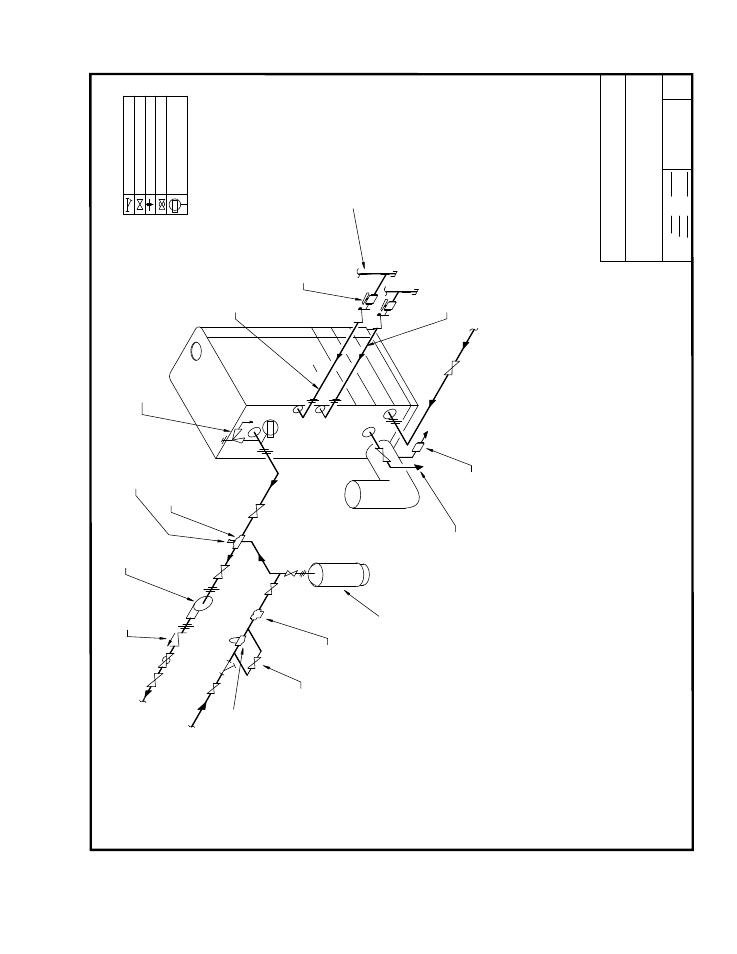

Appendix g - piping drawings, Aer co, Appendix g – AERCO BMK 1.5 LN Dual Fuel Jan 2009 User Manual

Page 108: Le ge n d

APPENDIX G

G-1

5) T

H

IS

IS A

TYP

ICAL

INST

ALL

A

TIO

N

D

R

AW

ING

. LO

CAL

COD

ES A

ND

AUTH

OR

ITIES

SH

OUL

D

BE

CON

SUL

T

ED

.

2)

SHE

LL D

R

AIN

VAL

VE A

ND

CON

D

EN

SAT

E DR

AIN

TRA

P

SH

OUL

D

BE

AR

RAN

G

ED

TO

PER

MIT

THE

FLU

IDS T

O

D

R

AIN

HEI

G

HT

18'

' ABO

VE

FLO

O

R.

4) L

O

CA

TE W

A

TE

R IN

LET

AND

OU

TLET

FIT

T

ING

S

(i

.e. U

N

ION

S, E

L

BO

WS,

ETC

.) A M

INIM

U

M

OF

6'

'

FRO

M

BO

ILE

R

E

L

EC

TRIC

CO

NNE

CTIO

NS

(SER

VIC

E

SW

ITC

H

ES

, CO

NDU

IT B

O

XES

) SH

OUL

D

LI

KEW

ISE

1

) FO

R AC

TUA

L

SI

ZES

AND

LOC

A

TIO

N

S

OF P

IPIN

G

AN

D O

T

HE

R C

O

NN

ECT

IONS

TO

THE

BOI

L

ER

, SEE

DIM

E

NS

ION

AL D

R

AW

ING

(AP

-A-73

9).

3) A

LL (*

) ITE

M

S

ARE

INCL

UDE

D S

EPAR

ATE

L

Y IN

SH

IPM

E

NT

FRO

M

F

A

CTO

R

Y

.

BE

6

'' A

W

A

Y

F

R

OM

SI

D

E

PA

N

E

L

S

.

