Troubleshooting – AERCO BMK 1.5 LN Dual Fuel Jan 2009 User Manual

Page 59

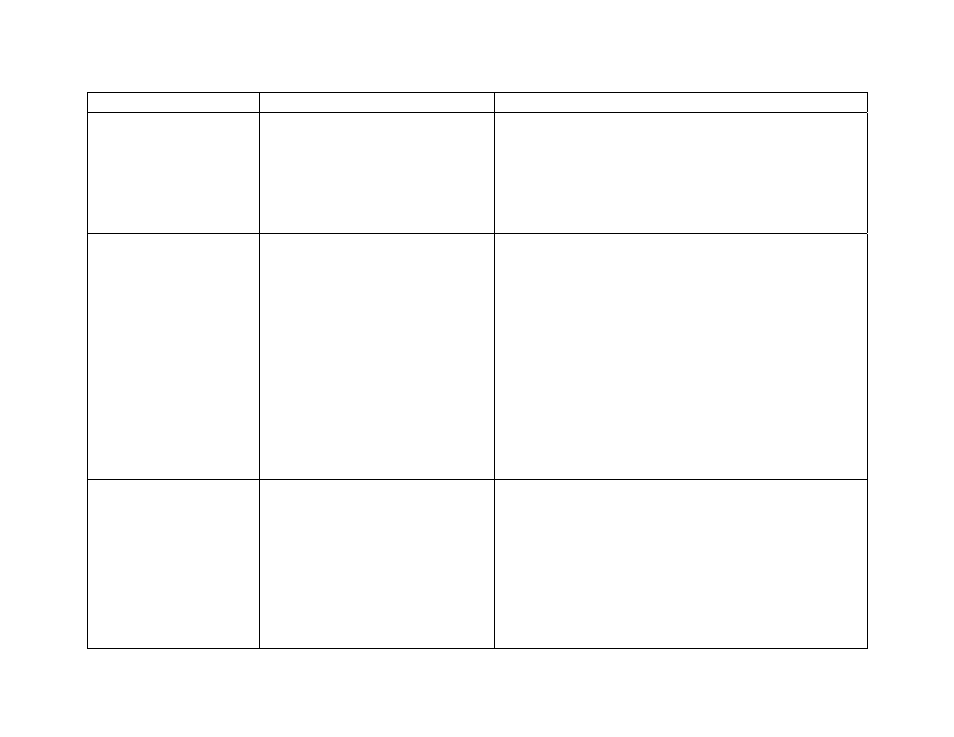

TROUBLESHOOTING

TABLE 8-1. BOILER TROUBLESHOOTING – Continued

FAULT INDICATION

PROBABLE CAUSES

CORRECTIVE ACTION

(continued)

17. Defective thermal overload contactor.

18. Current overload not set to the proper

current limit.

19. Fuel Selector Switch set to incorrect

position for fuel used or wrong Logic

Stick is installed in VFD.

17. Reset thermal overload contactor.Check position of Fuel

18. Check to ensure that the thermal overload contactor is set to

14 Amps.

19. Check the position of the Fuel Selector Switch and the installed

VFD Logic Stick to ensure the are correct for the fuel being

used.

AIRFLOW FAULT

DURING PURGE

1. Blower not running or running too slow

2. Defective Air Flow Switch

3. Blocked Air flow Switch

4. Blocked Blower inlet or inlet ductwork.

5. No voltage to switch from control box.

6.

PROBABLE CAUSES

from 3 to 17

for

AIRFLOW FAULT DURING

IGNITION applies for this fault

1. Start the unit. If the blower does not run check the blower solid

state relay for input and output voltage. If the relay is okay, check

the blower.

2. Start the unit. If the blower runs, check the airflow switch for

continuity. Replace the switch if there is no continuity.

3. Remove the air flow switch and inspect for signs of blockage,

clean or replace as necessary.

4. Inspect the inlet to the combustion blower including any ductwork

leading up to the combustion blower for signs of blockage.

5. Measure for 24 VAC during start sequence from each side of the

switch to ground. If 24VAC is not present refer to qualified

service personnel.

6. See

CORRECTIVE ACTION

from 3 to 17 for

AIRFLOW

FAULT DURING IGNITION

AIRFLOW FAULT

DURING RUN

1. Blower stopped running due to thermal

or current overload

2. Blocked Blower inlet or inlet ductwork

3. Blocked air flow switch.

4. Defective air flow switch.

5. Combustion oscillations.

1. Check combustion blower for signs of excessive heat or high

current draw that may trip thermal or current overload devices.

2. Inspect the inlet to the combustion blower including any ductwork

leading up to the combustion blower for signs of blockage.

3. Remove the air flow switch and inspect for signs of blockage,

clean or replace as necessary.

4. Measure the resistance of the switch for continuity with the

blower running. If there is an erratic resistance reading or the

resistance reading is greater than zero ohms, replace the switch.

5. Run unit to full fire f the unit rumbles or runs rough, perform the

combustion calibration procedures in Chapter 4.

8

-3