Gf-120, Benchmark 1.5ln low nox boiler – AERCO BMK 1.5 LN October 2012 User Manual

Page 81

CHAPTER 7

MAINTENANCE

PR1: 10/18//12 AERCO International Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288 Page 81 of 166

GF-120

OMM-0041 0E

Benchmark 1.5LN Low NOx Boiler

Installation, Operation and Maintenance Manual

STAGED

IGNITION

ASSEMBLY

FLAME

DETECTOR

IGNITOR-

INJECTOR

BURNER

PLATE

COMPRESSION

FITTING & ELBOW

FLAME

DETECTOR

GASKET

INDEXING

WASHERS

(QTY = 0-3

AS REQ’D)

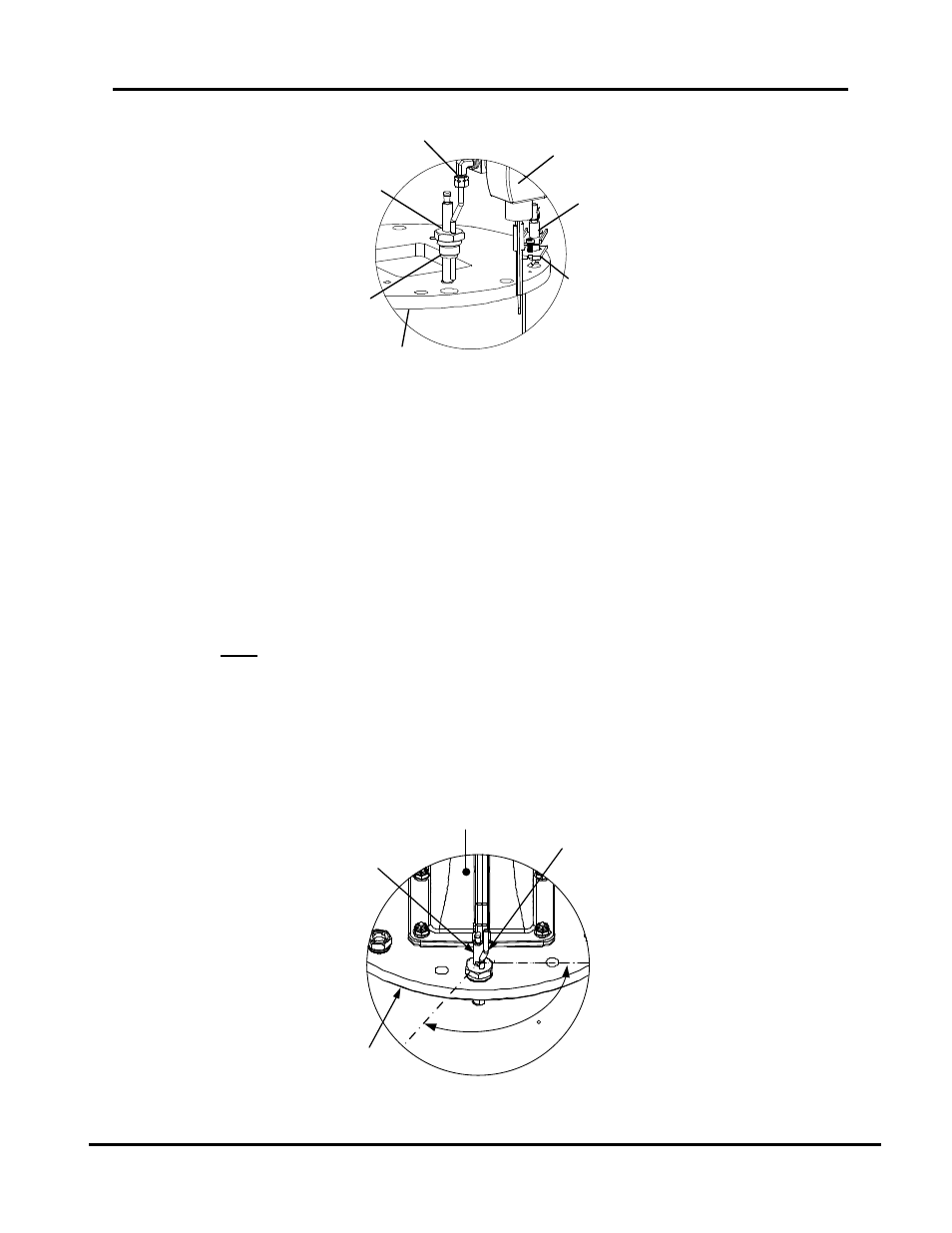

Figure 7-2

Igniter-Injector & Flame Detector Mounting Details

Next, loosen and remove the igniter-injector from the burner plate using a 1" open-end

5.

wrench.

Check the igniter-injector for evidence of erosion or carbon build-up. If there is evidence

6.

of substantial erosion or carbon build-up, the igniter-injector should be replaced. If

carbon build-up is present, clean the component using fine emery cloth. Repeated

carbon build-up is an indication that the combustion settings of the unit should be

checked. Refer to Chapter 4 for combustion calibration procedures.

Prior to reinstalling the igniter-injector, a high temperature, conductive, anti-seize com-

7.

pound must be applied to the threads.

NOTE

If a replacement igniter-injector (part no. 58023) is being installed, a

compression nut containing a built-in ferrule will be included with the

replacement part. If needed, 3 indexing washers are also included These

washers may be needed to properly position the gas injector tube of the

igniter-injector within the 120° angle range shown in Figure 7-3.

120

IGNITOR-

INJECTOR

GAS

INJECTOR

TUBE

BLOWER

BURNER

PLATE

Figure 7-3: Igniter-Injector Orientation