NOT

ES:

S

ING

LE U

N

IT

INST

ALLA

TIO

N

D

U

A

L

FU

EL G

AS F

IRED

BO

ILER

BEN

CHM

A

R

K

1.5

MIL

. BTU

LO

W NO

x

AI

R

S

EPA

RAT

O

R

AUT

O

MA

TIC

AIR

VEN

T

1

-1/2" NPT

D

R

AI

N CO

NN.

L

INE SIZE

BYP

ASS

BAC

KFLO

W P

R

EV

ENT

E

R

DIAP

HRA

GM TYP

E

EXP

ANS

ION TAN

K

WA

T

E

R

SU

PPL

Y

* CON

D

EN

SAT

E

DR

AIN T

R

AP

P&

T

R

E

LIE

F

VA

LVE

(TY

P.)

PRE

SSU

RE

RED

UCIN

G

FILL

VAL

VE

HEA

T

ING

SYS

TEM

RET

URN

CH

E

C

K

VA

L

V

E

(T

YP.

)

H

EAT

ING

S

YST

EM

SUP

P

LY

S

YST

EM

PU

M

P

AT M

AX

IMUM

BT

U

/HR

INP

U

T,

MAI

N

TA

IN M

INIM

UM

G

AS

PRE

SSU

RE A

T

4.0" W

.C.

(FM

GAS

TRA

IN);

4.2" W

.C.

(IRI)

.

MAX

. GA

S

PR

ESS

URE

=

2.0 P

SIG

. (SE

E NO

TE

6)

* 2"

MA

NUA

L

SH

U

T

O

F

F

VA

L

V

E

DI

RT T

R

AP

G

AS S

U

PP

LY

FRE

E

LY

, BY

GRA

V

ITY

, TO

A C

O

NV

ENIE

NT

FLOO

R D

R

AIN

. R

E

LIE

F

VA

LVE

SHO

U

LD

BE P

IPED

VE

RTIC

ALL

Y

TO

A

FI

TTIN

G

S

TO P

R

EV

ENT

INT

E

RFE

R

EN

CE

WIT

H

RE

MOV

A

L O

F

B

OILE

R

PA

NEL

S

AN

D C

O

VE

RS.

ALL P

IPIN

G

A

N

D

N

O

R

T

H

VALE,

N

J

0

7647

INT

E

RN

A

T

IONA

L

, INC

.

AP

PD

.

DWN.

B

Y

SC

A

L

E

DA

T

E

DA

T

E

JK

NT

S

102

307

AER

CO

S

D

-A

-7

3

4

TE

MPE

R

AT

URE

GAU

G

E

P&T

PR

ESS

URE

&

BA

LANC

ING

VAL

VE

ISO

L

AT

ION VALV

E

UN

ION

Y S

T

RA

INER

LE

GE

N

D

RE

V

A

AT M

AXI

MUM

BTU

/HR

INP

UT,

MAIN

TAI

N

MI

N

IM

UM P

ROP

ANE

PR

ESSU

RE

A

T

4.0" W

.C.(

FM

GAS

TRA

IN);

4.2" W

.C.

(IRI).

MAX

. GA

S PR

ESS

URE

=

2

.0 P

SIG.

(SE

E NO

TE 6

)

PR

OPA

N

E S

U

PP

LY

6) W

H

EN

AV

AILA

BLE

GAS

PRE

SSU

RE I

S

GR

EAT

ER T

H

AN

2.0

PSIG

, A L

OCK

-UP

STY

L

E R

E

GU

LATO

R M

U

ST

BE

INST

ALLE

D

DO

WNS

T

RE

AM

OF T

H

E

2" MA

NUA

L SH

UTO

FF V

A

LV

E TO

BR

ING

THE

GAS

PRE

SSU

RE D

O

W

N

TO

2.0

PSIG

.

7) G

AS/P

R

OP

ANE

RA

TED

CHE

CK V

A

LV

ES R

E

QU

IRE

D

ON

LY F

O

R

DUA

L

FU

EL IN

STA

LLA

TION

. CH

ECK

VAL

VES

MUS

T

BE

SIZ

E

D F

O

R

1,5

00 CF

H (N

ATU

R

AL

GA

S) AN

D 6

00 CF

H (P

ROP

A

NE

). M

A

NU

FAC

T

UR

ERS

SUC

H

A

S

EC

LIPS

E CA

N BE

CO

NSU

L

TE

D FO

R

GA

S/PR

OPA

N

E R

A

TE

D C

H

EC

K VA

LVE

S

.