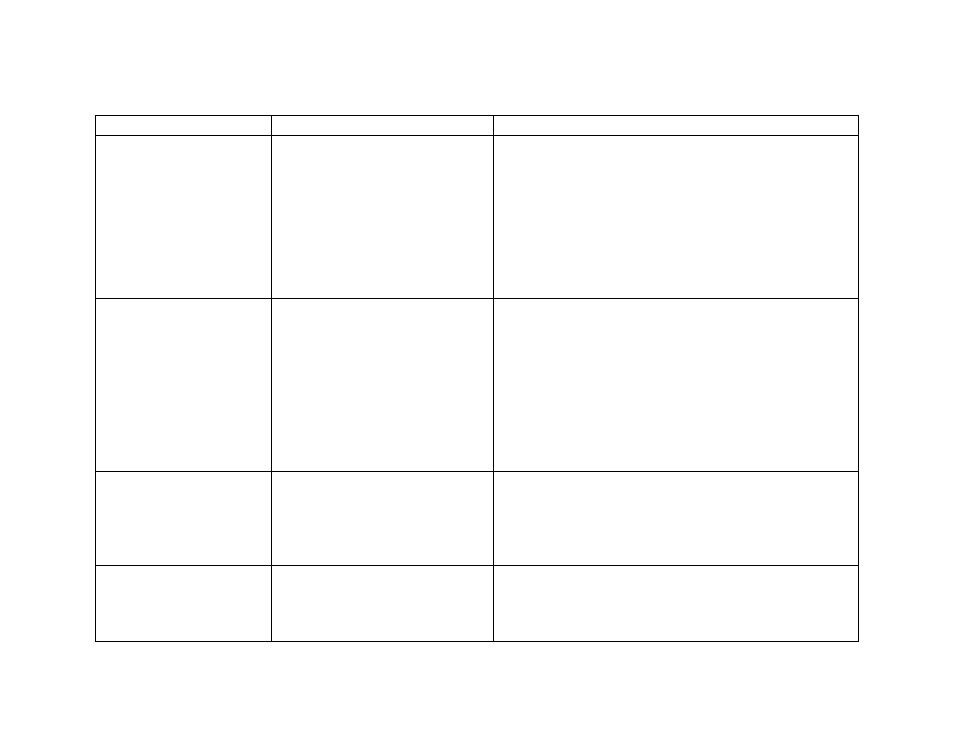

TABLE 8-1. BOILER TROUBLESHOOTING – Continued

FAULT INDICATION

PROBABLE CAUSES

CORRECTIVE ACTION

(continued)

7. Defective SSOV

8. Defective differential pressure

regulator..

9. Carbon or other debris on burner.

7. While externally arcing the spark ignitor, observe the

open/close indicator in the Safety Shut-Off Valve to ensure it is

opening. If the valve does not open, check for 120VAC at the

valves input terminals. If 120VAC is not present, the IGST

board in the Control Box may be defective. Refer fault to

qualified service personnel.

8. Using a gauge or manometer, check gas pressure readings into

and out of the Air/Fuel Valve to ensure gas is getting to the

burner.

9. Remove the burner and inspect for any carbon or debris. Clean

and reinstall

FLAME LOSS

DURING RUN

1. Worn Flame Detector or cracked

ceramic.

2. Defective Differential Regulator.

3. Poor combustion calibration.

4. Debris on burner.

5. Blocked condensate drain.

1. Remove and inspect the Flame Detector for signs of wear or

cracked ceramic. Replace if necessary.

2. Check gas pressure readings using a gauge or manometer into

and out of the Air/Fuel Valve to ensure that the gas pressure

into and out of the valve is correct.

3. Check combustion calibration. Adjust as necessary.

4. Remove the burner and inspect for any carbon or debris. Clean

and reinstall.

5. Remove blockage in condensate drain.

HEAT DEMAND

FAILURE

1. The Heat Demand Relays on the

Ignition/Stepper board failed to

activate when commanded

2. Relay is activated when not in

Demand

1. Press CLEAR button and restart the unit. If the fault persists,

replace Ignition/Stepper (IGST) Board.

2. Defective relay. Replace IGST Board.

HIGH EXHAUST

TEMPERATURE

1. Defective exhaust sensor.

2. Carboned heat exchanger due to

incorrect combustion calibration

1. Measure the actual exhaust temperature and continuity of the

exhaust sensor. If the exhaust temperature is less than 475

o

F

and the exhaust sensor shows continuity replace the sensor.

3.

If exhaust temperature is greater than 500

o

F, check

combustion calibration. Calibrate or repair as necessary.

8

-5